Troubleshooting guide – Desa 496 User Manual

Page 24

24

105635

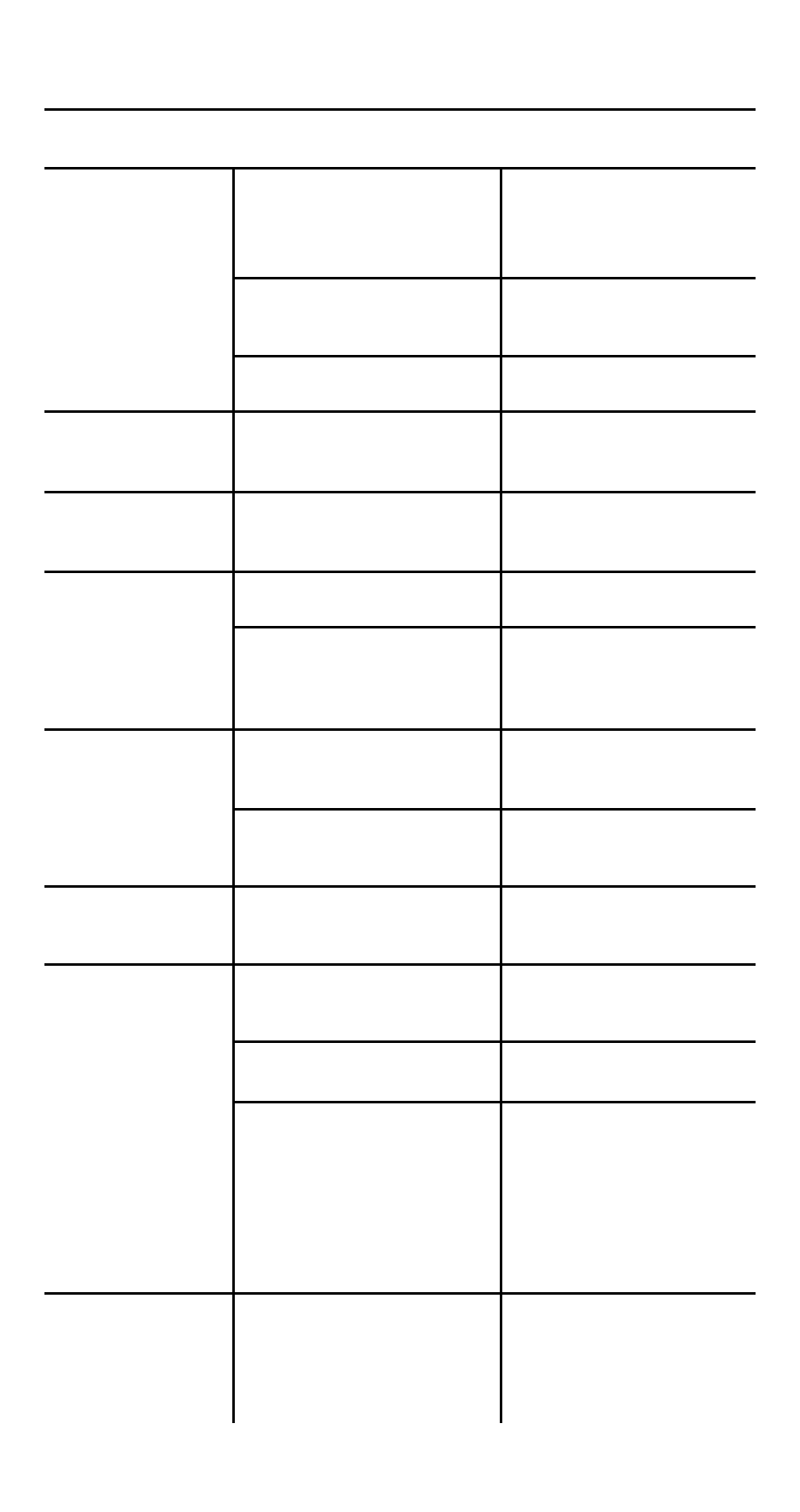

Troubleshooting Guide

Piston hangs out

of muzzle.

Overdriven

fastener.

Piston jammed.

Power load strip will

not advance.

Reduction or loss

of power.

Tool does not

completely depress.

Tool does not fire.

Opening and clos-

ing of barrel or

pushing down on

tool, etc. is not

smooth but is

rough or binds.

PROBLEM

Tool overdriven.

Piston not properly

assembled in relation to

stop.

Broken piston or piston ring.

Excessive power.

Overdriving of fastener (see

above).

Advance bar or spring

damaged

Tool dirty.

Piston not returning to full

rear position.

Worn piston ring or broken

piston.

Misassembled or damaged

sear, firing pin parts, or

guide.

Failure of tool to depress

completely.

Piston not fully reset.

Dirt buildup on sear not

allowing proper penetration

of firing pin or worn firing

pin.

Lack of proper cleaning.

POSSIBLE CAUSE

Tap piston on hard surface

until piston is pushed back

into the guide. (See

Over-

driven Fastener

below)

Remove barrel assembly

(see pages 18-20). Replace

all damaged or missing parts.

Replace piston or piston ring

or take tool to your distributor.

Change either to next lower

power load or next longer

length fastener.

Remove barrel assembly

(see pages 18-20). Replace

other parts if damaged.

Replace advance bar or

springs.

Clean tool. Notice: Do not

attempt to clean power load

strip channel with wire brush.

You may damage tool.

Barrel must be opened to the

full extended position to

properly position piston.

Replace piston and/or piston

ring or take tool to your dis-

tributor.

Remove firing pin guide and

check all parts for correct fit

assembly.

See data listed under

Tool

does not completely de-

press,

above.

Fully reset piston. See step 1

under

Operation

, page 14.

Check firing pin mark on

power load. Clean firing pin

guide, sear and firing pin. Re-

place worn or damaged

parts. Notice: Do not attempt

to clean power load strip

channel with wire brush. You

may damage tool.

Inspect and clean complete

tool. Replace worn or dam-

aged parts. Notice: Do not

attempt to clean power load

strip channel with wire brush.

You may damage tool.

REMEDY