SINGER 192 Spartan User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

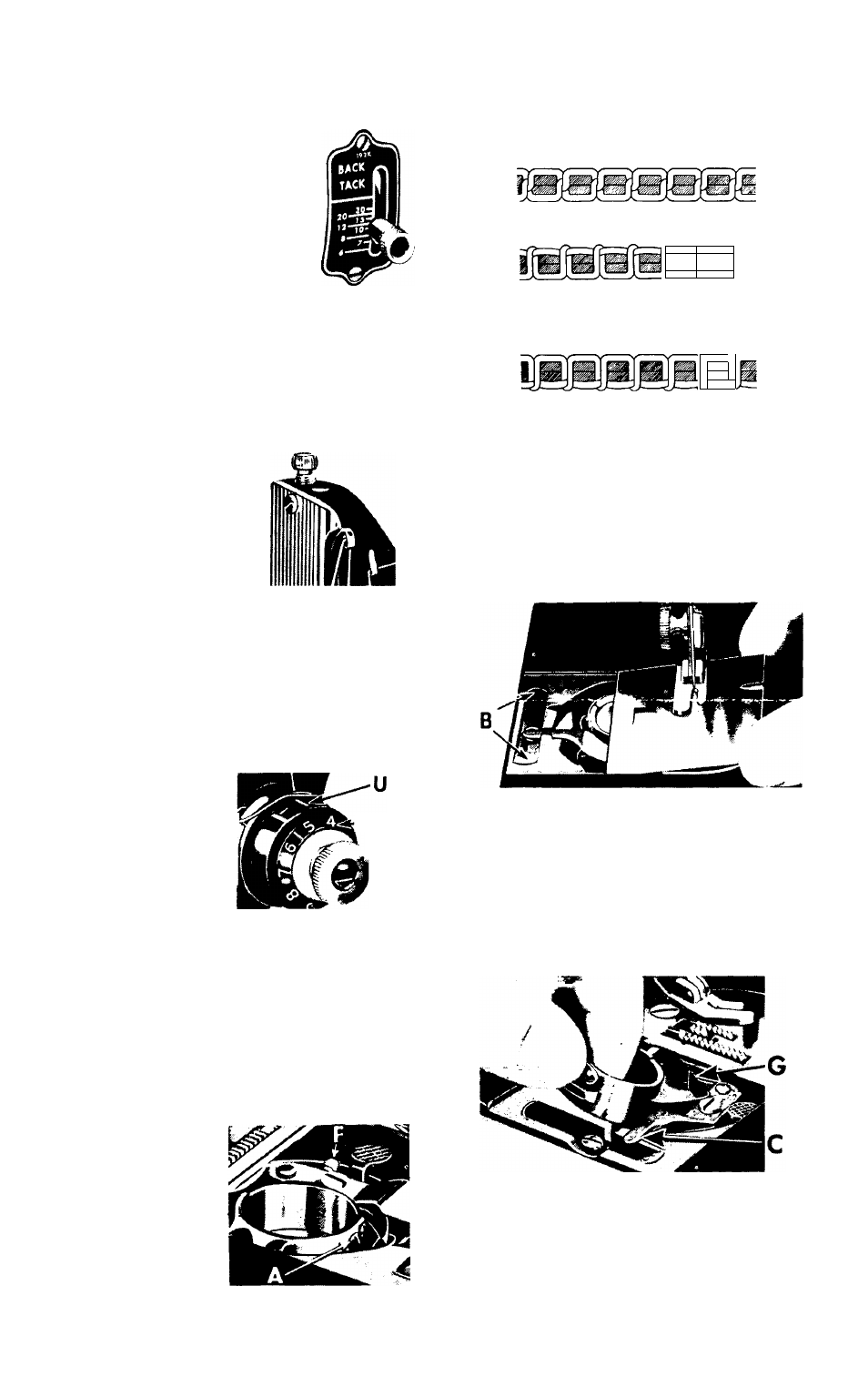

To Regulate Length of Stitch—

Numerals on the indicator

represent

approximate

number of stitches per

inch.

• Turn thumb nut to left.

• Set lever at desired

stitch setting,

• Turn thumb nut to

right until it rests

against

indicator

plate.

F/g. W

To reinforce a seam, raise stitch

indicator lever to its highest posi

tion. The machine will then stitch

in a reverse direction, making it

easy to ’*back tack”

To Regulate Pressure on Presser Foot—

• To d e c r e a s e

pressure,

turn

thumb

screw

up.

• To increase pres

s u r e , t u r n

thumb

screw

down.

F;g. II

For ordinary sewing, pressure of

the presser foot on the material

seldom

requires

changing.

Heavy

materials

require

more

pressure

than

light

materials.

Pressure

should be only heavy enough to

move the work along evenly.

To Regulate Needle Thread Tension —

Numerals on in

dicator

V, Fig,

12, denote dif-

\

__

y

ferent degrees of

tension. When

tension has been

f^W

c o r r e c t l y s e t ,

note number at

l i n e U s o t h a t

this setting may be regained should

the tension be altered for special

work.

• To increase tension, turn thumb

nut

W

to higher number.

• To decrease tension, turn thumb

nut

w

to lower number.

To Regulate Bobbin Thread Tension—

T e n s i o n o n

bobbin

thread

is regulated by

s c r e w

A, F i g .

13, nearest cen

ter of tension

s p r i n g . T u r n

screw

A

over

to right to in

crease

tension;

turn screw to

left to decrease

tension.

A perfectly formed stitch results

when both tensions are balanced so

that the needle and bobbin threads

are drawn equally into the fabric.

Fig. 14. Perfect Sr itching

^ -

"WT^

.

Fig. 15. Iwperject Stitching

Needle thread tension too tight or

Bobbin thread tension too loose.

'Mí

Fig. 16. bnperject Stitching

Bobbin thread tension too tight or

Needle thread tension too loose.

Care and Maintenance of Your

S P A R T A N 1 9 2

When in regular use the machine

should be cleaned periodically.

To Remove and Replace Bobbin Case—

Fig. 17. Slide Plate Removed

Raise needle and presser foot.

Draw slide plate to left.

Remove bobbin from case.

Lift edge of slide plate and draw

it to the right until it is dis

engaged from spring

B.

Fig. n

Fig. 18. Removing Bobbin Case

Lift and move latch

C

to position

shown.

Grasp bobbin case as shown.

Tilt case to left and raise forked

end above bracket

G.

Turn forked end toward you,

then lift out bobbin case.