B. pipe length and diameter – Bryant 451A User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TABLE

Nominal

Pipe Size

Inches

Allowable Distance* between Coil and Chiller

Polyethy ene Pipe

Copper Pipe

Galvanized Pipe

Size 36

Size 54

Size 36

Size 54

Size 36

Size 54

3/4

40'

—

35'

—

25'

—

1

150'

45'

140'

40'

90'

30 '

1-1/4

530'

145'

360'

100'

370'

90'

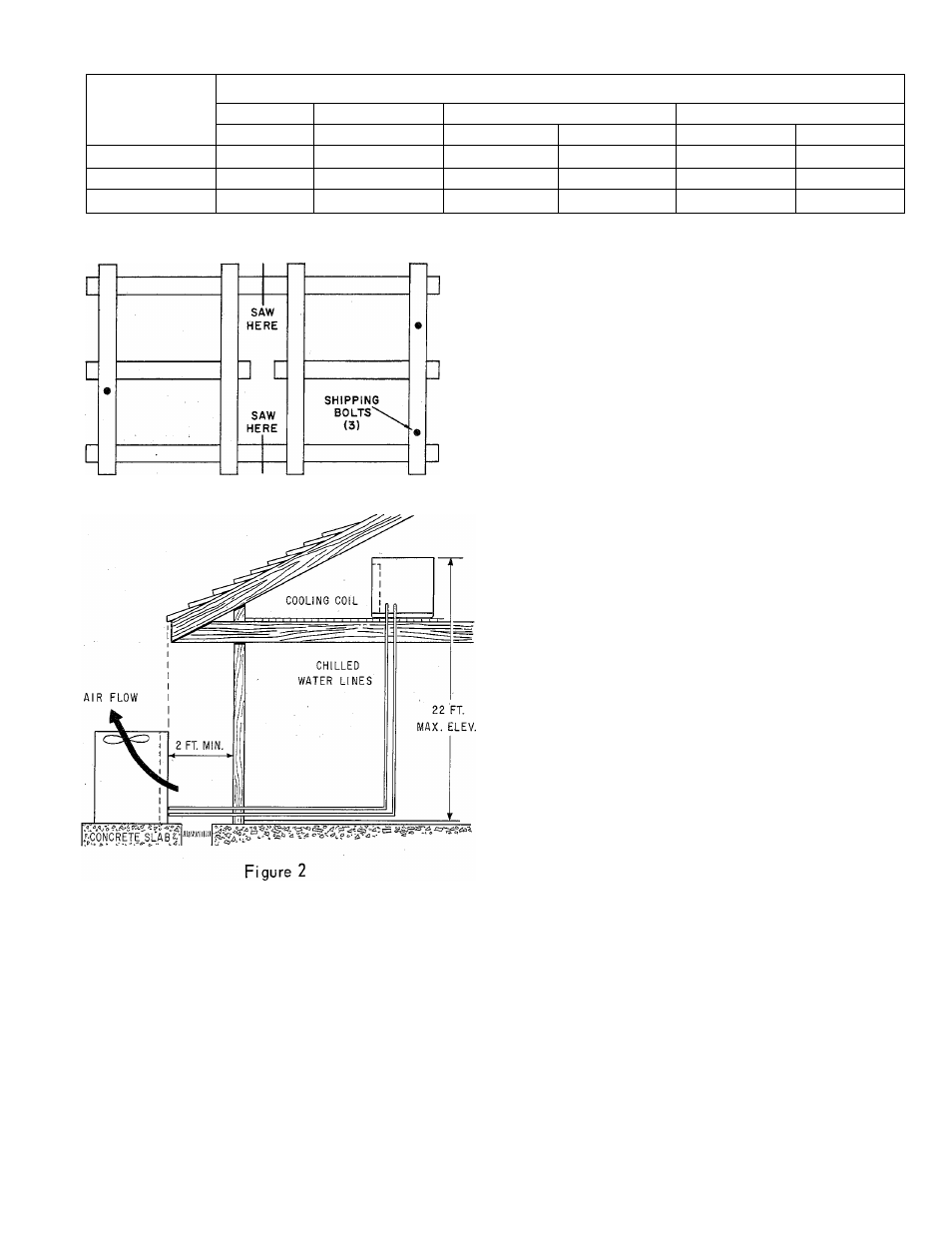

* Note: Values shown in above table are for one direction only. The total length of pipe from chiller to coil

and return would be double the above table values. The above table applies to single unit installations only.

Figure 1

II. CONNECT CHILLED WATER LINES

A.

MATERIALS

Refer to section on “Cold Weather Protection” at

the end of this instruction.

1. Piping

a. Polyethylene Plastic Pipe - use medium density

flexible pipe whose wall thickness approximates

Schedule 40 pipe (Commercial Standard CS 197-60).

Pipe must be virgin plastic. Do not use pipe manu

factured from re-claimed plastic.

□

AVOID

OPEN

WINDOWS

SLEEPING

QUARTERS

□

AVOID

'

e l l s

"

GARAGE

LIVING

AREA

□

GOOD

LOCATION

Figure 3

b. Copper - satisfactory substitute.

c. Galvanized - satisfactory substitute.

2. Fittings

a. Nylon - use when possible.

b. Brass - satisfactory substitute.

c. Galvanized - satisfactory substitute.

B. PIPE LENGTH AND DIAMETER

Table I shows maximum length of pipe of different

diameters that can be used between the pump dis

charge and the coil inlet and still maintain mini

mum allowable (design) water flow rate.

1. Multiply table values by two to obtain the total

length of pipe from chiller to coil ond return.

2.

Length is measured along the pipe path and

therefore includes vertical distance between the

water coil and the chiller.

3. Lengths shown in Table I are based on using a

total of eight elbows in the entire water line

(chiller to coil and return). Lengths are predicated

on the use of a Bryant matching water coil. For

greater distances use larger pipe or add a pump.

- 3 -

EH 451