Bryant Model 378 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Determine gas input as follows:

a.

Determine the number of seconds required for

the gas meter test dial to complete one revo

lution.

b. Divide 3600 by the nuniber of seconds in

Item (a) above.

c.

Multiply result of Item (b) by the number of

cubic feet shown for one revolution of the

test dial. This gives you cubic feet per hour

of gas flow.

d.

Multiply result of Item (c) by the heating

value of the gas in BTU (consult local util

ity for value). This gives you the total meas

ured input in BTUH. Compare this value with

that on your rating plate.

Example: Suppose that the size of the test dial is

1/2 (.5) cu. ft.; it takes 20 seconds for the dial to

complete one revolution; heating value of gas is

1050 BTU/cu. ft. Proceed as follows:

a.

20 seconds to complete one revolution.

b. 3600 divided by 20 equals 180.

c.

180 X 0.5 equals 90 cu. ft. per hour of gas

flow.

d.

90 X 1050 equals 94,500 BTUH input.

Only minor changes should have to be made at the

pressure regulator. If the manifold pressure must be

changed more than ±.3 w.c. to obtain rated input,

the orifices should be changed accordingly.

4. Air Flow and Temperature Rise

The furnace is approved for operation under the

temperature rise conditions shown in Table I.

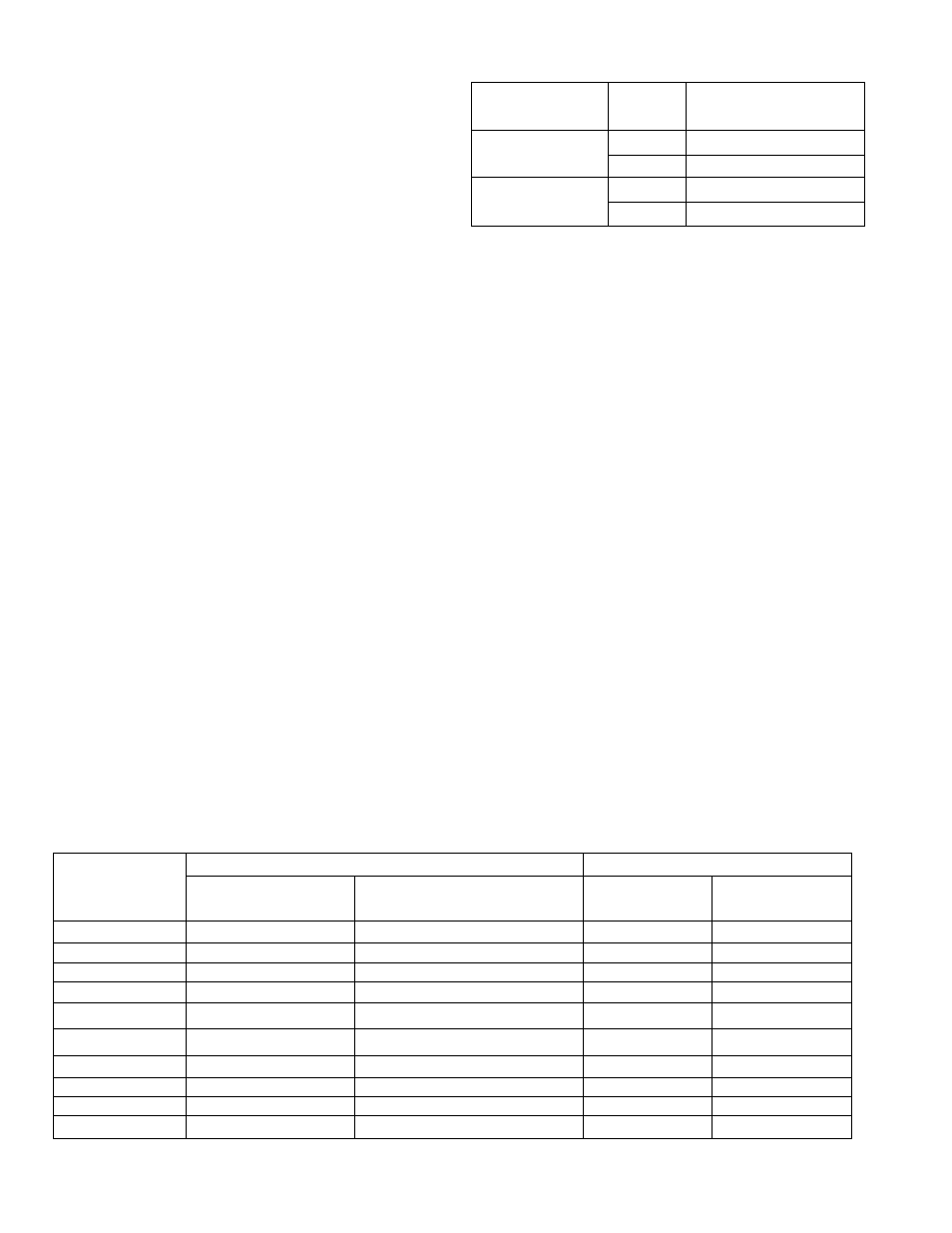

TABLE

Model No.

Input Btu

per hr.

Temperature Rise Air

through Furnace

36W, 54W, 48R,

60R,&l50-378

150,000

45 ° F to 75 ° F

100,000

20 ° F to 75 ° F

90W, 108W, 90R

120R, 8s300-378

300,000

45 ° F to 75 ° F

200,000

20 ° F to 75 ° F

The pulley setting has been made at the factory to

give an air flow compatible with the intended use of

the equipment; i. e., the setting varies with the

type of cooling coil to be used. Table II gives the

pulley setting as the furnace leaves the factory,

and shows also how the pulley can be adjusted to

give the desired air flow if the duct resistance is

higher than normal.

The static pressure against which the furnace is

operating is the difference in pressures in the

return air duct and the discharge duct hear the

furnace. If this differential pressure, determined

when the filters are clean and the pulley is opened

the number of turns shown for normal static, is more

than shown for normal static in Table II, the blower

speed should be increased by changing the pulley

setting to that shown in the column for higher than

normal static pressures.

The temperature rise is the difference between the

temperature of the air in the return duct and in the

discharge duct near the furnace. This temperature

rise, measured after equilibrium has been attained,

should be within the range shown in Table I. The

pulley setting shown in Table II should give an air

rise within the approved range.

TABLE II

Model

Normal Static (ARI)

High er Static *

No.

Static

Factory Setting of

Static

Pulley Setting

in. w.c.

Pulley Turns Open

in. w.c.

Turns Open

36W - 378

0.15

31/2

0.50

1V2

54W - 378

0.20

4

0.50

2

48R - 378

0.20

IV

2

0.40

0

60R - 378

0.20

3

V

2

0.50

IV

2

150 - 378

0.20

21/2

0.50

V2

90W - 378

0.25

11/2

0.45

0

108W - 378

0.30

21/2

0.50

1

90R - 378

0.25

ya

0.35

0

120R - 378

0.30

1

0.40

0

300 - 378

0.25

V

2

0.35

0

* The furnaces are approved for operation up to 0.50 in. w.c.

EH 378

. 6 -