Grease replacement, Mamtenance and inspection, Important – Black & Decker 5027 User Manual

Page 5: Precautions on using your pavement breaker, Double insulation, Applications, Prior to operation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Grease Replacement

The air tight construction of your

hammer prevents most grease

leakage so that the tool can be used

for a long time without the need for

grease replacement. About every 6

months you should clean out the

grease and add a fresh supply.

Mamtenance and

Inspection

CAUTION:

Be sure to switch

power OFF and disconnect the plug

during maintenance and inspection.

INSPECTING THE BIT

Since use of a dull bit will

degrade efficiency and cause

possible motor malfunction, sharpen

or replace the bit as soon as dulling

is noted.

INSPECTING THE MOUNTING

SCREWS

Regularly inspect all mounting

screws and ensure that they are

properly tightened. Should any of the

screws be loose, retighten them

immediately. Failure to do so could

result in serious hazard.

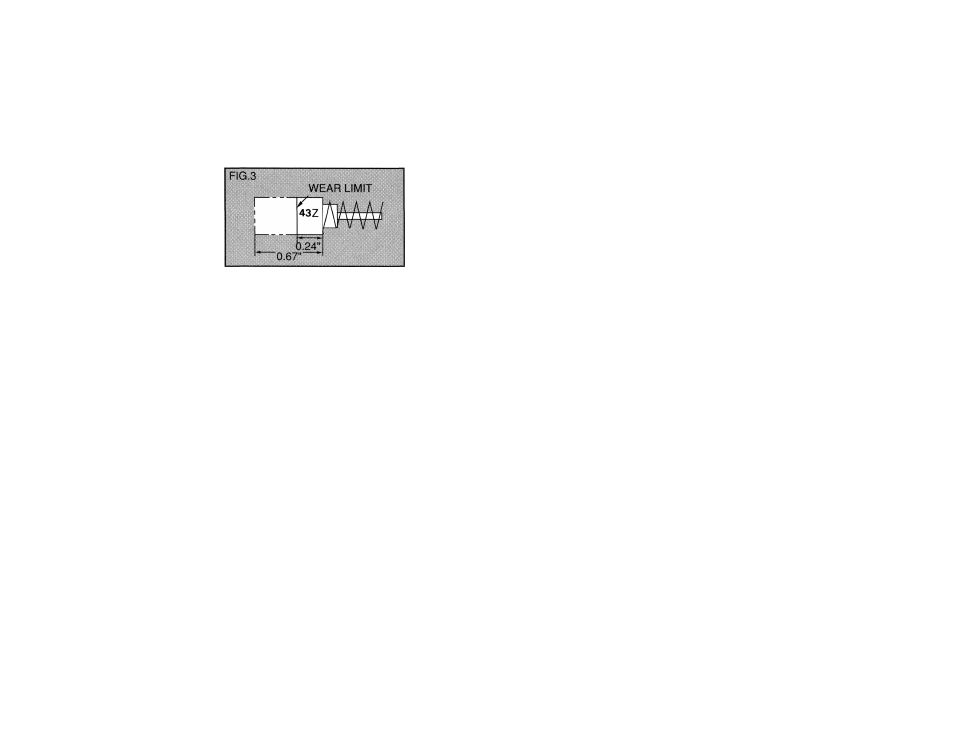

INSPECTING THE CARBON

BRUSHES (FIG. 3)

The motor employs carbon

brushes which are consumable

parts. When they become worn to or

near “wear limit”, it could result in

motor trouble. When an auto-stop

carbon brush is used, the motor will

stop automatically when the brushes

are worn out. At that time, replace

both carbon brushes with new ones.

In addition, always keep carbon

brushes clean and ensure that they

slide freely within the brush holders.

REPLACEMENT PROCEDURE

Loosen the screw (Flexagon

socket hd. bolt M5 x 10) of the tail

cover, then remove the tail cover.

(Center spread) After removing the

brush cap, the carbon brush can be

removed. After replacing the carbon

brush, tighten the brush cap, then

mount the tail cover securely and

tighten the screws.

Important

TO assure product SAFETY and

RELIABILITY,repairs, maintenance

and adjustment (excluding brush

inspection and replacement) should

be performed by Black & Decker

Service Centers or other qualified

organizations, always using Black &

Decker replacement parts. When

servicing Double Insulated Tools,

USE ONLY IDENTICAL REPLACE

MENT PARTS.

Precautions On Using

Your Pavement

Breaker

1. Always wear a face mask when

operating this tool.

2. Use earplugs when operating

for extended periods.

3. Be sure to lock the bit holder in

position.

4. The bit becomes extremely hot

during operation. Avoid touching

it without heavy gloves.

5. Check all screws for tightness

before operation.

6. When working at elevated

locations, be alert to objects and

persons below.

7. Wear steel toed shoes to

protect your feet from injury.

Double Insulation

DOUBLE-INSULATED tools are

constructed throughout with TWO

separate “layers” of electrical

insulation or one DOUBLE thickness

of Insulation between you and the

tool’s electrical system.

Tools built with this insulation

system are not intended to be

grounded. As a result, your tool Is

equipped with a two-prong plug

which permits you to use extension

cords without concern for maintain

ing a ground connection.

NOTE: DOUBLE INSULATION

does not take the place of normal

safety precautions when operating

this tool. The insulation system is for

added protection against injury

resulting from a possible electrical

insulation failure within the tool.

CAUTION: When servicing all

tools, USE ONLY IDENTICAL RE

PLACEMENT PARTS. Repair or

replace damaged cords.

Applications

Breaking concrete, chipping off

concrete, grooving, and driving piles

Prior To Operation

POWER SOURCE

Ensure that the power source to

be utilized conforms to the power

requirements specified on the

product nameplate.

POWER SWITCH

Ensure that the power switch is in

the OFF position. If the plug is con

nected to a power receptacle while

the power switch is in the ON

position, the tool will start operating

immediately, inviting serious

accident.