Maintenance – Briggs & Stratton 243434 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Sectiofs

3

MAINTENANCE

©

©

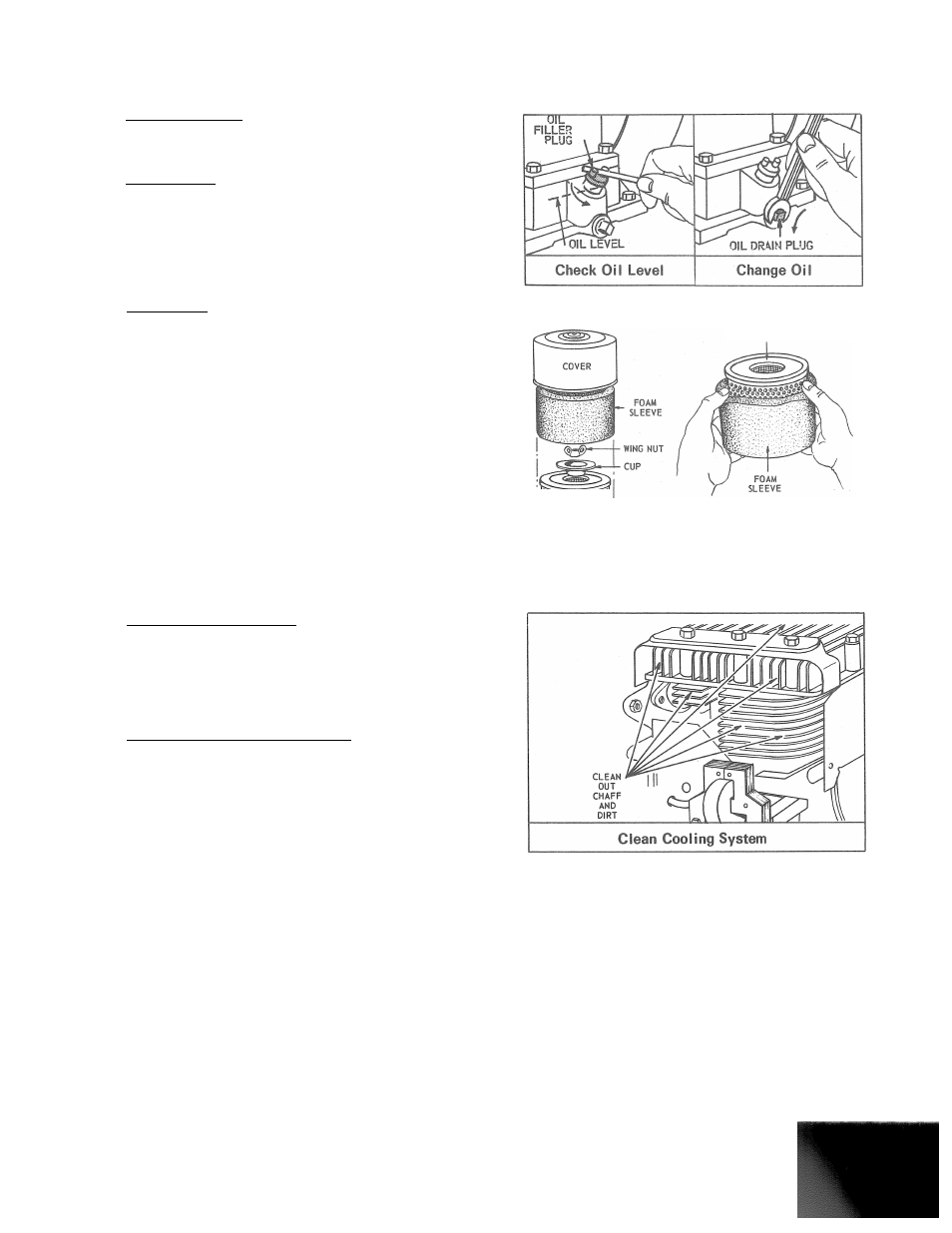

CHECK OIL LEVEL

Check before starting and after every 5 hours of opera

tion.

BE SURE OIL LEVEL IS MAINTAINED.

CHAWOE OIL fCrankcasel

Change oil after first 5 hours of operation. Thereafter

change oil every 25 hours of operation. Remove the oil

drain plug. Drain oil while engine is warm. Remove

oil filler cap or plug and refill with new oil. Replace

oil filler cap or plug. Add oil regularly after each 5

hours of operation.

SEiViCINe НЕДVf PUT? AIR CLEANEi

Clean and re-oil foam pre>cleaner at 3 month intervals

or every 25 hours, whichever occurs first.

1. Remove wing nut and cover.

2» Remove foam pre-cleaner element by sliding it up

off of the paper cartridge,

3. A — lash foam in liquid detergent and water»

В ~ Squeeze dry.

C — Oil with one ounce engine oil. Squeeze to dis

tribute oil evenly.

4. Assemble to paper cartridge. Reassemble cover and

wing nut. Screw wing nut down tight

Yearly or every 100 hours, whichever occurs first, re

move paper cartridge. Clean by tapping gently on flat

surface. If very dirty, replace cartridge, or wash in

liquid detergent and water. Rinse until water remains

clear. Cartridge must be air dried thoroughly before

using.

NOTE: Service more often under dusty conditions.

CLEAN

COOLING SYSTEM

Grass or chaff may clog cooling system after prolong

ed service

in

cutting dry grasses or hay. Continued

operation with a clogged cooling system causes se

vere overheating and possible engine damage. Remove

blower housing

and

clean regularly.

CLEAN

COMBUSTION CHAMBER

every

100-300 hours

of operation. If the engine operates at constant speed

and at relatively constant load, the use of regular au

tomotive fuels results in

a

gradual build-up of lead

deposits in the combustion chamber.

This causes the engine to lose power and prevents the

valves from seating properly. Removing the deposits

is easy and will pay big dividends in reliability and

increased valve life.

1. Remove cylinder head screws.

2.

Turn crankshaft until piston is at top of cylinder

bore and both valves are closed. Scrape and wire

brush the lead and carbon deposits from cylinder

head and combustion chamber.

3.

Re-use cylinder head gasket only if in good condi

tion. Replace cylinder head. Turn each screw in

with wrench

until screw head is lightly seated.

4.

Use socket

wrench with 6 inch handle and turn all

screws 1/4

turn. Tighten screws in sequence

illus

trated.

Run engine approximately 5 minutes and re-

ticjlireo all screws approximately 1/4 turn.

------- WING NUT

DRY

TYP€

FILTER

' DRY TYPE

I l°rPooSfS¿So°¿o°°¿ T~ Pit TFP

filter

Clean Air

Cleaner

4

A S

8

F i i i i l © :

■ i U s T

!"i'