Lubrication and maintenance (continued), Auger gear case – Ariens SNO-THRO 937 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Lubrication and Maintenance (Continued)

When replacing belts, replace both belts at same

time. To replace drive belts, disconnect extension

spring and relieve compression of compression

spring on pivot bracket.

Remove idler pin from idler and bracket then idler

from machine.

Remove two hair pins from bracket pin. Cap screw

from pin plate and pin and plate from unit.

Remove pivot bracket and belts from unit.

Install new belts in reverse order.

NOTE:

Make sure pulleys align. If-alignment is

necessary, loosen pin plate cap screw, align belts

and tighten cap screw.

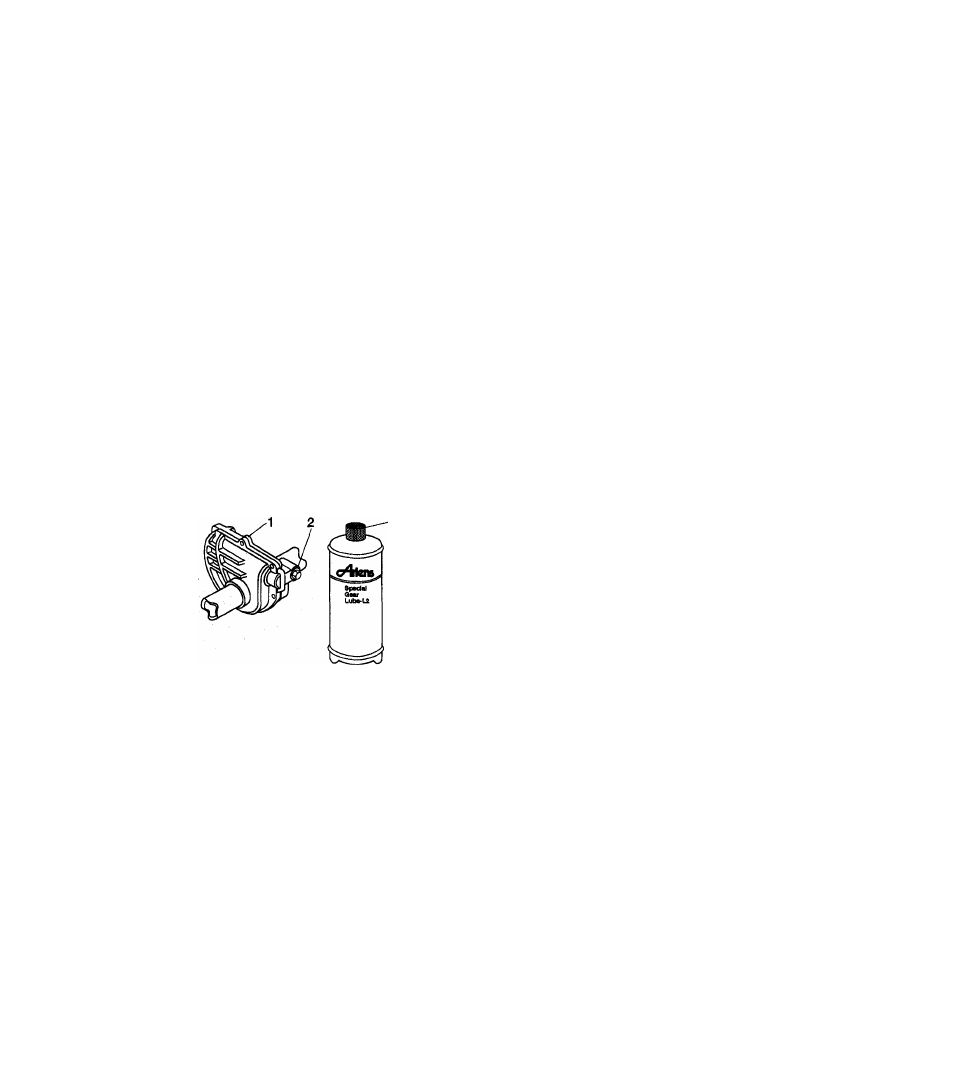

Auger Gear Case

IMPORTANT:

Too much lubricant may cause

excessive leakage. Too little lubricant will cause gear

and/or bearing darhage.

1. Auger Gear Case

2. Gear Lube Fill

3. Ariens Special L-2 Gear Lube

Figures: Auger Gear Case

Gear cases are filled to the correct level at the

factory. Unless there is evidence of leakage, no

additional lubricant should be required. Check for

evidence of leakage every 25 hours of operation.

To insure adequate oil level, (2 oz. mininum), the

following checking procedure is recommended,

especially if there is evidence of leakage. Find a flat

level surface adjacent to a vertical surface (floor next

to wall or post etc). Make a mark on the vertical

surface with marker or tape 10.0 inches up from the

flat level surface. (One inch wide masking or

wrapping tape works especially well).

Remove the gear case oil fill plug. Wipe the inside

end clean with a soft cloth and replace finger tight.

Move the front of the sno thro near the vertical

surface and slowly raise the handlebars until the

mark is seen at the top of the auger/impeller housing.

Count to 100 while holding at the position to insure

that the lubricant has had time to seek a stable level.

Return the sno thro to its level operating position and

remove the gear case oil fill plug to determine if the

end previously wiped clean has been “wetted” by the

lubricant. If so, lubricant level is adequate. Replace

the fill plug.

When adding lubricant, add only Ariens special gear

lube L-2 (Part Number 000080). After adding

lubricant, you may want to check to insure the level is

not too high. To do this, repeat the above procedure

with the mark on the vertical surface one inch higher.

Allow plenty of time to drain at this position with the

fill plug removed. 5 inch high blocks inserted under

the wheels of all models serve well to hold them in a

“drain-to-maximum-level” position.

'A

11