Commissioning, 7commissioning, 1 general – Dimplex LA 16TR User Manual

Page 7: 2 preparatory steps, 3 procedure

7

COMMISSIONING

7

COMMISSIONING

7.1

General

To ensure proper commissioning it should be

carried out by an after-sales service authorized by

the manufacturer. Only then can an extended

warranty period of 3 years in total be granted (cf.

Warranty service).

7.2

Preparatory Steps

Prior to commissioning, the following items need to

be checked:

- All connections of the heat pump must have been

made as described in Chapter 6.

- In the heating circuit all valves that could impair

the proper heating water flow must be open.

- T h e a i r i n t a k e / d i s c h a r g e p a t h m u s t b e

unobstructed.

- The sense of rotation of the fan must correspond

to the direction of the arrow.

- An operating mode must have been set on the

remote control.

- Proper condensate drainage must be ensured.

7.3

Procedure

The

start-up of the heat pump is effected via the

remote control.

Where an overflow valve is fitted to assure the minimum

heating water flow rate, the valve must be set in

accordance with the specific requirements of the heating

installation. An incorrect setting may result in various

error symptoms and an increased electric power

consumption. To correctly set the overflow valve, the

following procedure is recommended for the "heating

mode":

Close all of the heating circuits that may also be closed

during operation (depending on the type of heat pump

usage) so that the least favourable operating state -

with respect to the water flow rate - is achieved.

Typically these are the heating circuits of the rooms

on the building's south and west sides. At least one

heating circuit must remain open (e.g. bathroom).

The overflow valve is to be opened to such an extent

that based on the current heat source temperature

the maximum temperature spread between heating

supply and return flow temperature is obtained, as

indicated in the table that follows. The temperature

spread should be measured as closely to the heat

pump as possible. In mono-energetic systems, the

electric heating element is to be deactivated.

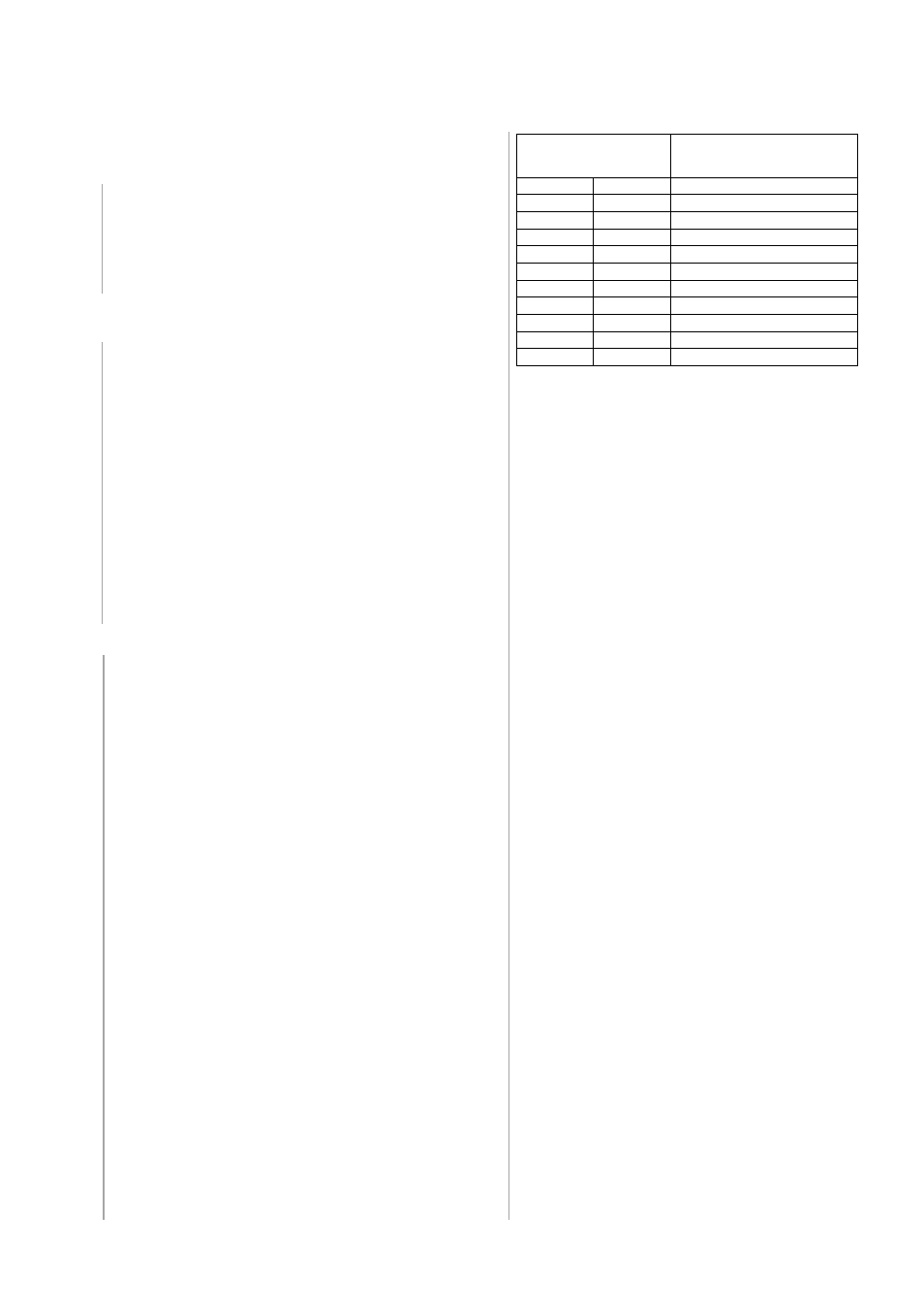

Heat source temperature

from to

max. difference between

heating water supply and

return temperature

-20 °C

-15 °C

4 K

-14 °C

-10 °C

5 K

-9 °C

-5 °C

6 K

-4 °C

0 °C

7 K

1 °C

5 °C

8 K

6 °C

10 °C

9 K

11 °C

15 °C

10 K

16 °C

20 °C

11 K

21 °C

25 °C

12 K

26 °C

30 °C

13 K

31 °C

35 °C

14 K

The following procedure must be observed so that

the commissioning activities can be carried out

without any problems:

a)

Close all heating circuits.

b)

Open the overflow valve all the way.

c)

W a i t u n t i l t h e b u f f e r t a n k h a s r e a c h e d a

temperature of approx. 25 °C.

d)

Subsequently, slowly reopen the valves of the

heating circuits, one after the other, in such a

w a y t h a t t h e h e a t i n g w a t e r f l o w r a t e i s

continually increased by slightly opening the

related heating circuit. When so doing, the

heating water temperature in the buffer tank

must not fall below 20 °C so that the heat pump

can be defrosted at any time.

e)

Once all heating circuit are fully open and a

heating water temperature of approx. 20 °C is

maintained in the buffer tank, the minimum flow

rate must be set on the overflow valve and the

heating circulating pump.