Adams Condensing Oil-Fired Furnace User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

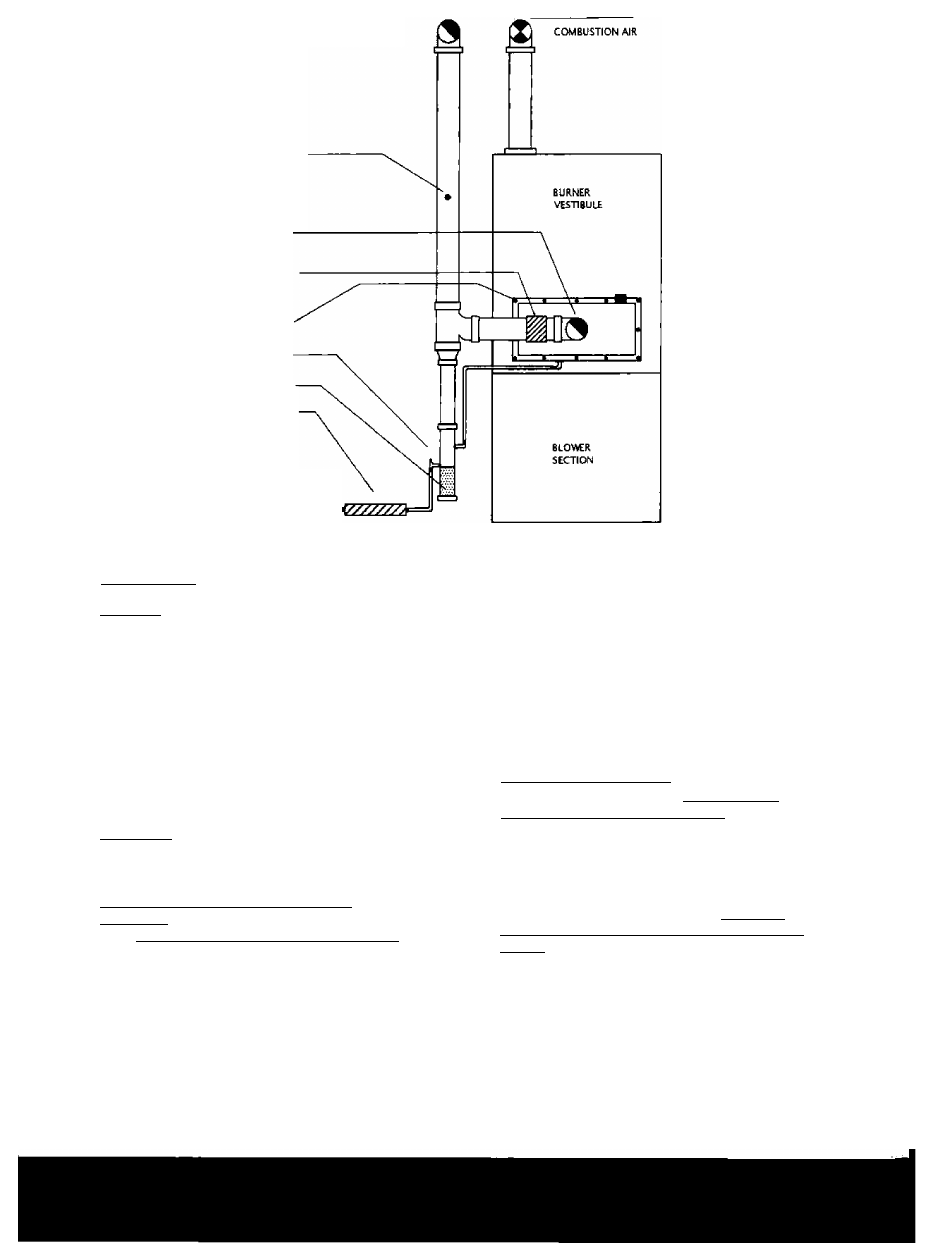

FLUE PRODUCTS

MAKE HOLE HERE

F0RC02 MLASUREME^fT,

SMOKE AND TEMPERATURE

READINGS

SEAL WITH RTVSIUCONE

APPROXIMATELV 18’ABOVE

CENTERLINE OF TEE

DO NOT USE CEMENT

AT METAL COLLAR

STAINLESS/RUBBER

QUICK CONNECT COUPLER

CONDENSATE COLLECTOR

VENT TO ATMOSHPERE

PREFILL TRAP WTH WATER

CONDENSATE NEUTRAUZER

NEUTRALIZER MUST LAY

HORIZONTALLY

REPLACE AT THE BEGINNING

Of EACH HEATING SEASON

TO FLOOR DRAIN

OR CONDENSATE PUMP /¿=

Note:

Furnace

may be

vented from

left OF right

side.

IX. OIL LINE

GENERAL

The furnace rating plate includes the approved

furnace input rating and fuel types. The furnace

must be equipped to operate on the type of oil

applied.

CAUTION I

TO PREVENT UNRELIABLE

OPERATION OR EQUIPMENT

DAMAGE, THE OIL LINE PRESSURE

MUST BE SET AT 140 P.S.I.

OIL TANK

Oil storage tanks must be selected and installed in

compliance with applicable codes; in the United

States, NFPA31.

Standard for the Installation of Oil Burning

Equipment. Chapter 2, and in Canada, CAN/CSA-

B139, Installation Code for Oil Burning Equipment.

Section 6. Observe all local codes and by-lays. In

general, the oil tank must be properly supported and

remain stable in both empty and full conditions. The

oil tank must be fitted with vent and supply pipes to

the outdoors. Refer to the above-mentioned codes

for sizing. The vent pipe must be no less than 1 %

inches I.P.S., and terminate with an appropriate vent

cap in a location where it will not be blocked.

■7

The fill pipe must be no less than 2 inches I.P.S..

and terminate with an appropriate cap In a location

where debris will not enter the fill pipe during oil

delivery.

If located indoors, the tank should normally be in the

lowest level, (cellar, basement, etc.), it must be

equipped with a shut-off valve at the tank outlet used

for the oil supply. The oil tank must be located as to

not block the furnace/room exit pathway. Observe

all clearances specified in the above-mentioned

codes.

PIPING INSTALLATION

In the United States, NFPA 31, Standard for the

Installation of Oil Burninq Equipment. Chapter 2.

In Canada, the entire fuel system should be installed

in accordance with the requirements of CAN/CSA

B139, and local regulations. Use only approved fuel

oil tanks, piping, fittings, and oil filters.

Ensure that all fittings used in a copper oil tine

system are high quality flare fittings. Do not use

compression fittinqs Do not use Teflon tape on any

fittings.

Pressurized or gravity feed installations must not

exceed 3 PSIG. Pressures greater than 10 PSIG

may cause damage to the shaft seal. If the height of

the oil stored in a tank above the oil burner exceeds

11 ^ feet, it may be necessary to use a pressure

regulating device approved for this purpose.

15