Digital, automatic workflow, Durst fiber optic (dfo) technology – Durst Theta 76 User Manual

Page 5

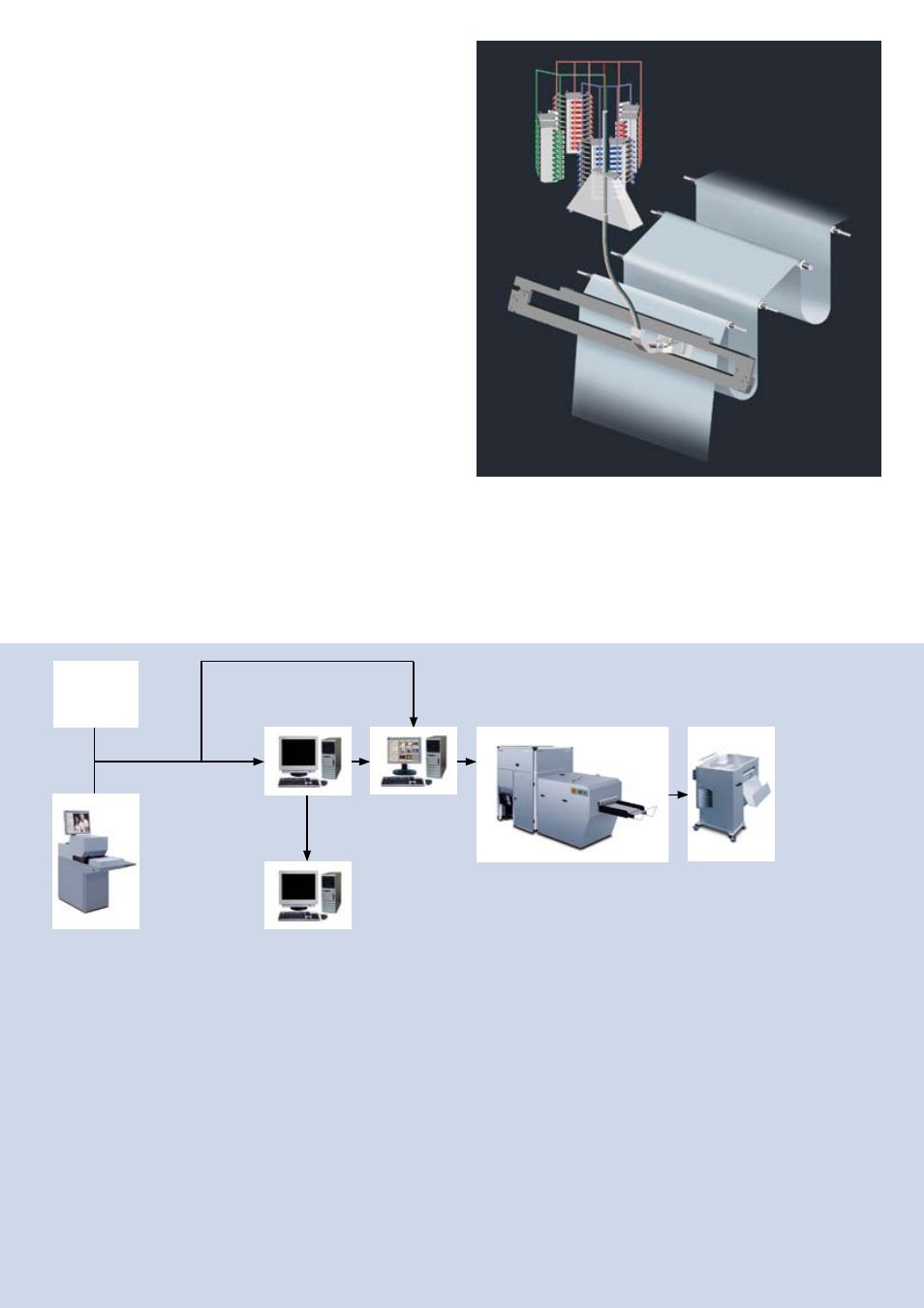

Digital, automatic workflow

The image data is automatically “retrieved” from the data server.

The scaling also occurs automatically – and without further

manual intervention, the ICC conversion, printing, processing,

cutting and sorting takes place. All this together really leads to

a fully automatic, digital workflow.

Durst Fiber Optic (DFO) Technology

The DFO technology is the heart of our system. Monochrome

LED’s (red, green, blue) produce light which is projected as pixels

over glass fiber cable and optics line-by-line with 254 ppi printing

resolution/256 levels onto photo sensitive material.

The DFO technology becomes unique through its media calibration

system consisting of densitometer, scanner and the corresponding

software whereby the majority of materials are calibrated to

an optimum. The DFO technology features an LED light source

with an extremely long life time of close to 100.000 hours,

thus combining proven Durst image quality at extremely low

maintenance costs.

External

image data

entry

Scanning with the Sigma 67

Job preparation

with the Durst

Print Terminal

CD-Robot System

Job preparation

or auto spooling

with the Theta

76 Workstation

Theta 76/76 HS

Simultaneous printing/processing

Optional cutting

and sorting with

the Fotoba In-Line

Y Cutter/Sorter

up to 30 x 45 cm

(12 x 18 in.)

Optional cutting

with the Fotoba

In-Line Y Cutter

up to 50 x 70 cm

(20 x 30 in.)