Before starting (continued), Starting, Stopping – Sears 143.996706 User Manual

Page 3: Before starting

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BEFORE STARTING

(Continued)

STARTING

c.

D.

E.

F.

Feed starter rope through starter handle (see Figure 5) and /V

tie a left hand knot, leaving 1/2 inch to 1 inch of starter rope^^

extending beyond left hand knot. DO NOT PU LL LEFT HAN D

KNOT INTO STARTER HANDLE YET.

With starter handle resting on rope guide (see Figure 4),

check starter rope for slack. If there is any slack, pull more

starter rope through starter handle and relocate left hand

knot to eliminate slack.

iV

Untie slip knot at starter.

=

Pull left hand knot into starter handle.

NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED

AREAS.

ENGINE

EXHAUST

CONTAINS

CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS

(CARBON MONOXIDE IS ALSO PRESENT IN ENGINE

EXHAUST FROM LIQUID PETROLEUM (LPG) AND NATURAL

GAS FUEL SYSTEMS).

KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

WARNING - TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150"F (65°C). AVOID THESE AREAS.

CHECK OIL LEVEL:

IMPORTANT: NEVER RUN ENGINE UNLESS OIL LEVEL IS

BETWEEN “FULL” AND “ADD" MARKS ON

DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL FILL PLUG IS TIGHTENED

SECURELY INTO OIL FILL HOLE.

A POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area around oil fill plug (see Figure 1).

C. Remove oil fill plug and dipstick. ''

D. Wipe dipstick clean, insert it into oil fill hole and tighten

securely.

E. Remove oil fill plug and check oil level. If level is not up to

“FULL" mark on dipstick, add recommended oil, until it is.

POUR SLOWLY.

.

Wipe dipstick clean each time oil level is checked.

DO NOT FILL ABOVE “FULL” MARK ON DIPSTICK.

F.

Replace oil fill plug and tighten securely.

See “MAINTENANCE" section for any future oil level and oil

change instructions (see Page 3).

® FILL FUEL TANK

with gasoline as specified in the preceding

“OIL & FUEL RECOMMENDATIONS,” item 2.

NEVER MIX OIL WITH GASOLINE

Never use “stale" gasolinb left over from last season or stored for

long periods.

NEVER FILL FUEL TANKINDOORS. NEVER FILL FUEL TANK

^ WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE WHEN

FILLING FUEL TANK________________________________________

NEVER FILL FUEL TANK COMPLETELY. FILL TANK T01/2”

> BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE FOR

FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM ENGINE

AND EQUIPMENT BEFORE STARTING ENGINE.

ANY LIQUEFIED PETROLEUM (LPG) OR NATURAL GAS FUEL

> SYSTEM MUSTBE LEAKPROOF AND MEET ALL APPUCABLE

CODES AND REGULATIONS.

CHECK THE FOLLOWING:

NOTE: See equipment manufacturer's instructions for control

positions which correspond to engine control positions

in Figure 2._____________

BRAKE CONTROL

CABLE

BOWL DRAIN

SCREW

CARBURETOR

CONTROL KNOB IN

■FASr OR START

POSITION

0

Figure 2

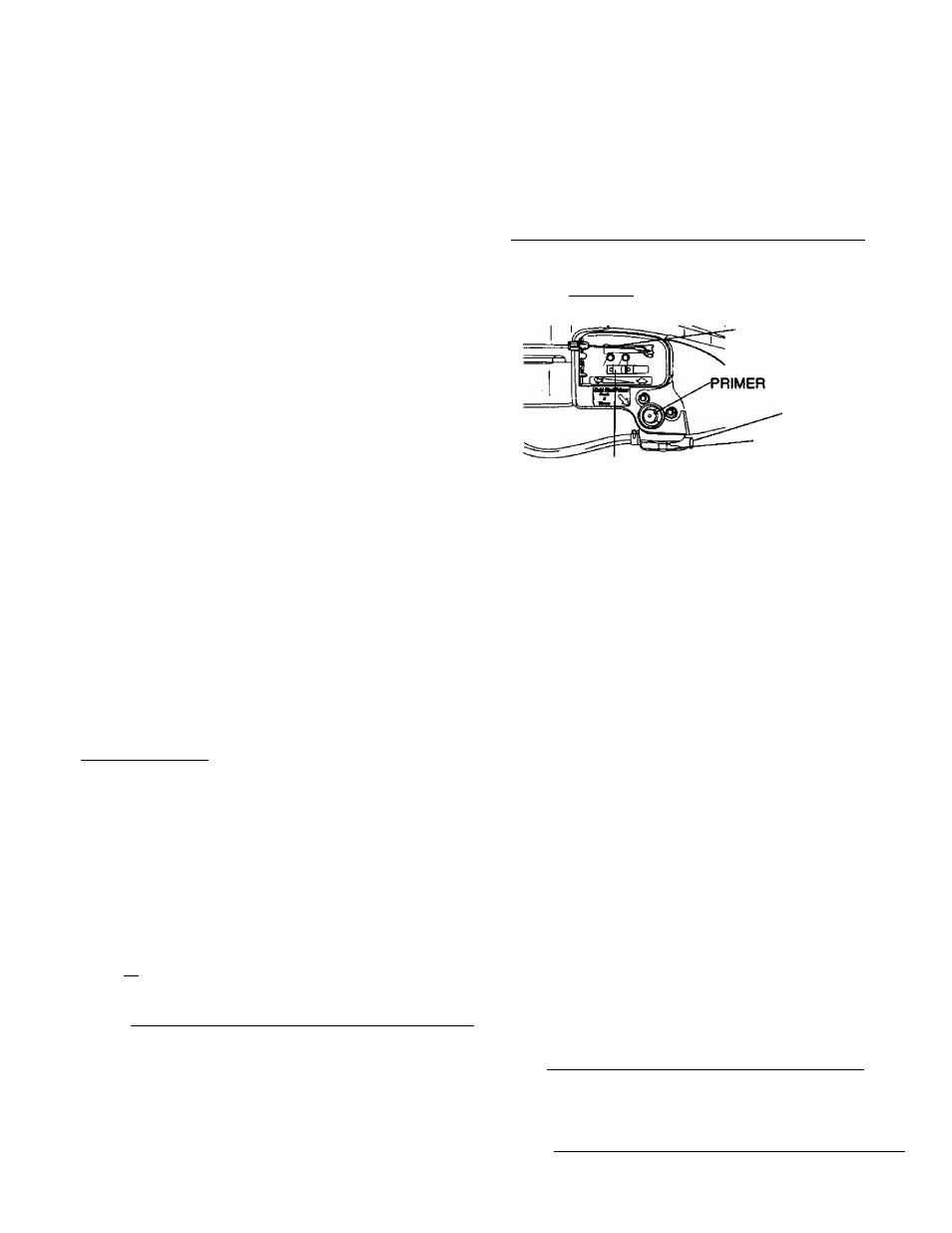

ENGINE WITH PRIMER

1) Move control lever (figure 2) to “FAST or “START (see

equipment manufacturer’s instructions).

2) The carburetor on your engine has been completely adjusted

at the factory. When starting a cold engine, push red primer

bulb firmly with your thumb 3 times, allowing primer bulb to

return completely to original position between pushes. Re

peat the above for each starter operation as necessary.

NOTE: DO NOT USE PRIMER TO RESTART A WARM

ENGINE AFTER A SHORT SHUTDOWN.

Operate mower control to release engine brake.

3)

4)

a) RECOIL STARTERS: Grasp starter handle (figure 3) and

pull rope out slowly until you feet drag. Let rope rewind

slowly. Pull rope with rapid, full arm stroke. Return rope

slowly to original position.

NOTE: If engine fails to start after three pulls, repeat steps

2-3 above.

b) ELECTRIC STARTERS: Crank engine.

NOTE:

If engine does not start after five seconds of

cranking, stop and repeat steps 2-3 above.

NOTE; If equipped with a snap-in control as shown, no

adjustment is required.

A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH

A

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES

DISENGAGED. (FOLLOW EQUIPMENT MANU

FACTURER’S INSTRUCTIONS.) THIS SHOULD PLACE

ANY SAFETY SWITCH ES IN SAFE STARTING POSITION.

STOPPING

O See mower manufacturer's instructions.

® AFTER ENGINE IS STOPPED:

B. Be sure spark plug wire is attached to spark plug (see Figure

1

).

A

A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

I__ AND ATTACH IT TO RETAINING POST (see Figure 6L

. B. NEVER STORE ENGINE WITH FUEL IN TANK IN DOORS

OR IN ENCLOSED, POORLY VENTILATED AREAS,

WHERE FUEL FUMES MAY REACH AN OPEN FLAME,

SPARK OR PILOT LIGHT AS ON A FURNACE, WATER

HEATER. CLOTHES DRYER OR OTHER GAS APPLIANCE.

Page 2

181-1183-11