Durst Theta 76 User Manual

Page 9

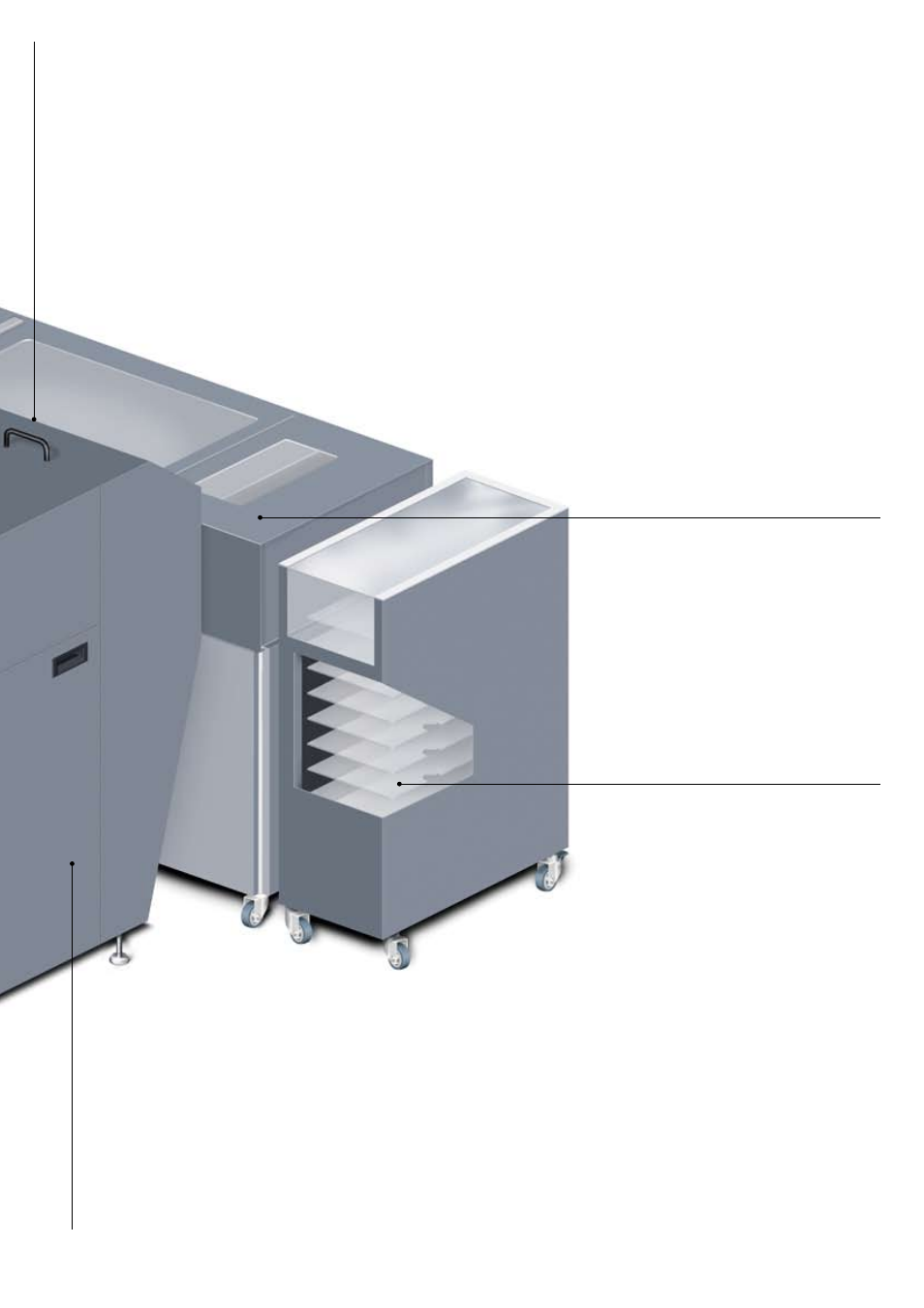

A sensitive subject: The latent image. We

have solved the problem without the usual

productivity loss and related loss of time as it

occurs at other manufactures. And this is how

we did it: The exposed material is continuously

transported through a “Print Puffer”, where

the latent image is stabilized prior to the transfer

to the processor. This results in a homogeneous

image production with a high repeat accuracy.

You receive images of highest quality without

any color drift.

At Durst no drums are used as in other systems.

Therefore you have the advantage of image sizes

up to 4 meter (13 ft.) length – ideal for panorama

prints in any length. And this is the procedure:

Our patented LED fiber optic light source exposes

continuously onto photo paper in rolls. Prints

are cut according to the selected print size prior

to feeding it into the paper processor. Customer

and lab information is printed on the back of the

image with the back printer.

The printing unit

Never again trouble with

the latent image

Infra Red Drier

RA4 Paper Processor

• In-line Y-Cuttter for print sizes up

to 30 cm (12 in.) width

• In-line Y-Cuttter for print sizes up

to 50 cm (30 in.) width

In-line Y-Cuttter for print sizes up

to 30 x 45 cm (12 x 18 in.).