Standard furnace connections, Vent/flue pipe, Nt/flue and combustion air pipe lengths – Adams Condensing Oil-Fired Furnace User Manual

Page 11: Vent/fiue atkl combustion air pit>e terminations

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

STANDARD FURNACE CONNECTIONS

It is the responsibility of the installer to

ensure that the piping connections to the

furnace are secure, airtight, and adequately

supported.

All furnaces are shipped with a combustion

air connection on the cabinet exterior and a

flue connector on the inside of the cabinet

on the condensate collector box.

VENT/FLUE PIPE

Vent/flue pipe can be secured to the

vent^ue coupling using the rubber coupling

and worm gear hose clamps provided with

this furnace (see “Standard connections"

figure). The rubber coupling allows

separation of the vent/flue pipe from the

furnace during servicing.

Combustion Air and Vent piping should be

routed in a manner to avoid contact with

refrigerant lines, metering devices,

condensate drain lines, etc. If necessary,

clearances may be increased by utilizing two

45 degree Long-Sweep Elbows and creating

an “S” joint to provide additional space at

connection locations. This joint can be

rotated on the fitting to establish maximum

clearance between refrigerant lines,

metering devices, and condensate drain

lines, etc. This joint is the equivalent of one

90 degree elbow when considering elbow

count.

NOTE:

Do not use other commercially

available “no hub connectors" due to

possible material conflicts. Theventfflue

pipe can also be secured usirrg a PVC or

ABS elbow or coupling using the appropriate

glue (see Section VI, Materials and Joining

Methods).

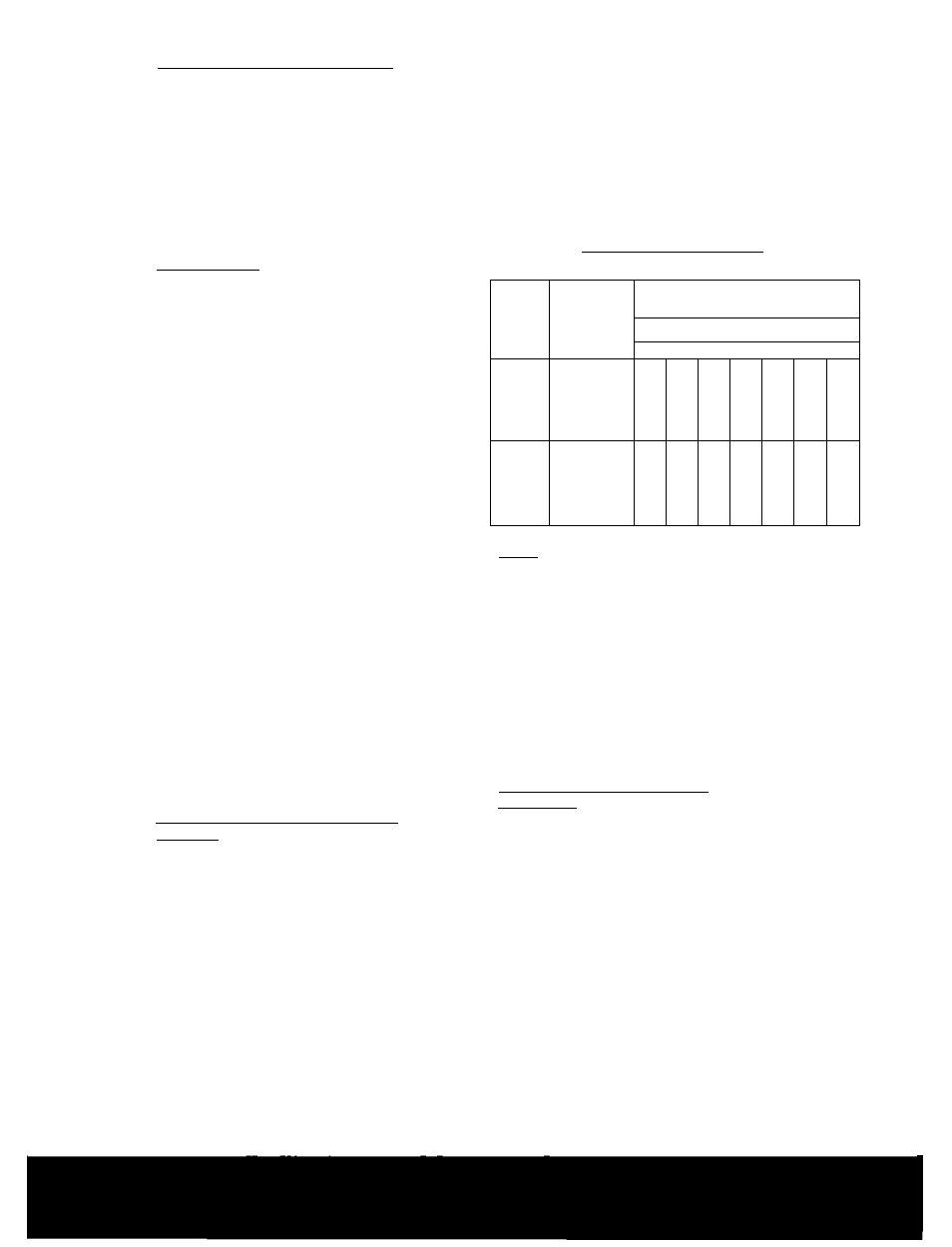

\^NT/FLUE AND COMBUSTION AIR PIPE

LENGTHS

Refer to the following table for applicable

length, elbows, and pipe diameter for

construction of the vent/flue and combustion

air intake pipe systems of a direct vent (dual

pipe) installation. The number of elbows

tabulated represents the number of elbows

and/or tees in each (Vent/Flue &

Combustion Air Intake) pipe. Elbows and/or

tees used in the terminations must be

included when determining the number of

elbows in the piping systems.

If the combustion air intake pipe is to be

installed above a finished ceiling or other

area wrfiere dripping of condensate will be

objectionable, insulation of the combustion

air pipe may be required. Use W thick

closed cell foam insulation such as Armaflex

or Insultube where required.

Non-Direct or Direct Vent (Dual Pipe)

Three (3) inch Pipe Diameter

Maximum Allowable Length of Vent/Flue and

Combustion Air Intake Pipe (ft)

Unit

input

BTU

Vent/fiue/Air

Intake Pipe

Termination

Maximum Allowable Length of

Vent/Flue Pipe (ft.)

Number of Elbowe

2 3 4 5 6 7 8

50.000

75.000

100.000

125.000

Standard

68

65

62

59

56

53

50

50.000

75.000

100.000

125,000

Alternate

55

52

49

46

43

40

37

Notes:

1

.

2

.

3.

4.

Minimum requirement for each vent

pipe is five (5) feet in length and one

elbow/tee.

Tee used in the vent/flue tennination

must be included when determining

the number of elbows in the piping

system,

3" diameter

Increased Clearance Configurations

using (2) 45 degree Long Sweep

elbows should be considered

equivalent to one 90 degree elbow.

Vent/Fiue atKl combustion Air Pit>e

Terminations

The vent/flue and combustion air pipes

may terminate vertically, as through a

roof, or horizontally, as through an

outside wail. Vertical pipe terminations

should be as shown in the following

figure. Refer to Section VI Vent/Flue

Pipe and Combustion Pipe Termination

Locations for details concerning location

restricfions. The penetrations through

the roof must be sealed tight with proper

flashing such as is used with a plastic

plumbing vent.

10