Engine maintenance, Engine lubrication, Engine air filter – Troy-Bilt 12159 User Manual

Page 17: Carburetor adjustment, Warning, Maintenance/service

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE/SERVICE

ENGINE MAINTENANCE

Engine Lubrication

The engine on your equipment is a two-cycle (“two-

stroke”) engine. Lubrication is provided by mixing the

proper type and amount of two-cycle oil with unleaded

regular gasoline. See Page 9 for mixing instructions.

Attempting to operate the engine on gasoline alone

(without the appropriate amount of two-cycle oil mixed

in) will cause the engine to overheat and seize up.

Engine Air Filter

It is extremely important that air filter service be per

formed by the maintenance schedule and according to

the steps that follow. Your equipment has two thin

flocked filters and a thick foam filter. See Figure 17.

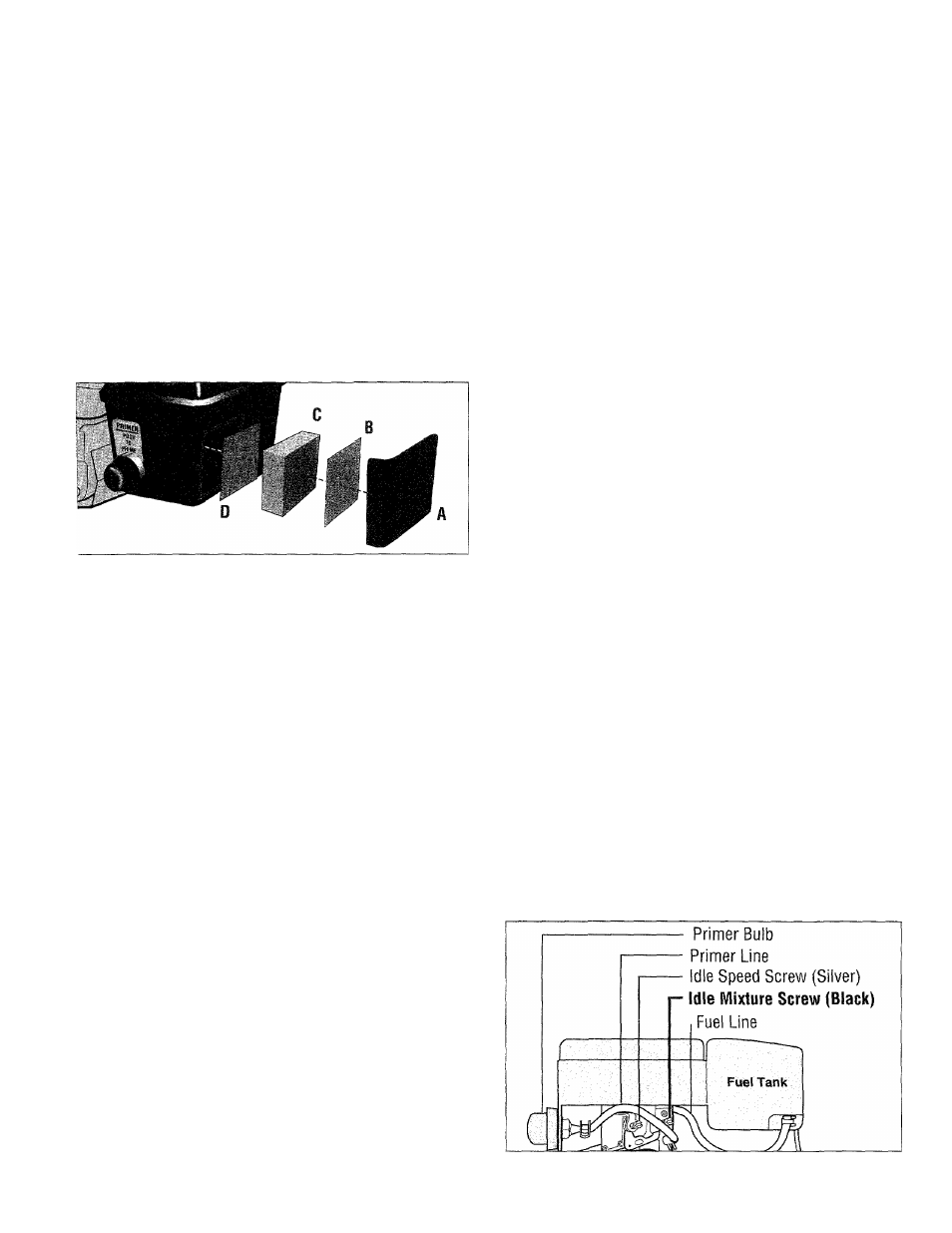

■igure 17: Engine air filter assembly. Cover (A); larger

locked filter (B); foam filter (C); smaller flocked filter (D).

IMPORTANT: Never run engine without air filter as-

iembly properly installed on engine.

'b

Remove and Inspect the Air Filter Components:

Loosen both cover screws.

Remove the cover along with the screws.

Remove the outer, larger flocked filter.

Remove the thick foam filter.

Remove the inner, smaller flocked filter.

Inspect all three filters for discoloration or dirt accumu-

ition. If either is present, service the filters.

Thoroughly clean inside of cover and body.

b

Service the Air Filters:

hick Foam Filter Service-

Clean

and re-oil every three (3) months or every 25

Derating hours. Clean and re-oil daily if used in ex-

9mely dusty conditions.

Wash in water and detergent solution and squeeze

lon’t twist) until all dirt is removed.

Rinse thoroughly in clear water.

Wrap in a clean cloth and squeeze until dry.

Saturate with motor oil and squeeze (don’t twist) to

stribute oil and remove excess oil.

7/n Flocked Filters Service-

Wash both flocked filters in a water and detergent mix.

Rinse thoroughly in clear water, then air dry the filters.

Reassemble filter components as shown in Figure 17.

Carburetor Adjustment

WARNING

Do not tamper with the engine governor screw

which is factory-set for the proper engine speed.

Overspeeding the engine beyond the factory high

speed setting can be dangerous and wiii void the

engine warranty. Authorized service shaii be

sought if a problem exists.

^ WARNING

The temperature of the muffler and adjacent engine

areas may exceed 150°F (65° C). Contact may

cause burns. Avoid these areas. Remove the

spark plug lead and ground the lead to the engine

to prevent accidental starts and fires.

Failure to do this could cause personal injury.

If the engine is running poorly or has low power under

tilling conditions, an idle mixture screw adjustment to the

carburetor may solve the problem. However, first in

spect and service the spark plug and the air filter before

making a carburetor adjustment. If the engine continues

to run poorly (and the fuel mixture is fresh), proceed to

the carburetor adjustment instructions below.

This factory-engineered instruction has been designed to

provide continued optimum engine operating perfor

mance after the engine break-in period, which is approxi

mately 5 to 10 hours. The adjustment, when properly

performed as described below, will not void the engine

warranty. A common screwdriver is needed. If you pre

fer, see an authorized Engine Dealer for adjustment.

Prior to Carburetor Adjustment:

•

Let the engine cool for 30 minutes before continuing.

• From the operator’s position behind the handlebars, lay

the machine down on its left side (muffler side).

Carburetor Adjustment:

•

Locate the carburetor idle mixture screw (see Figure

17A). It is directly under the air filter and is black. Do

Not Adjust The Silver-Colored Screw.

• Turn the idle mixture screw 1/16 of a turn clockwise.

• Return the Tiller/Cultivator to its normal upright operat

ing position and reconnect the spark plug lead.

If the engine continues to run poorly, please contact an

authorized Engine Dealer.

Figure 17A: Idle Mixture Screw can be adjusted.

17