Cont’d) – Briggs & Stratton 243434 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

(cont’d)

©

©

©

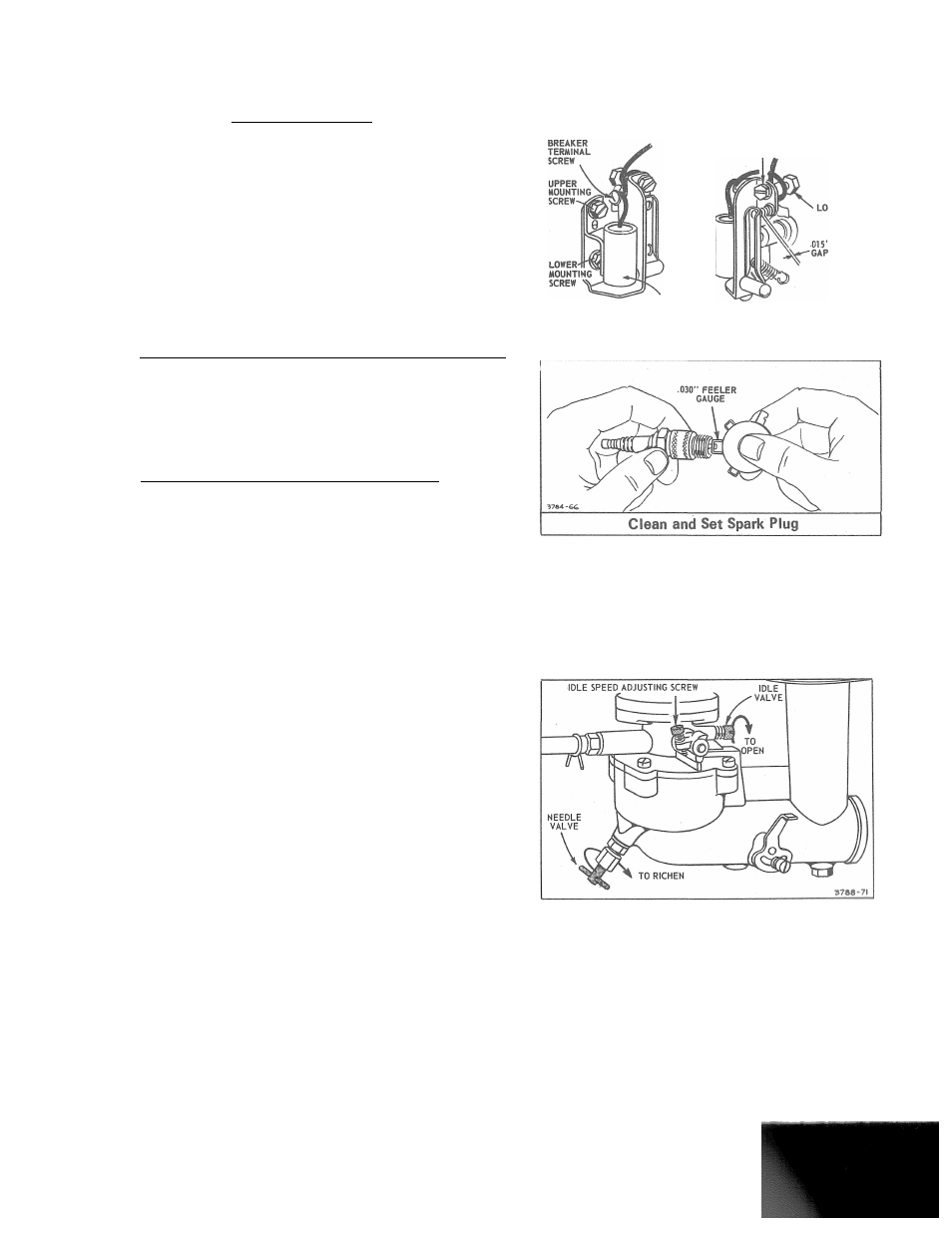

CLEAN AND ADJUST CONTACT POINTS

Remove cover. Clean points with a carborundum con

tact point stone. Then insert a hard finished card or

piece of paper and close and open points. The paper

will absorb any dirt or filings on the points. Adjust

breaker points as follows:

a. Rotate crankshaft until points open to widest gap,

b. Loosen lock_ nut illustrated o e s o w until it is just

snug.

c.

Rotate breaker point screw to obtain .020" gap.

d. When gap is .020" tighten locknut.

e. Replace breaker box cover.

CLEAN SPARK PLUG — Clean and reset gap at .030*

every 100 hours of operation.

CAUTION: Blast cleaning of spark plugs In machines

that use abrasive grit is not recommended. Spark plugs

should be cleaned by scraping or wire brushing and

washing with a commercial solvent or gasoline.

DRAIN

FUEL TANK AND CLEAN FUEL FILTER

Loosen thumb screw below filter bowl. Remove and

clean filter bowl and screen. Open shut-off valve to

see If fuel flows freely from the tank.' IMPORTANT: If

you find a gummy, varnish-like substance use alcohol

or acetone to dissolve it.

TURN BREAKER POINT

SCREW

CLOCKWISE TO INCREASE GAP

CONDENSER

Clean and Adjust Contact Points

Section

,

4

,

A

S

CAiiUiETOi ADJUSTMENTS

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

and load.

Initial Adjustment

Turn needle valve c l o c k w i s e until it just closes, —

CAUTION:

Valve may be damaged by turning It in

too far.

Now open needle valve 1-1/2 turns counterclockwise.

Close idle valve In same manner and open It 1 /2to3/4

turns. This initial adjustment will permit the engine

to be started and warmed up prior to final adjustment.

Final Adjustment

Turn needle valve in until engine misses (lean mixture), then turn it out past

smooth operating

point until engine runs unevenly (rich mixture). Now turn needle valve to the mid-point totwstn rich iid itin

so the engine runs smoothly. Hold throttle at idle position, set Idle speed adjusting screw until fist iilt is

obtained (1200 RPM). Hold throttle in idle position and turn Idle valve in (lean) and out (rich) until tififit idles

smoothly. Then reset idle speed so that engine Idles at 1200 RPM. Release throttle — enqiiit ilcild icctltritt

without hesitation or sputtering. If engine does not accelerate properly, re-adjyst

1

»-. a siif|iitlf

richer mixture.