Maintenance, Storage, Adjustments – Sears 143.994006 User Manual

Page 5: General, Spark plug, Drain fuel system, Cooling system, Carburetor, Engine speed, Change oil

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

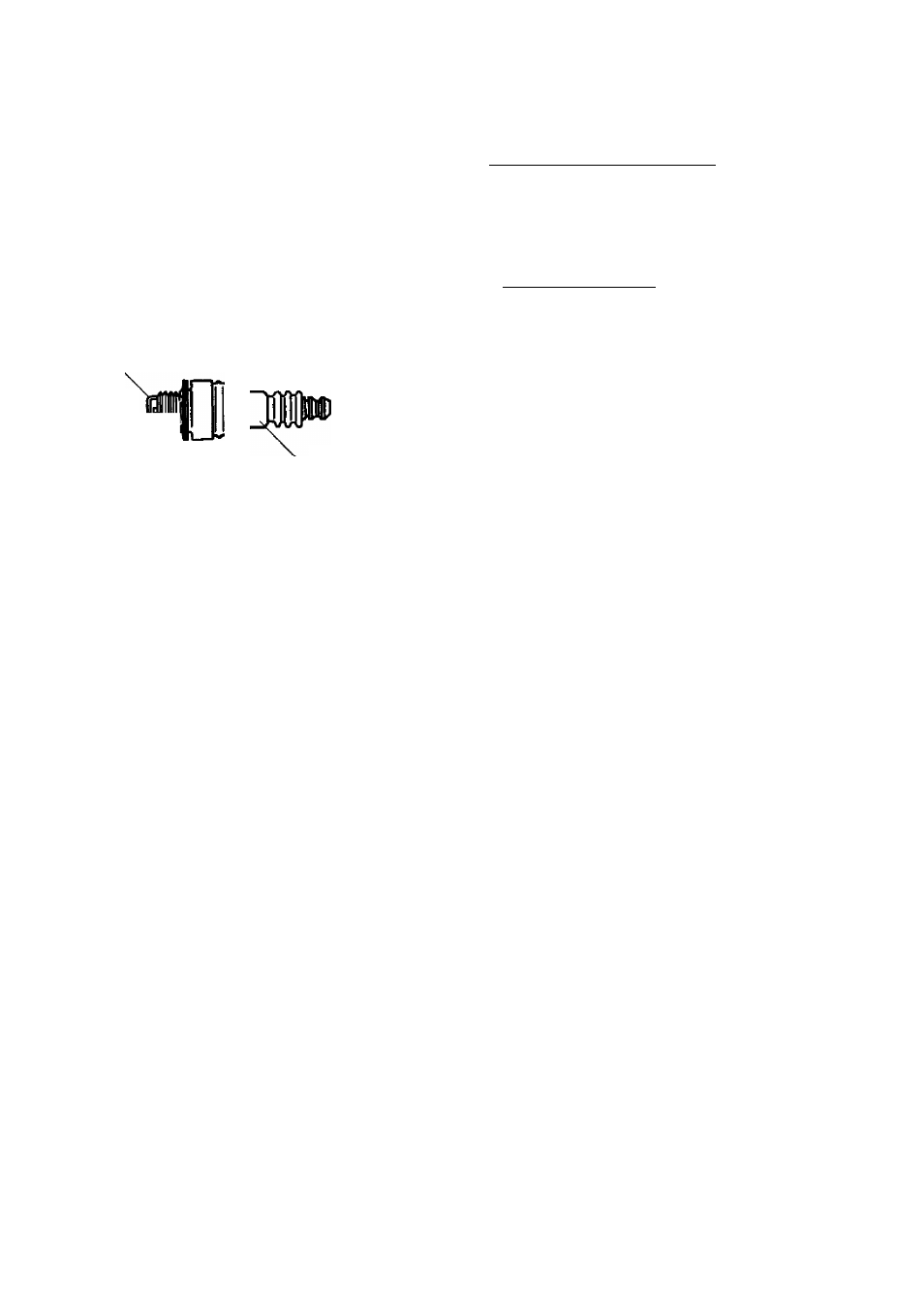

® SPARK PLUG

(see Figure 8):

This spark ignition system meets all requirements of the Cana

dian Interference-Causing Equipment Regulations. This engine

complies with ali current Australian and New Zealand limitations

regarding electromagnetic interference. Check spark plug yearly

or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned or porce

lain is cracked. For replacement use Champion RJ-19LM or

equivalent.

NOTE: A resistor spark plug must be used for replacement.

D. Check electrodes gap with wire feeler gauge and set gap at

.030 if necessary.

. ^

E. Install spark plug, tighten securely.

MAINTENANCE

(Continued)

STORAGE

ELECTRODES

.030 GAP

J

PORCELAIN

CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE NUTS,

BOLTS AND ATTACHMENTS, AND KEEP THESE ITEMS

TIGHTENED.

NEVER TAMPER WITH ENGINE GOVERNOR WHICH IS FAC

TORY SET FOR PROPER ENGINE SPEED. OVERSPEEDING

ENGINE ABOVE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS. CHANGING OF ENGINE-GOVERNED SPEED

WILL VOID ENGINE WARRANTY.

Wl

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR

N ENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL

FUMES MAY REACH AN OPEN FLAME, SPARK OR PILOT

LIGHT AS ON A FURNACE, WATER HEATER, CLOTHES

DRYER OR OTHER GAS APPLIANCE._____________________

IF ENGINE ISTO BE UNUSED FOR 30 DAYS OR MORE, PREPARE

AS FOLLOWS:

© DRAIN FUEL SYSTEM:

A. Remove all gasoline from carburetor and fuel tank to prevent

gum deposits from forming on these parts and causing possi

ble malfunction of engine._____________________________

DRAIN FUEL INTO APPROVED CONTAINER OUTDOORS,

^AWAY FROM OPEN FLAME. BE SURE ENGINE IS COOL.

DO NOT SMOKE.

Figure 8

COOLING SYSTEM:

IMPORTANT: Frequently remove any grass clippings, dirt and

debris from cooling fins, air intake screen and levers and linkage

(see Figure 1). This will help ensure adequate cooling and

correct engine speed.

ADJUSTMENTS

DO NOT MAKE UNNECESSARY ADJUSTMENTS. FACTORY SET

TINGS ARE SATISFACTORY FOR MOST APPLICATIONS AND

CONDITIONS, IF ADJUSTMENTS ARE NEEDED, PROCEED AS

FOLLOWS;

© CARBURETOR

If you think your carburetor needs adjusting, see your nearest

SEARS, ROEBUCK AND CO. (OR SEARS CAtslADA, INC.)

SERVICE CENTER. Engine performance should not be affected

at altitudes up to 7,000 feet. For operation at higher elevations,

contact your nearest SEARS, ROEBUCK AND CO. (OR SEARS

CANADA, INC.) SERVICE CENTER.

© ENGINE SPEED

*

B. Run engine until fuel tank is empty and engine stops due to

lack of fuel.

NOTE:

Fuel stabilizer (such as STA-BIL) is an acceptable

alternative in minimizing the formation of ftjel gum deposits

during storage. Add stabilizer to gasoline in fuel tank or

storage container. Always follow mix ratio found on stabilizer

container. Run engine at least 10 minutes after adding stabi

lizer to allow it to reach carburetor.

© CHANGE OIL:

Change oil if it has not been changed in the last three (3) months.

See “CHANGE OIL" instructions in “MAINTENANCE” section on

Page 3.

© CLEAN ENGINE:

Remove any clippings, dirt, or chaff from exterior of engine.

GENERAL

'Just as your automobile needs professional mechanical mainte

nance from time to time, so does your Craftsman engine. Replace

ment of the spark plug and ai r cleaner is made necessary by NORMAL

use. Professional Air-Cooled Engine Service is as close as your

nearest Sears Roebuck and Co. (or Sears Canada, Inc.) Sen/ice

Center. A yearly check-up or tune-up by Sears is a good idea to avoid

breakdowns or delay... do it at the end of the season, then you' re ready

for the next. We even prepare it for storage for you.

Page 4

181-1178-11