Pilot, V. charging the system with water – Bryant 451A User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A wrench-type shut-off valve should be installed

in the gas line within sight of, and convenient to,

the 451. Provide a ground joint union upstream of

the combination regular shut-off, and preferably

outside the unit.

Install a drip leg trap in the gas supply riser lead

ing to the unit. After gas pipe connections have

been made, purge the lines and check for leakage.

Use a soap and water solution or other such mater

ial.

Never use matches, candles, flame or other source

of ignition to check leakage.

PILOT

Light the pilot using the procedure outlined on the

Lighting Instruction Plate attached to generator.

The pilot flame should be soft blue in color. The

flame should be of sufficient length to provide good

impingment on the unimetal element of the Bryant

pilot. Flame should extend upward between the

carry-over ports of the two adjacent burners.

If the pilot flame does not have the appearance

described above, it may be adjusted by means of

the manual pilot shut-off valve which is equipped

with an adjustable screw. Turn the handle to the

full-open position and remove the screw cap on the

valve handle, thus exposing the adjustable screw.

Turn adjusting screw until flame has the desired

appearance. Replace screw cap.

V. CHARGING THE SYSTEM WITH WATER

Caution: Do not run the pump

dry. Freezing condL

tions will not damage the pump; however, do not

attempt to operate the pump when chiller or chilled

water lines are frozen.

1. Turn off main manual gas shut-off valve.

2. Remove the filler cap from water chiller tank.

3.

Disconnect line at chiller inlet. (When install

ing the chilled water lines, it is advisable to leave

this connection open until lines have been flushed).

4.

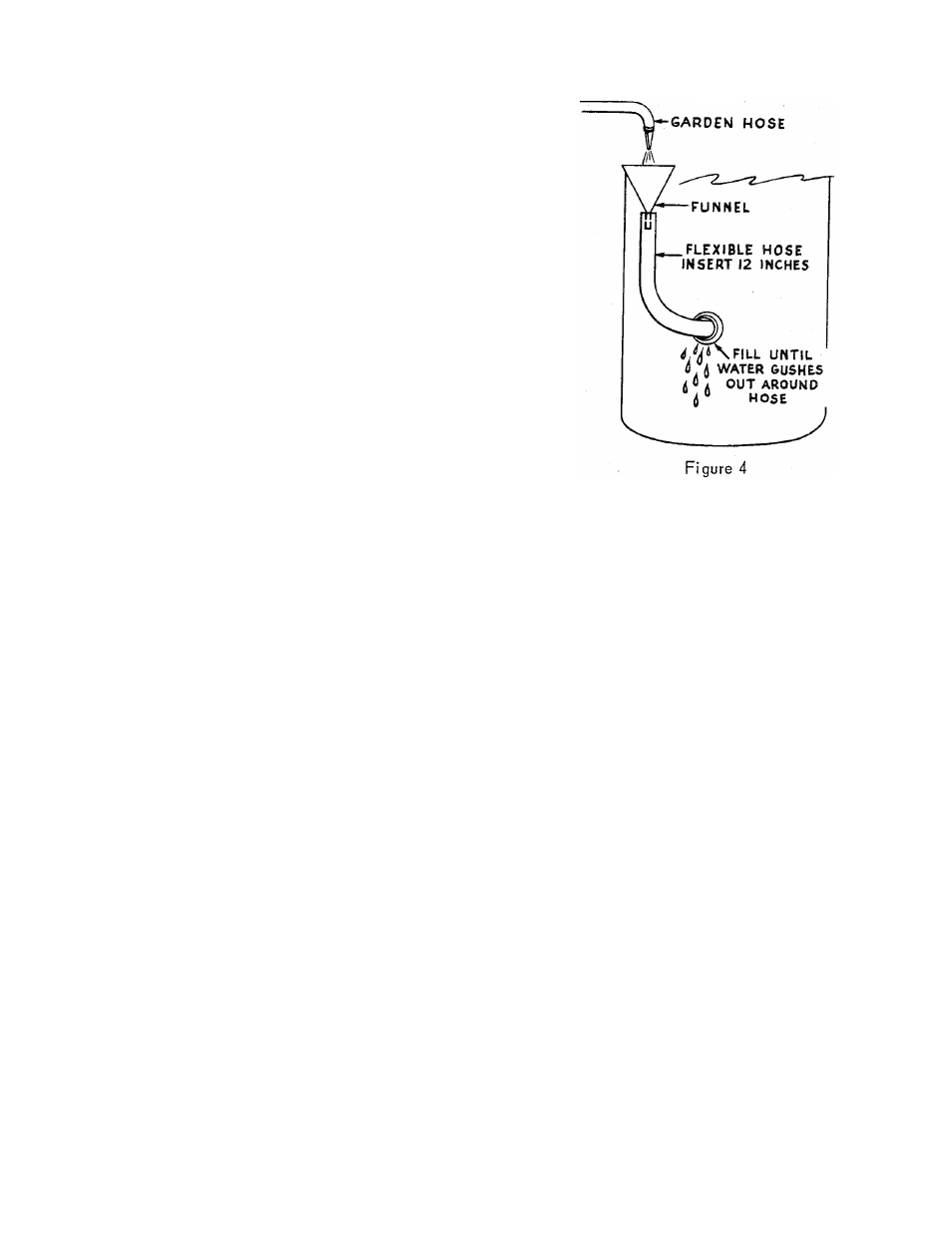

Fill the tank with tap water by inserting a

garden hose into the filler tube about 12 inches

and running water into the chiller until it gushes

out around the hose. See Figure 4.

5.

Start pump. Allow pump to operate until all

foreign matter has been flushed from the pipes.

Continue to supply water to the tank during this

cleaning period.

Note: If water does not circulate when the pump

is started, air may be trapped in the pump. Bleed

the air from pump through the 1/8" slotted head

bleed valve located on top of the pump discharge.

Open valve with screw driver. Close valve when

the trapped air is removed and water appears.

6. Turn off pump and hose. Make pipe connection

to chiller inlet.

7.

Turn on hose and fill tank until water gushes

out around hose. Remove hose and replace filler

cap.

8. Start pump and while water is circulating, check

for leaks throughout the chilled water system.

9. Stop pump and remove filler cap. Insert one end

of a piece of water hose into the tank at least 12".

Insert a clean plastic or metal funnel in the other

end of the hose.

10. Start pump and pour carton of borax into funnel.

Flush borax into chiller with water from water

hose used for filling until tank over-flows. Remove

hose and replace filler cap. The package of borax

supplied is sufficient for chilled water systems

containing up to 20 gallons of water. For systems

- 5-

EH 451