Operation – Sears 390.2508 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

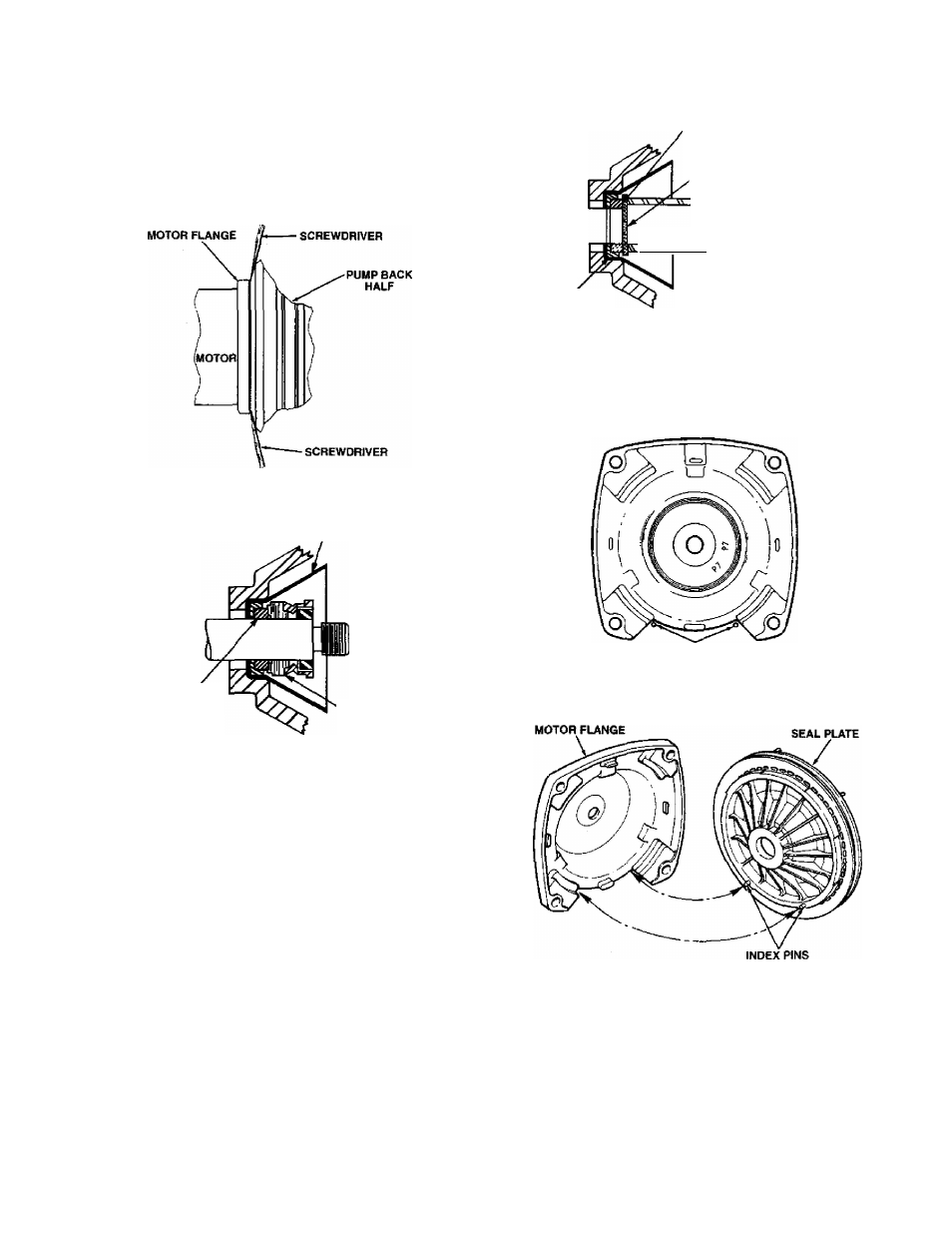

3. Remove seal plate from motor by inserting two screw

drivers between the seal plate and the motor flange. Pry

seal plate off motor flange. This will force rotating portion

of seal off shaft,

NOTE; Be sure you do not scratch shaft!

See Figtjres 7 & 8.

POLISHED SURFACE

OF FLOATING SEAL

CARDBOARD WASHER

FURNISHED WITH SEAL

vv vv y. w

3/4" PIPE

CUP SEAL

Figure 9

F. Reassemble seal plate to motor flange. BE SURE it is

right side up: index pins should be down; seal plate

is marked at top. See Figures lOA and lOB.

TOP OF MOTOfl FLANGE

Figure 7

COPPER SEAT

FLOATING

SEAT

SEAL PLATE INDEX PINS

SLIDE IN HEflE

Figure lOA

ROTATING

MEMBER

Figure 8

4. Place seal plate face down on flat surface and tap out ce

ramic seat.

NOTICE: Do not force out copper insert. If it has moved,

leakage will occur. See section on installing copper insert on

Page 9.

5- Clean seal cavity.

6. Install new seal.

A. Clean polished surface of ceramic seat with clean

cloth.

B. Wet outer edge of cup seal with petroleum jelly or de

tergent solution.

C. With finger pressure, press firmly and squarely into

cavity. Polished face of seat faces inside of pump. If

seat will not locate properly, place cardboard washer

over polished face and use piece of 3/4" standard pipe

for pressing purposes. See Figure 9.

D. Dispose of cardboard washer and clean surface of

seat.

E. Clean motor shaft.

Figure I OB

G. Apply detergent solution to inside diameter of rotat

ing seal member.

H. Slide rotating member on shaft until rubber drive ring

hits shaft shoulder.

NOTE: Be sure you do not chip or scratch seal face

on shaft shoulder or seal will leak!