Extension cords, Operation – Black & Decker 5027 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Extension Cords

Double-insulated tools have 2

wire cords, and can be used with 2

wire or 3 wire extension cords. Only

round jacketed extension cords

should be used. If the extension will

be used outside, the cord must be

suitable for outdoor use. Any cord

marked as outdoor can also be used

for indoor work. (The letters “WA” on

the cord jacket indicate that the cord

is suitable for outdoor use.)

An extension cord must have

adequate wire size (AWG or

Amercian Wire Gauge) for safety,

and to prevent loss of power and

overheating. The smaller the gauge

number of the wire, the greater the

capacity of the cable, that is 14

gauge has more capacity than 16

gauge. When using more than one

extension to make up the total

length, be sure each individual

extension contains at least the mini

mum wire size.

To determine the minimum wire

size required, refer to the chart

below:

Before using an extension cord,

inspect it for loose or exposed wires,

damaged insulation, and defective

fittings. Make any needed repairs or

replace the cord if necessary. Black

& Decker has extension cords

available that are CSA Certified for

outdoor use.

CHART FOR MINIMUM WIRE SIZE (AWG) OF EXTENSION CORDS

NAMEPLATE

TOTAL EXTENSION CORD LENGTH-FEET

RATING-AMPS

25

50

75

100

125

150

175

200

0-10.0

18

18

16

16

14

14

12

12

10.1 - 13.0

16

16

14

14

14

12

12

12

13.1 - 15.0

14

14

12

12

12

12

12

—

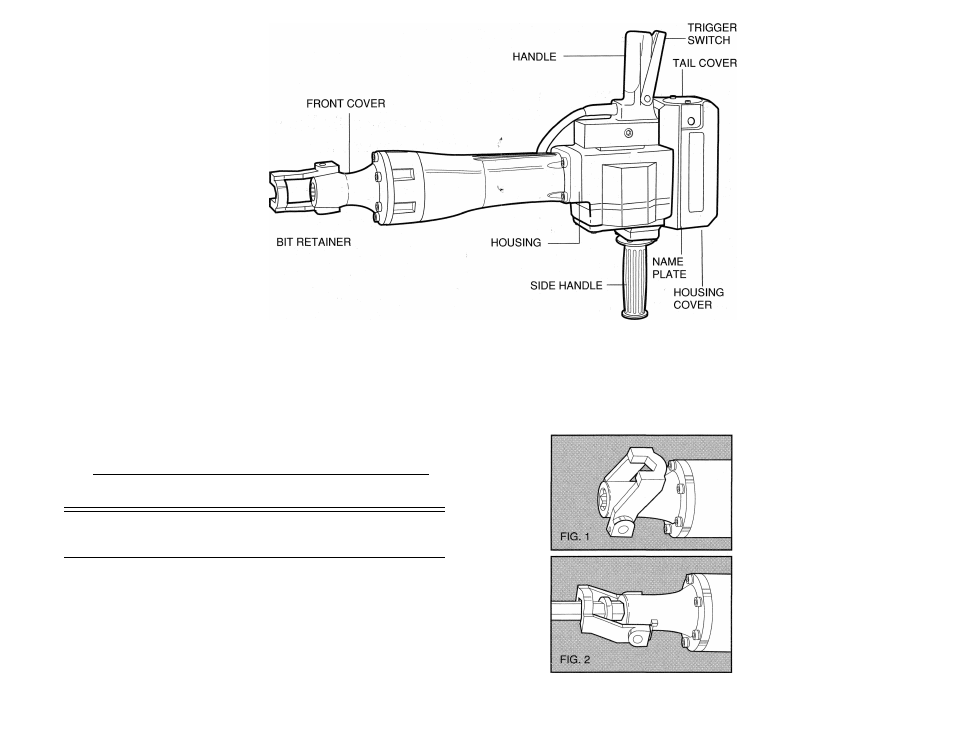

INSTALLING THE BIT

1. With the bit retainer directed

backward, insert the bit shank

into the hole in the front cover.

(Fig.1)

2. Swing the bit retainer back into

place so that it engages the bit

shank and prevents bit from

coming all the way out of front

cover. (Fig. 2)

NOTE: Use a mallet to open/

close the retainer. When removing

the bit, follow the above procedure in

reverse order.

Operation

(ALWAYS WEAR EYE PROTECTION)

Before turning the tool on,

locate the tip of the demolition bit as

desired. Rest the weight of the too!

on the bit and turn the hammer on.

Let the tool’s weight work to your

advantage; this will be easier and

more efficient. Pushing on the tool

only reduces efficiency.

Guide the tool, turning it off

whenever changing locations in

order to locate the bit at the desired

spot.

1. Squeeze the trigger switch after

applying the tip of the bit to the

crushing position. In some

cases, it is necessary to punch

the tip of the bit against the

crushing position forcibly in

order to begin the striking

stroke. This is not due to

malfunction of the tool. It means

that the safe guard mechanism

against no-load striking is

working.

2. Operate the tool by utilizing its

own weight. The performance

will not be better even if the tool

is pressed or thrust forcibly

against the work surface. Hold

the tool with a force just

sufficient to counteract the

reaction. CAUTION: Sometimes

the tool does not begin the

striking stroke even when the

motor rotates because the oil

has become thick. If the tool is

used at low temperatures or if it

is not used for a long time, the

tool should be run at no load for

five minutes in order to warm it

up.