Maintenance, Lubrication – Sears 247-650A User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

-fï-

f . -.'v

.

■

EMlNStON

FIGURE 4. FEEDING MATERIAL INTO GUIDE

EXTENSION

A steady flow of material provides the best

results. Bulky material, such as stalks or heavy

branches, should be fed into the upper guide

extension. See figure 5.

UPPER GUIDE EXTENSION

FIGURE 5. FEEDING MATERIAL INTO UPPER

GUIDE

It is possible to feed too fast and you will find it

will take some experimenting with feeding rates to

get the most out of your shredder without stalling

the engine.

Under certain conditions, it may be necessary to

push the materials into the inlet guide assembly.

When this becomes necessary, use a small

diameter stick—NOT YOUR HANDS. The stick

should be of a size that will be ground up if it gets

into the impeller assembly.

The discharge chute will direct the shredded

material into a pile or a container.

NOTE

Your shredder is equipped with a ny

lon bag with drawstring lock. This

will accommodate a perforated dis

posable plastic bag.

A

CAUTION

Keep clear of the chute area since

the shredded material comes out

with considerable velocity. Always

stop engine and disconnect spark

plug wire when changing bags.

MAINTENANCE

A

____^CAUTION

Always stop engine and disconnect

spark plug wire before doing any

maintenance.

Cutting Blade—The blade may easily be removed

for grinding or replacement as follows:

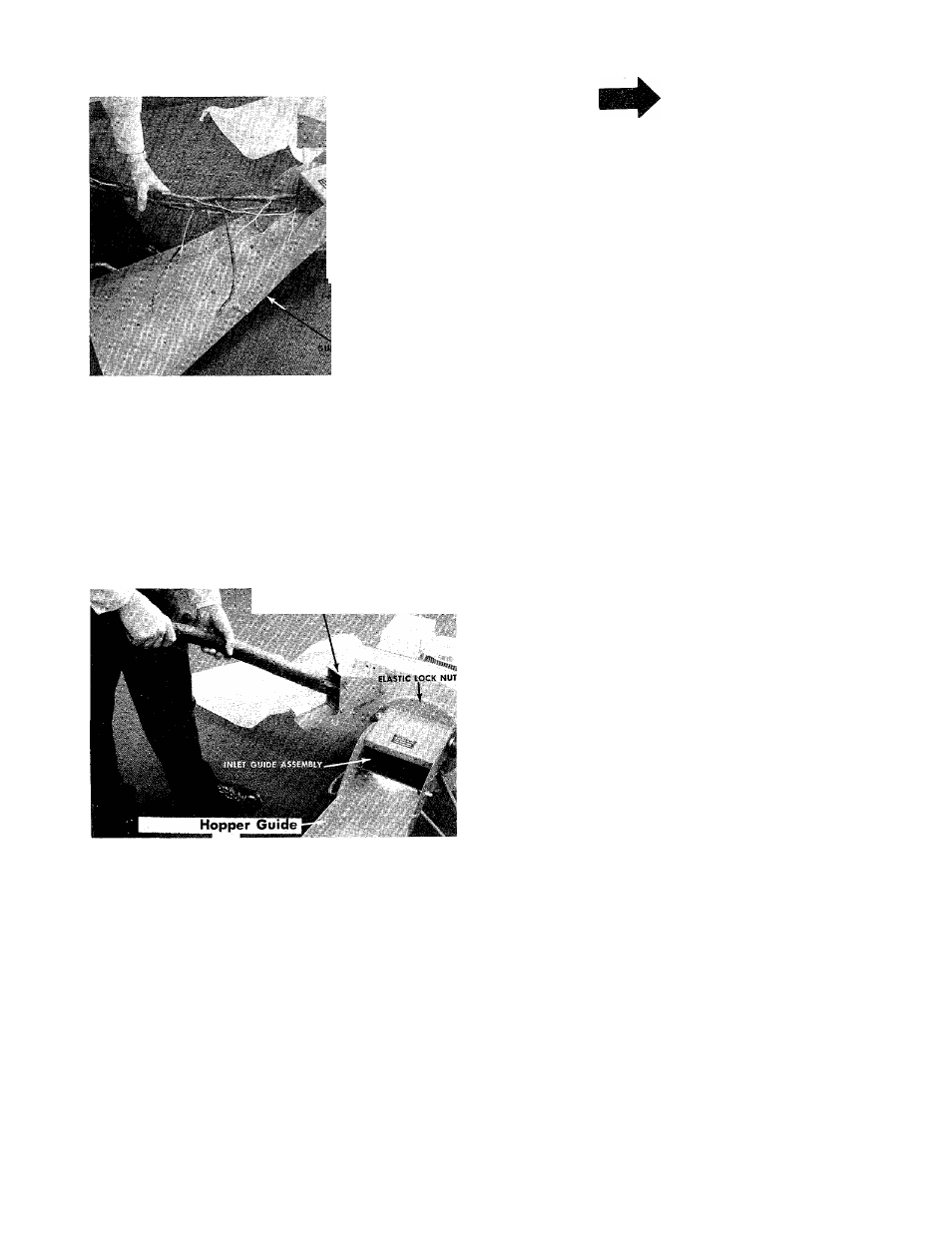

1. Remove guide extension assembly by remov

ing four elastic locknuts (Ref. No. 11). See

page 10.

2. Remove bolt (Ref. No. 38), lockwasher (Ref.

No. 37), flat washer (Ref. No. 36) holding

blade (Ref. No. 45) and blade retainer (Ref.

No. 48) to engine crankshaft. See page 10.

3.

NOTE: Blade is reversible and can be

assembled to crankshaft with either side

showing.

When sharpening blade, follow the original angle

of grind as a guide. It Is extremely important that

each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An

unbalanced blade will cause excessive vibration

when rotating at high speeds and may cause

damage to the unit. Upon reassembly, make

certain all parts are assembled properly and

tightened securely.

LUBRICATION

WHEELS—Wheel bearings are of lifetime Forti-

flex. They require no lubrication.

ENGINE—Follow engine manual for lubrication

instructions.

A>

.CAUTION

Do Not deposit material larger than

1

/

2

” diameter in hopper. This may

cause damage to the shredding

mechanism. Any material heavier

than V

2

” should be fed into the

upperguide extension. (See figure 5.)