Off-season storage – Sears 645B User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE:

When reassembling, make certain thi} open

ing on the back-up plate is toward the bottom of the

unit. The back-up plate may be reversed to piovide a

new cutting edge.

Allen

Screws

FIGURE 16.

Torque

Wrench

5.

Loosen the two hand knobs and cupped washers

which

secure

the

chute

deflector,

and

raise

the

chute deflector.

6

.

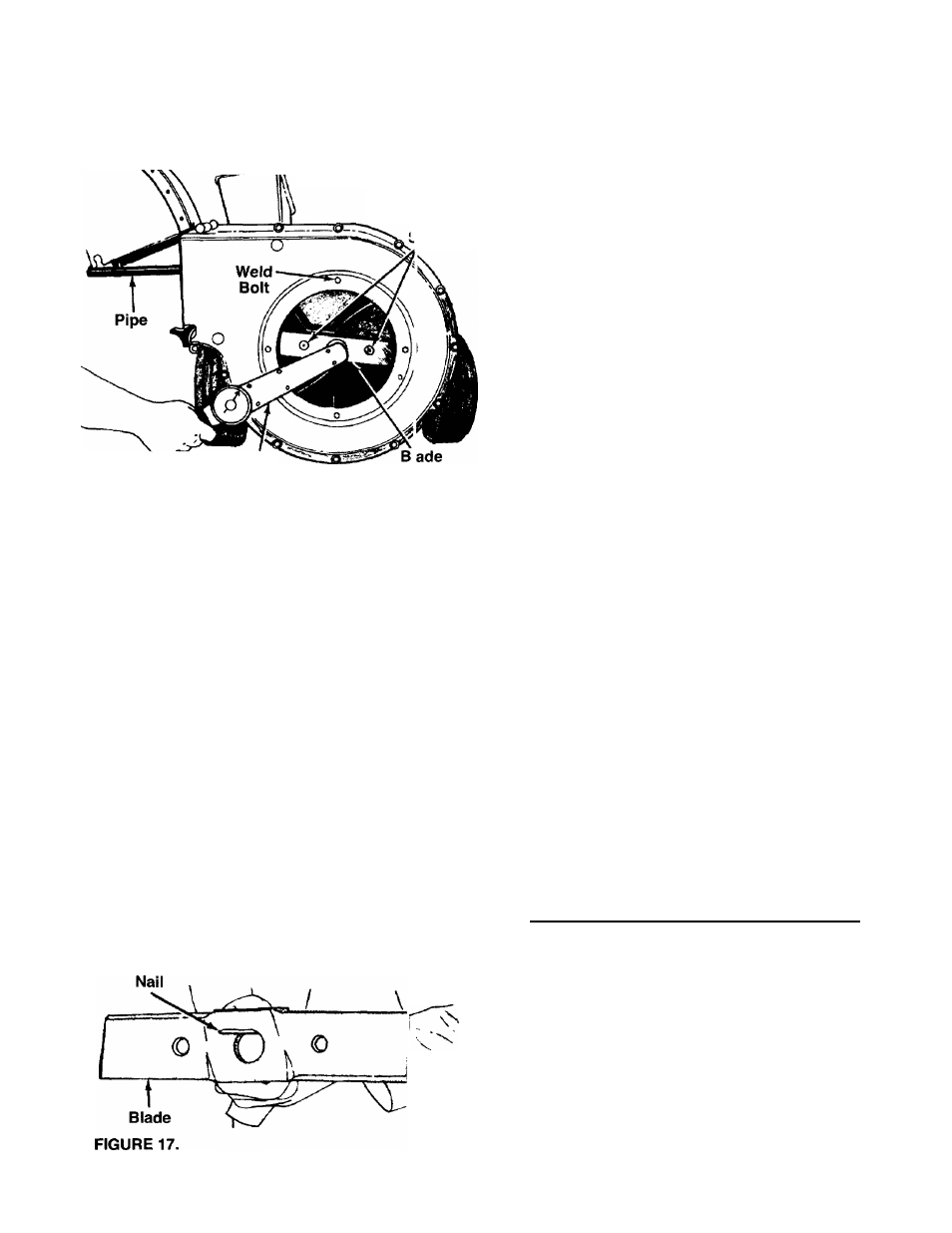

Insert a 1/2" or 3/4” diameter pipe through the flail

screen into the impellers assembly to keep it from

turning, or remove the flail screen, and insert a

piece of wood (2 x 4) into the chute openi ig.

7.

Remove

the

two

outside

screws

on

the

blade,

using a 3/16" alien wrench and a 1/2" wrench.

8

.

Remove the blade by removing the cer ter bolt,

lock washer and flat washer.

NOTE:

Use caution when removing the blade to avoid

contacting the weld bolts on the housing.

When sharpening the blade, follow the origir al angle

of grind as a guide. It is extremely important tiat each

cutting edge receives an equal amount of gr nding to

prevent

an

unbalanced

blade.

An

unbalanced

blade

will

cause

excessive

vibration

when

rotatinc

at

high

speeds and may cause damage to the unit.

The blade can be tested for balance by balancing it

on

a

round

shaft

screwdriver

or

nail.

Remo/e

metal

from the heavy side until it is balanced evenly. See

figure 17.

When

reassembling

the

blade,

tighten

to

between

550

and 650 inch pounds, or lacking torque wrench, tight

en securely.

FLAILS

The

flails,

located

inside

the

housing,

may

be

reversed when they become dull. It is suggested that

this

procedure

be

performed

by

your

nearest

authorized dealer.

CARBURETOR ADJUSTMENT

A

WARNING:

If

any

adjustments

are

made

to

the

engine

while

the

engine

is

running

(e.g.

carburetor),

keep

ciear

of

all

moving

parts.

Be

carefui

of

heated

surfaces

and

muffler.

Minor carburetor adjustment may be required to com

pensate

for

differences

in

fuel,

temperature,

altitude

or load.

NOTE: A

dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

Do

not

make

unnecessary

adjustments.

Factory

set

tings are satisfactory for most applications and condi

tions.

If

adjustment

is

needed,

refer

to

the

separate

engine manual packed with your shredder.

OFF-SEASON STORAGE

The following steps should be taken to prepare your

shredder for storage.

1. Clean and lubricate the shredder thoroughly.

2.

Refer to engine manual for correct engine storage

instructions.

3.

If

storing

in

an

unventilated

or

metal

storage

shed, coat metal parts with a light oil or silicone to

prevent rust.

4.

Store in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

10