Lubrication, Maintenance – MTD 216-031-000 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Never make unnecessary adjustments. The fac

tory recommended settings are correct foi most

applications.

If adjustments are needed, refer to the engine

manual packed with the tiller.

LUBRICATION

Chain Case

The chain case is pre-lubricated and sealed at the

factory. It requires no checking unless the chain

case is disassembled. To fill with grease, lay the

right half of the chain case on its side, /^dd 10

ounces of Plastilube #0 grease and assemtie the

left half to the right half. The grease can ae ob

tained at your nearest authorized dealer lis ed on

the back of this manual. Order part no. 737 0133.

MAINTENANCE

A,

I WARNING {

Disconnect the spark plug wire from

spark plug and ground against the

engine block (secure in “V” slot)

before performing any maintenance.

See figure 8.

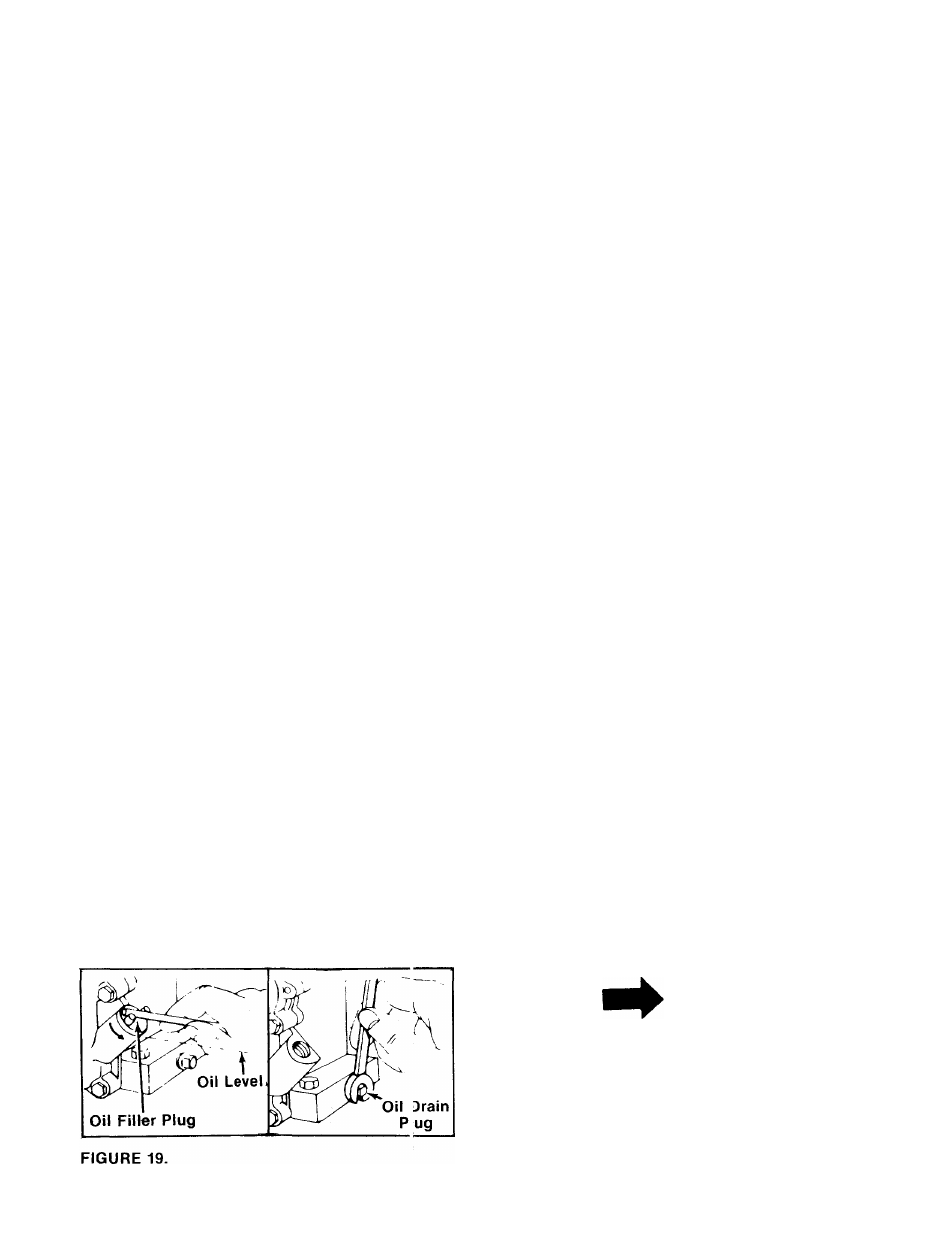

Change the oil in the crankcase after the first two

hours of operation of your new engine and after

each 25 hours of use thereafter. This will ensure

proper lubrication of internal parts to prevent ex

cessive wear.

To change the oil, remove drain plug and tip the

tiller forward while engine is warm. See figure 19.

Replace drain plug. Remove oil filler cap, taking

care to remove dirt around filler plug. Refill with

new oil of proper grade. Replace filler cap.

AIR CLEANER

Service the air cleaner every 25 hours of operation.

The air cleaner prevents damaging dirt, dust, etc.

from entering the carburetor and being forced into

the engine. It is important to engine life and per

formance.

To service air cleaner, refer to the engine manual

packed with the tiller.

Never run your engine without air cleaner com

pletely assembled.

SPARK PLUG

The spark plug should be cleaned and the gap

reset at least once a season or when oil is

changed. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specifica

tion.

CLEAN ENGINE

Wipe off all spilled fuel and oil. Keep the engine

clean of foreign matter and be sure the cDoling

fins on the cylinder are kept clean to permit Droper

air circulation. This is an air cooled engire and

free flow of air is essential to proper engire per

formance and life.

ENGINE OIL

Check oil level before each use. Be sure oil Isvel is

maintained full to point of overflowing. See figure

19.

BELT REPLACEMENT

1. Remove belt cover assembly by removing one

hex nut and lock washer, one self-tapping

screw, one hex bolt, flat washer and hex nut

and one hex bolt and external lock washer.

See figure 20.

2. Lift the belt cover assembly off the tiller. Be

careful not to bend or kink the clutch cable.

See figure 20.

3. Remove the belt and position the new belt on

engine pulley and chain case pulley.

NOTE

Upon reassembly of belt cover,

place the belt over top of the idler

pulley and between engine pulley

and weld pin on belt cover assembly.

See figure 20.

4.

Fasten belt cover assembly in position.

Secure with the hardware removed in step 1.

10