Cutting crown molding – Black & Decker 81/4" COMPUND MITER SAW 9425 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

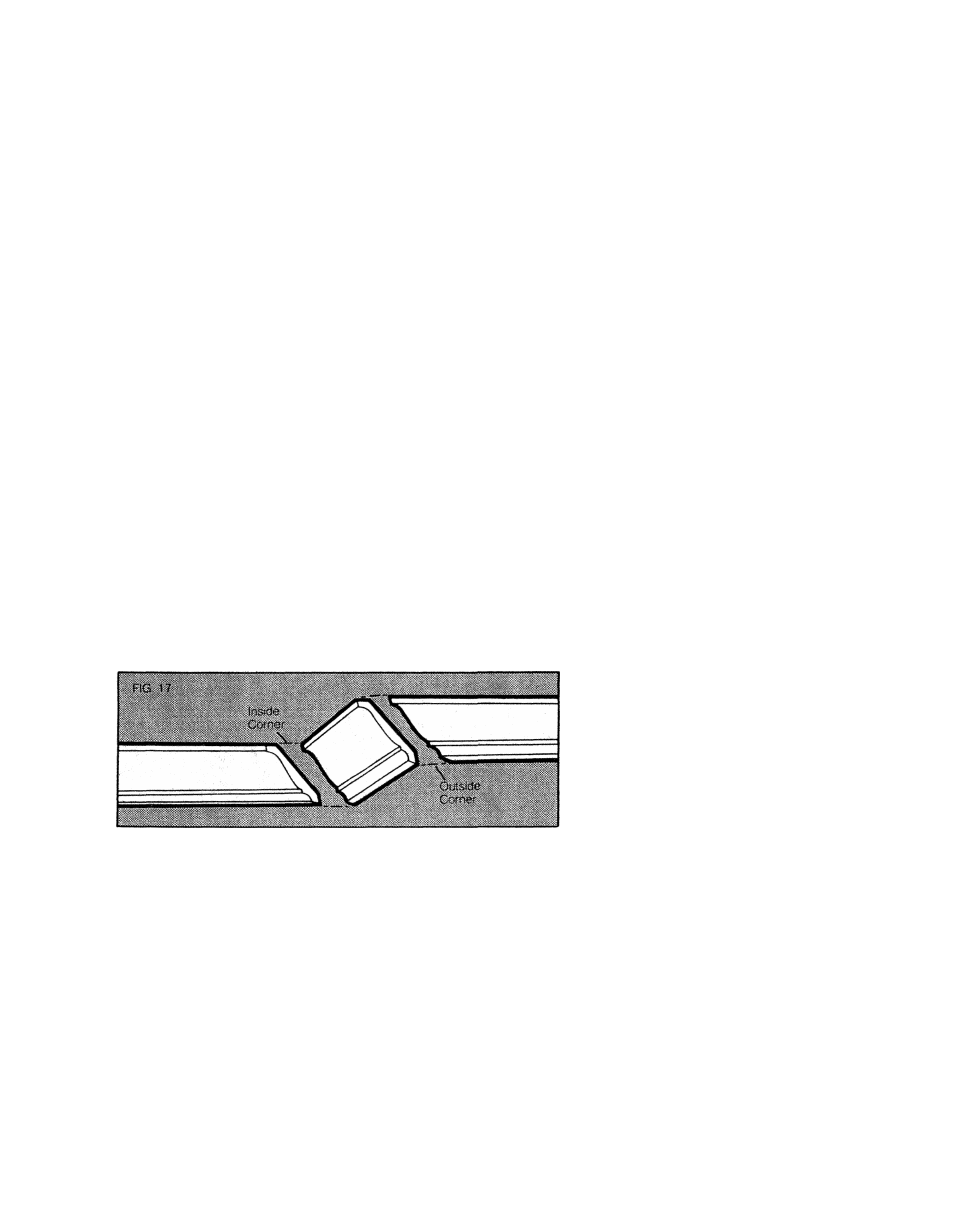

Cutting Crown Molding

Your Compound Miter Saw is probably better suited to the difficult task of cut

ting crown molding than any other tool made. In order to fit properly, crown mold

ing must be compound mitered with extreme accuracy (see Figure 17).

The two surfaces on a piece of crown molding that fit flat against the ceiling

and the wail of a room are at angles that, when added together, equal exactly 90"^.

Most crown molding has a top rear angle (the section that fits flat against the ceil

ing) of 52° and a bottom rear angle that fits flat against the wail of 38°.

In order to accurately cut crown molding for a 90° inside or outside comer,

refer to the chart that follows.

FOR ALL CUTS:

1. Molding laying with broad back surface down flat on saw table

2. The settings below are for All Standard (U.S.) crown molding with 52° and 38°

angles.

BEVEL POST

SETTING

TYPE OF CUT

33.85°

LEFT SIDE, INSIDE CORNER;

1. Top of molding against fence

2. Miter table set right 31.62°

3. Save left end of cut

33.85°

RIGHT SIDE. INSIDE CORNER:

1. Bottom of molding against fence

2. Miter table set left 31.62°

3. Save left end of cut

33.85°

LEFT SIDE, OUTSIDE CORNER:

1. Bottom of molding against fence

2. Miter table set left 31.62°

3. Save right side of cut ______

33.85°

RIGHT SIDE. OUTSIDE CORNER:

1. Top of molding against fence

2. Miter table set right 31.62°

3. Save right side of cut

When setting bevel post and miter table angles for all compound miters,

remember that:

1. The settings are interdependent so that changing one changes the other as

well, and

2. The angles presented for crown moldings are very precise and difficult to set

exactly. Since they can easily shift slightly and very few rooms have exactly

square corners, ail settings should be tested on scrap molding.

PRETESTING WITH SCRAP MATERIAL (S EXTREMELY IMPORTANT!