B. pipe length and diameter, C. insulation, D. height of coil above absorption unit – Bryant 108-451 User Manual

Page 3: E. water coil connections

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

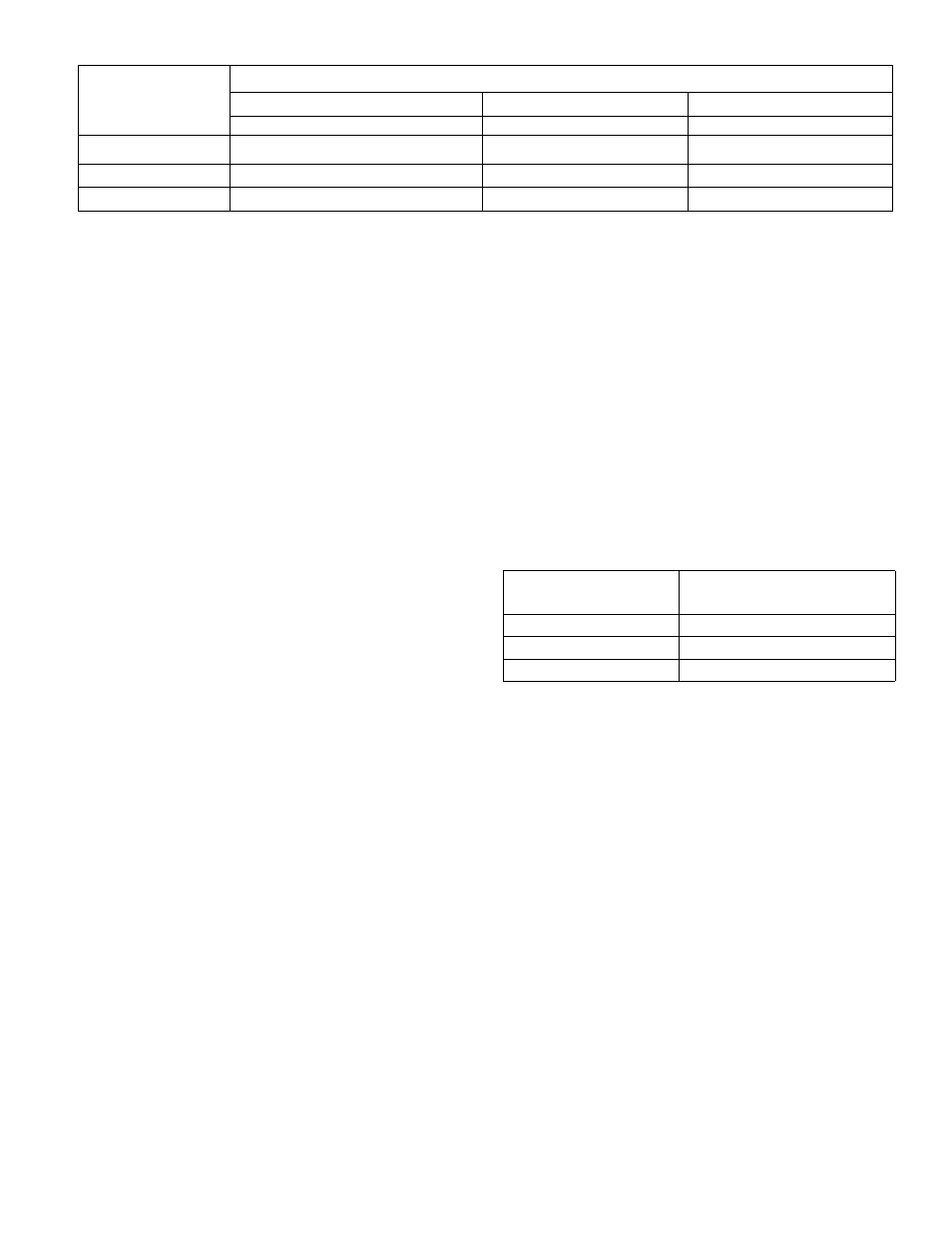

Table I

Nominal

Pipe Size

Inches

Allowable Distance* Between Coil and Chiller

Polyethylene Pipe

Copper Pipe

Galvanized Pipe

Size 108

Size 108

Size 108

1

48'

67'

72'

IV

a

272'

210'

285'

IV

2

610'

492'

642'

* Note: Values shown in above table are for one direction only. The total length of pipe from chiller to coil

and return would be double the above table values. The above table applies to single unit installations only.

B. PIPE LENGTH AND DIAMETER

Table I shows maximum length of pipe of different

diameters that can be used between the pump dis

charge and the coil inlet and still maintain mini-,

mum allowable (design) water flow rate.

1. Multiply table values by two to obtain the total

length of pipe from chiller to coil

and

return.

2.

Length is measured along the pipe path and

therefore includes vertical distance between the

water coil and the chiller.

3. Lengths shown in Table I are based on using a

total of eight elbows in the entire water line (chil

ler to coil and return). Lengths are predicated on the

use of a Bryant matching water coil. For greater

distances use larger pipe or add a pump.

C. INSULATION

1. Insulate supply and return lines separately.

2. Material should be of good quality and be covered

with a good vapor barrier. Armaflex or equivalent is

recommended.

Wall thickness:

1/2'' wall thickness - south of 40° N. latitude

3/8" wall thickness - north of 40° N. latitude

D. HEIGHT OF COIL

ABOVE ABSORPTION UNIT

Maximum vertical distance from chiller outlet to

top

of coil is 49 feet. For greater heights, a greater

pumping head is required. Increasing the pipe size

will not help.

E. WATER COIL CONNECTIONS

1. If cooling coil is used in connection with heat

ing unit, install cooling coil in parallel with or

downstream of heating unit to avoid condensation in

the heating unit.

2. If coil is located in warm air stream, do not

connect polyethylene pipe directly to coil. Connect

a minimum of 24 inches copper or galvanized pipe

to both the coil inlet and outlet. Then connect the

plastic pipe to these nipples.

3. On installations where the outside piping freezes

and the coil is in a heated air stream, precautions

must be taken to provide for water expansion. The

connecting polyethylene plastic pipe acts as an

expansion vessel if there is enough footage of this

pipe in the heated space (space not subject to

freezing). The following table shows the minimum

lengths (total inlet and outlet) of plastic piping of

various diameters that are required for both sizes

of coils to provide adequate expansion volume.

Nominal Pipe Size

Inches

Length of Plastic Pipe

in Feet

1

70

VA

40

IV

2

29

If the total plastic chilled water line footage in the

heated space is not as long as the minimum values

shown in the table, tee a vertical pipe of sufficient

volume into either of the coil connections to provide

for expansion, or the line should be drained.

III. ELECTRIC CONNECTIONS

1. Make all electric connections in accordance with

the National Electrical Code and any local ordi

nances or codes that might apply.

2.

Provide a separate power supply for the air

conditioner.

3. Provide a fused disconnect switch within sight

of and not more than 50 feet from the absorption

unit. Use 35 amp standard fuse.

4. The absorption unit is shipped fully wired from

the factory. Connection of 230V power and low volt

age connection to the thermostat control are re

quired in the field. Before proceeding, inspect

factory wiring for loose connections which may have

resulted during shipment.

- 3 -

108/451