Bryant 450D User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

?. CHAliGING THE SYSTEM WITH WATER

VI. CHECK-OUT AND OPERATION

Caution:

Do not ran the pump dry. Freezing conditions

will not damage the pump, but do not attempt to operate

pump when chiller or chilled water lines are frozen.

1. Remove belt from condenser fan.

2. Turn off main manual gas shut-off valve.

3.

Remove top cover from water chiller tank. Remove

container of chilled water additive stored in tank.

4.

Fill tank with tap water until distribution pan at top

is covered with water. A garden hose is useful for this

operation.

5.

Disconnect line at chiller inlet. (When installing the

chilled water lines, it is advisable to leave this con

nection open until lines have been flushed). Start pump.

Allow pump to operate until all foreign matter has been

flushed from the pipes.

It is recommended that the gar

den hose be used to supply water continuously to the

tank during this cleaning period.

6. Turn off pump. Make pipe connection to chiller inlet.

7.

Refill the chiller tank with tap water and remove

garden hose.

8.

Start pump and, while water is circulating, check for

leaks throughout the chilled water system.

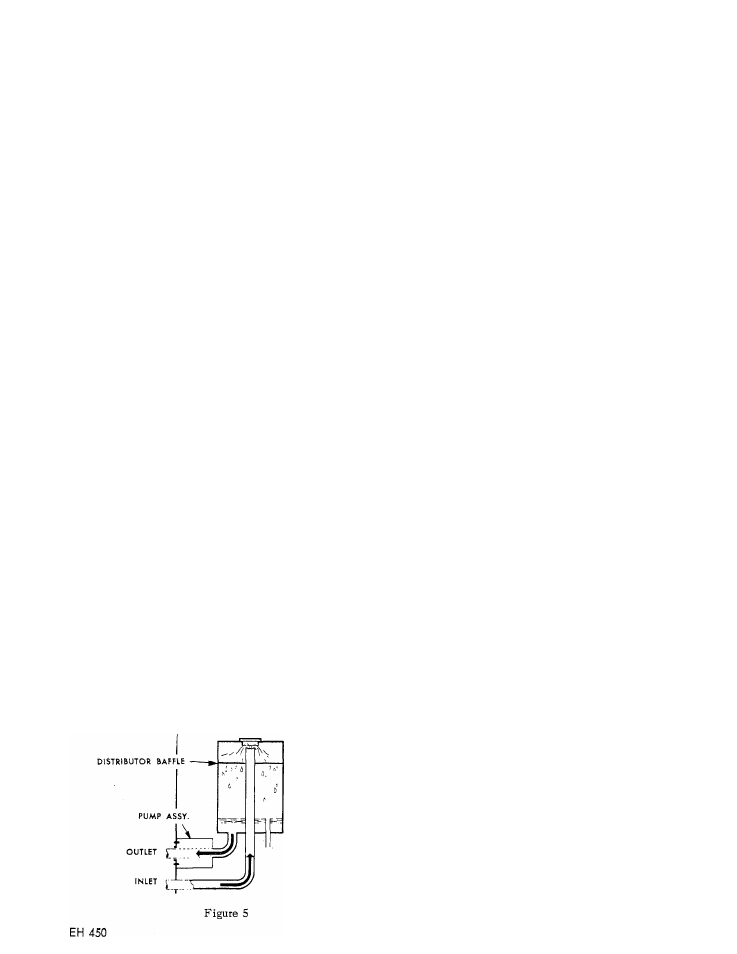

9. Adjust the water level in the chiller while the pump

is still running. This is accomplished by removing the

water level pipe cap as shown in Figure 5. When water

ceases to drain, the level is properly adjusted. Replace

the drain cap. Turn off the pump. (If no water flows

when the drain cap is removed, refill the tank and repeat

the draining operation to adjust the water level).

10.

Add chilled water additive (packed in chiller tank).

The

package

supplied

is

sufficient

for

chilled

water

systems

containing

up

to

20

gallons

of

water.

For

systems

larger

than

20

gallon

capacity,

add

one-half

(1/2) package for each additional 10 gallon capacity or

fraction thereof. (Consult Bryant distributor for estimat

ing chilled water circuit capacities).

11. Replace the lid on the chiller tank.

12. Replace the condenser fan belt. Adjust tension.

13. The system is now ready to operate.

OPERATING LEVEL

DRAIN

1.

Be sure the condenser fan guard has been installed

properly.

2.

Be sure main manual gas valve is off. Light pilot as

described on instruction plate.

3.

Set thermostat to “Cool”; set thermostat fan switch

to “Auto”; and set thermostat below room temperature.

4. Turn on main electric switch to unit.

5.

Observe condenser fan operation; adjust belt tension

if necessary.

6.

Check indoor fan operation by turning thermostat fan

switch

to

“on”

for

continuous

fan

operation.

Move

thermostat above room temperature and observe that the

indoor fan remains on.

7.

To place the system in operation, open the main

manual gas valve, replace the front panel (all panels),

and set the thermostat at the desired temperature.

High Temperature Cut-Out. The high temperature circuit

includes

a

high

temperature

control

located

on

right

side of generator plus a high temperature relay (lockout

relay) located in control box. If the generator becomes

overheated the contacts in the high temp control open,

causing the high temp relay to go into lockout position.

The

gas

valve

closes,

the

fans

and

pump

stop,

and

they will not recycle until the lockout relay is reset.

To reset lockout relay turn electric power off and then

back on. Be sure to locate and correct cause for high

temp cut-out.

VII. ADJUST GAS INPUT

Gas input should agree with that shown on the rating

plate of the unit. The burners are equipped with fixed

orifices intended to give the correct gas input with a

manifold pressure of 2.6" w.c., using 1030 BTU natural

gas of 0.63 S. G. Before lighting burners, inspect to be

sure that they have not become dislodged or cocked

during shipment and installation.

To measure gas input, proceed as follows:

1. Adjust primary air if necessary.

2. Measure the- gas input at the meter. Be sure all

other gas appliances are turned off. Input at the

burner's

may

be

increased

or

decreased

slightly

by

adjustment

of

the

regulator

in

the

burner

supply line.

Caution:

Prolonged operation of the unit should not be

attempted with the front panel off. The unit may be ran

for short periods with the panel removed.

- 7 -