Lubrication, Maintenance, Trouble shooting – MTD 030 thru 062 User Manual

Page 12: Cuning blaoe

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altii ude and

load. Refer to the separate engine manual packed /vith your

mower for carburetor adjustment information.

NOTE:

A dirty air cleaner will cause an engine to n 'n rough.

Be certain air cleaner is clean and attached to the c 3rburetor

before adjusting carburetor.

If the blade is secured to the blade adapter with two bolts,

remove the two small bolts, lock washers and nuts which

hold the blade to the adapter.

A

WARNING: Periodically Inspect the blade

adapter for cracks, especially if you strike a

foreign object. Replace when necessary.

LUBRICATION

A

WARNING: Always stop engine and dii connect

spark plug wire before cleaning, lubricating or

doing any kind of work on lawn mowei.

Blade Control—Lubricate the pivot points on the b ade con

trol handle and the brake cable at least once a se. ison with

light oil. See figure 15.The blade control must operate freely

in both directions.

Blade Control

Handle

Pivot Brake

Point Cable

FIGURE 15.

Chute Deflector—The torsion spring and pivot po nt should

be lubricated periodically with light oil to prevent a ly rust or

binding. Deflector must work freely.

Wheels—The wheels require no lubrication. Howe/er, if the

wheels are removed for any reason, lubricate the surface of

the axle bolt and the inner surface of the wheel wit i light oil.

Engine oil may also be used.

Engine—Follow engine manual for lubrication instr jctions.

MAINTENANCE

When sharpening the blade, follow the original angle of grind

as a guide. It is extremely important that each cutting edge

receives an equal amount of grinding to prevent an

unbalanced blade. An unbalanced blade will cause exces

sive vibration when rotating at high speeds, may cause dam

age to the mower and could break, causing personal injury.

The blade can be tested by balancing it on a round shaft

screwdriver. Remove metal from the heavy side until it bal

ances evenly. It is recommended that the blade always be

removed from the adapter for the best test of balance.

Before reassembling the blade and the blade adapter to the

unit, lubricate the engine crankshaft and the inner surface of

the blade adapter with light oil (or engine oil). Lubricating the

bolt holes, bolts and inner surface of the nuts is also recom

mended.

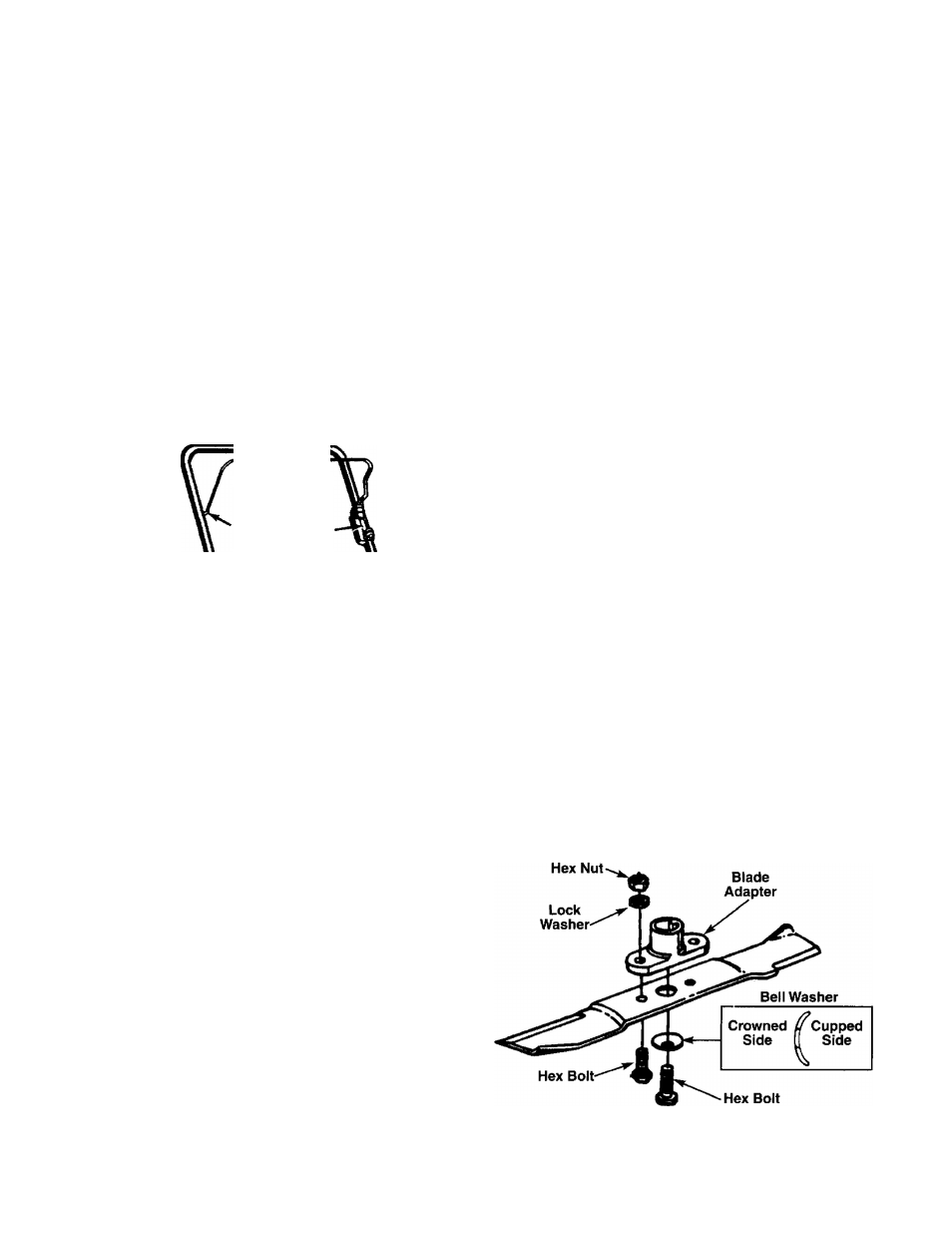

THREE BOLT BLADE MOUNTING

Install the blade to the blade adapter with the side of the

blade marked “bottom” (or with part number) facing away

from the adapter. Refer to figure 16. insert two hex bolts up

through the blade and adapter and secure with lock washers

and hex nuts. Tighten according to “Blade Mounting Torque”

section below.

Place the blade and blade adapter assembly on the engine

crankshaft.

NOTE:

If the adapter is keyed, make sure the key in the

adapter is aligned with the key slot on the crankshaft.

A

WARNING: Be sure to disconnect anc ground

the spark plug wire before perfornring any

repairs or maintenance.

NOTE:

When tipping the unit, empty the fuel tank and keep

engine spark plug side up.

TROUBLE SHOOTING

Refer to page 13 of this manual for trouble shootinji informa

tion.

CUniNG BLAOE

When removing the cutting blade for sharpening o ■ replace

ment, protect hands by using heavy gloves or a rail to grasp

the cutting blade. Remove the bolt and blade supp )rt or bell

washer which hold the blade and adapter to the engine

crankshaft. Remove the blade and adapter from t le crank

shaft.

FIGURE 16.—Three Bolt Blade Mounting

12