Installing the guide bar and safety chain (con't), Operating, Before starting – Poulan 4400 User Manual

Page 4: Fuel and oil, Caution, A word about chain oiling, Instructions

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLING THE GUIDE BAR AND SAFETY CHAIN (con't)

Figure 4

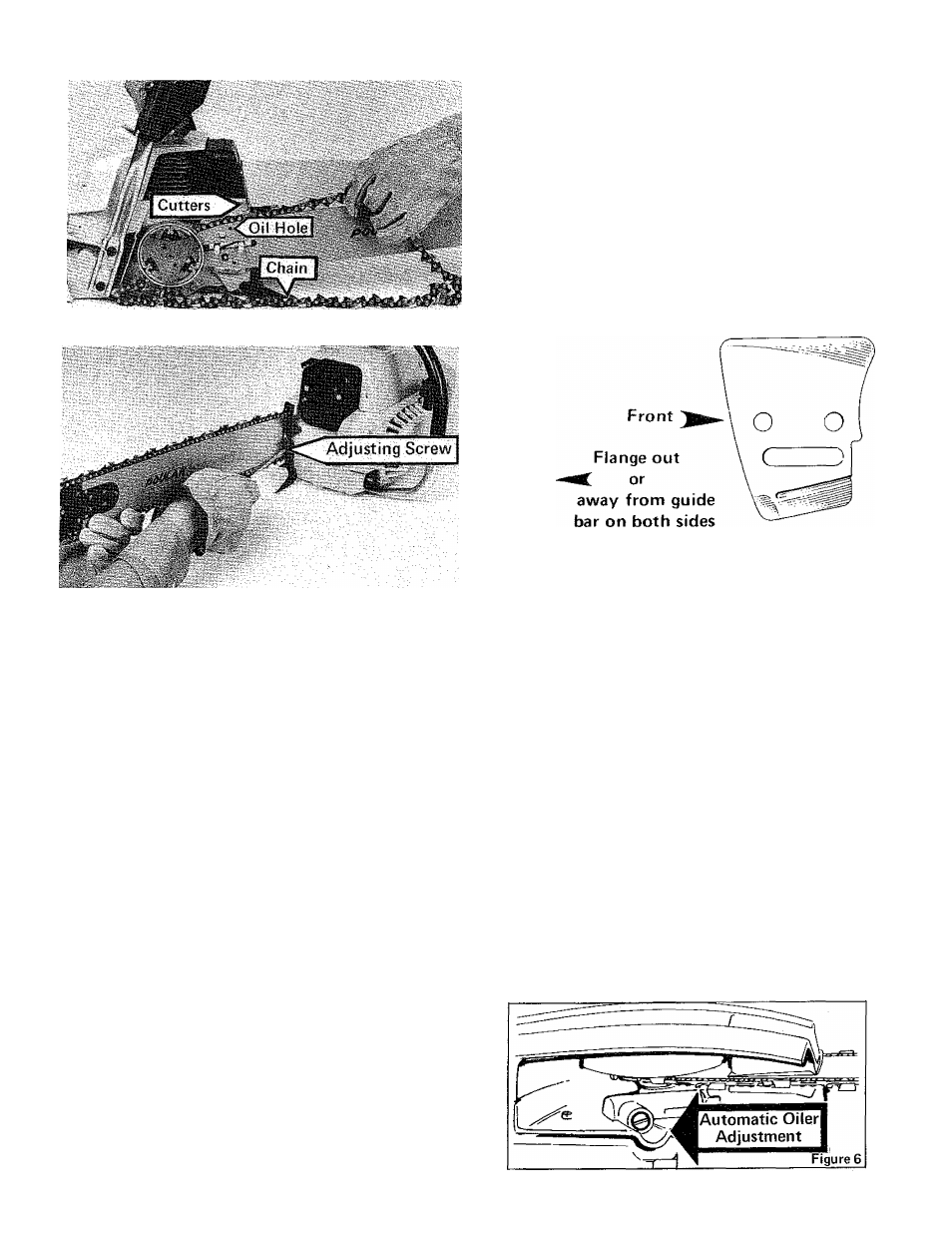

4. Place the chain over the sprocket and engage the drive link

tangs between the sprocket teeth. (Note the direction of

the chain teeth.) Starting at the top of the bar, gradually

work the chain into the groove of the bar until all the drive

links are engaged in the bar groove. FIGURE 4.

5. Replace the outer guide bar plate and bar clamp. Replace

the bar mounting nuts and tighten finger tight,

6. Holding the tip of the bar up, adjust the chain tension by

turning the bar adjusting screw clockwise. FIGURE 5.

7. When the chain is properly tensioned it will move freely but

not sag below the bar. Now tighten the bar mounting nuts

completely.

CHAIN STRETCHES WHEN USED. CHECK THE TENSION

OFTEN!

Figure 5

OPERATING

Before Starting

O Check the chain tension. Is the chain sharp?

O Are the handles clean of gas and oil?

O Did you fill the fuel AND oil tanks?

FUEL and OIL

Fuel Mix: 16 parts gasoline to 1 part oil {8 oz. Poulan 16:1 oil

to one gallon gasoline). (Or use Poulan 32:1 oil—2 gallons

gasoline to 8 oz. oil).

CAUTION;

When preparing fuel mixture, mix only the amount needed for

the job you are to do. Do not use fuel mixture that has been

stored longer than two (2) months. Fuel mixture stored longer

than this will cause hard starting and poor performance of

your saw. If fuel mix has been stored in your saw longer than

this time it should also be removed and filled with a fresh

mixture before using.

BAR AND CHAIN OIL: Use straight bar and chain lube above

30 Fahrenheit. If bar and chain lube is not available use a

good grade SAE 30 oil. Between 30 F and 0 F use a mixture

of 95% bar and chain lube and 5% either kerosene or# 1 diesel

fuel. For below 0 F operation increase the kerosene or diesel

fuel to 10%.

A WORD ABOUT CHAIN OILING

1. Fill the oil tank each time you fill the fuel tank. Lack of oil

on the chain will quickly ruin the bar and chain.

2. You will use at least 1/2 tank of oil for each tank of gas. If

you use less, check for a plugged oil hole in the guide bar.

Use clean oil. Do not let sawdust or dirt into the oil tank.

INSTRUCTIONS

Clean the oil cap and the area around it before removing.

Oil on the bar and chain will drip off after use. Let the saw

stand and cool off. Wipe the bottom clean before storing.

AUTOMATIC OILER: Your Poulan Chain Saw is equipped

with an automatic oiler which delivers a constant flow of oil to

the bar and chain whenever the engine is running. The

automatic oiler has an adjustment screw, to regulate the flow

of oil, located at the bottom of the bar clamp for easy access.

Turn this screw counterclockwise Jt to increase the flow,

clockwise

to decrease the flow. (See Figure 6) it is

possible to run out of chain oil before running out of fuel

when operating the saw at high RPM for a long period of time,

such as when pruning and debranching. The automatic oiler

may deliver more oil than required for this type of cutting. If

there is no chain oil in the oil tank when the saw runs out of

fuel, make the following adjustment: Turn the adjustment

screw clockwise ^ X until it stops. Then turn the screw

counterclockwise

%turn. REMINDER — RE-ADJUST

FLOW RATE WHEN RETURNING TO CUTTING THAT

REQUIRES MORE CHAIN LUBRICATION, SUCH AS FELL

ING AND BUCKING.