Operation, Maintenance, Filter cartridge replacement procedure – Amerec ASX100 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Operation

With adequate pressure, normal operation of the ASXlOO System is completely automatic. Dependable operation

involves only monitoring of outlet pressure, periodic filter changes and service documentation.

Maintenance

The only routine maintenance your ASXlOO System should ever require is periodic filter cartridge changes or replace

ment sump O-rings. Filter changes are necessary for optimum performance of your foodservice equipment. If the

system sizing recommendations have been followed the ASXlOO System is designed to provide a twelve (12) month

filter replacement interval on most tap water.

Filter Change Frequency

Several sihiations will mandate filter changes. Complete filter sets should be changed when any of the following ap

ply:

• Twelve (12) Months have passed since unit installation or previous filter change.

• Reduced water flow.

If filter change frequency is less than 12 months due to pressure drop, it may be necessary to add additional prefiltra

tion or evaluate system sizing recommendations.

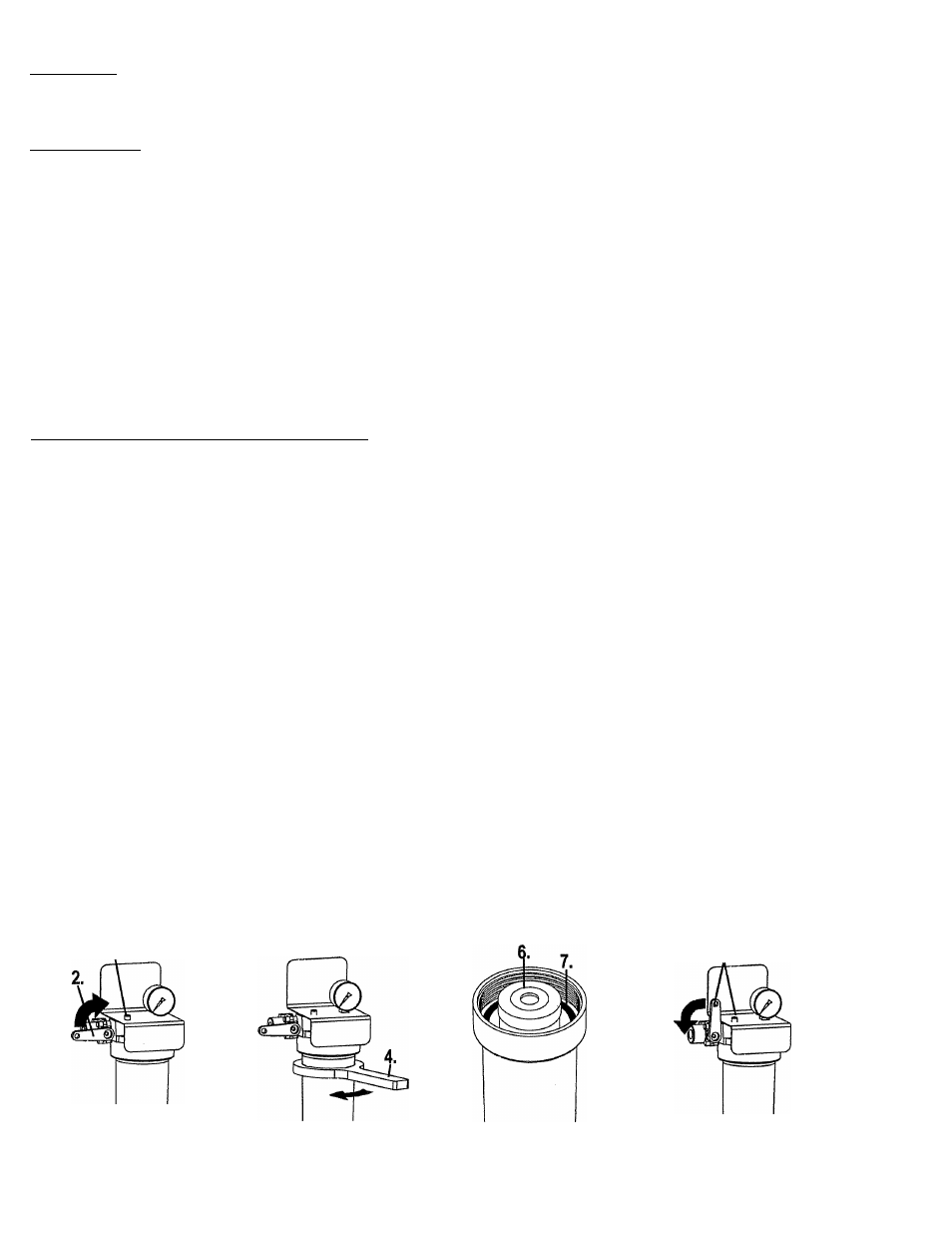

Filter Cartridge Replacement Procedure

IMPORTANT; Determine whether all equipment connected to the ASXlOO System must be turned off prior to shut

ting off water supply from filters.

1.

2

.

3.

4.

5.

6

.

7.

10

.

11

.

If required, turn off equipment.

Turn OFF water to ASXlOO System by closing Inlet Ball Valve.

Press the red button to release pressure.

Remove housing(s) - use filter wrench if necessary.

Clean inside of housing sumps with warm water. If desired, disinfect housings using a

teaspoon of household bleach in a filter bowl of water. Let stand 5 minutes, and then

discard.

Insert new cartridge(s) into filter housings. Match cartridge model numbers to model

numbers on bracket.

Make certain the O-ring is properly positioned and reinstall filter housings (hand tighten

only). Check O-ring for damage and replace if damaged or distorted.

Slightly open the inlet ball valve; push the red pressure relief button to release trapped air

until a small amount of water comes out - release the red button and fully open the ball

valve.

Open the flush valve downline from the filter housing (if equipped) and flush the new

cartridges to drain or bucket for five (5) minutes or until water runs clear. If no flush

valve is present, disconnect line from equipment to flush to drain.

VERY IMPORTANT: With water supply inlet valve OPEN and water flow confirmed, turn on

connected equipment. Failure to supply water to equipment may cause serious damage.

Record filter change on the service log.