Maintenance, Electrical / maintenance – Sears 390.304692 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

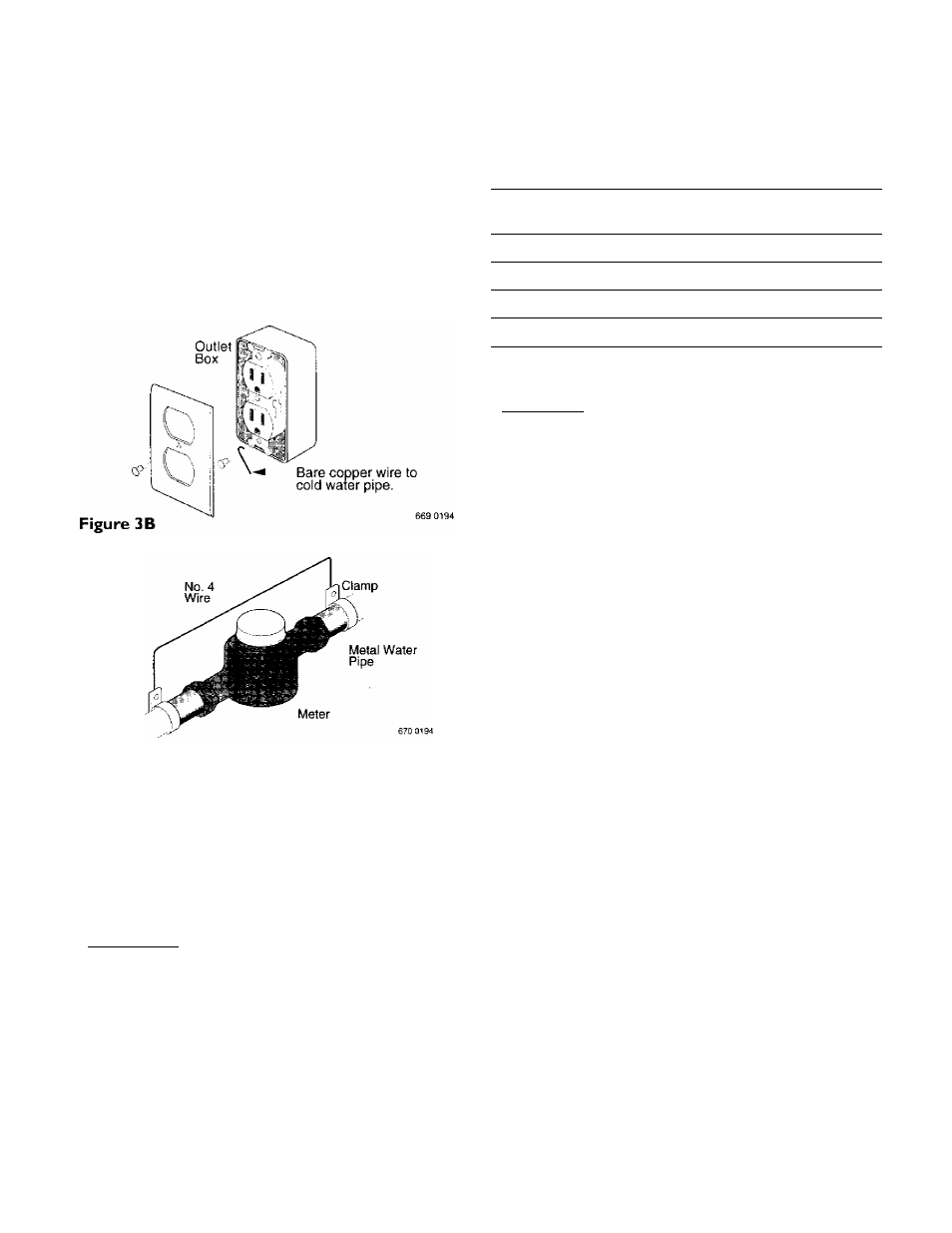

Grounding Outlet

If your outlet is not grounded, install a copper wire, at least

14 gauge (2nim0- from the outlet box, as shown in Figure

3!i, to a metal cold w ater pipe Use ground clamp on pipe.

IMPORTANT: The cold w ater pipe yttii use as a ground

must have metal continuity to electrical ground. If continu

ity is interrupted by plastic, rubber, or other electrical insu-

latttrs; such as hoses, litting,s, washers or gaskets (including

water meter or pump), a metal bypass must be used. Any

electrically insulated connector should be jumped (as shown

in Figure 3C), with ;t length of No.

4

wire clamped securely

at both ends.

ELECTRICAL / MAINTENANCE

Generator Sizing

Figure 3C

Automatic Thermal Overload Protection

This pump motor has a built-in automatic thermal overload

protector. If the motor overheats, the protector will open

and cut off power to the motor before the heat damages it

internally. The overload will reset automatically and the

pump will restart after the pump cools down below the dan

ger point.

A WARNING j)Q NOT attempt to work on the pump or

motor if the overload seems to have tripped. The

motor may restart without warning at any time. You

could be injured and the pump damaged if it starts

when you are working on it.

DO NOT attempt to repair a non-operational sump pump.

Take it to Sears for service by a qualified technician.

Below is the minimum Engine-

must be added to the listed load anti the generator sized ac-

cortlingh’. Cicncnitors are available at all Scars Stores.

Pump

Minimum Watt

Model

HP

Rating of Generator

390.305001

1/2

2800

390.304692

1/3

4500

390.304790

1/3

3400

390.305790

1/2

4200

MAINTENANCE

A CAUTION Make certain that the pump is unplugged

before attempting to service or remove any compo

nent.

1. The motor in the unit is sealed in oil. No additional lubri

cation is necessary.

2. IMPORTANT: Disassembly of the motor assembly will

void the warranty. It might also cause internal leakage and

damage to the unit. If repairs are required, return the

pump to the dealer Ixom whom it was purchased,

3. Inlet screen should be kept clean and free of all foreign

objects.

Pump Cleaning

NOTICE: Attempting to disassemble motor will void the

warranty.

1. Disconnect power cord from electrical outlet before work

ing on pump. Tlie volute bottom may be removed to re

place impeller or clean pump of mud or debris.

2. Remove screws from volute bottom and clean impeller.

Replace the gasket/O-Ring if it is damaged.

To Reassemble:

Attach volute bottom to volute top with screws.