Ignition, cooling and exhaust, Systems, B. ignition, cooling, and exhaust systems – Sears 358.356090-3.7/20" User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

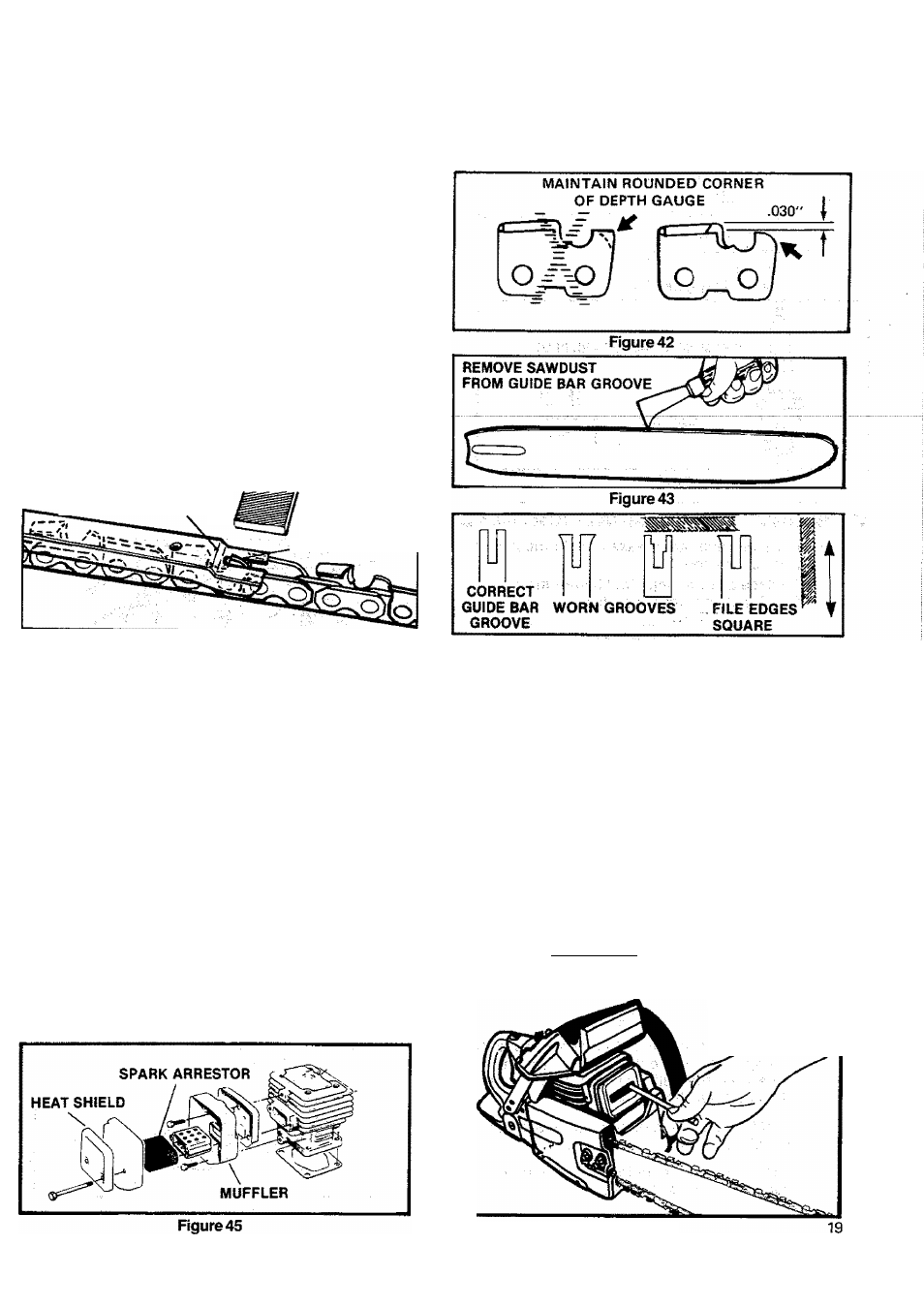

2. GUIDE BAR MAINTENANCE

• Conditions which can require guide bar

maintenance:

—saw cuts to one side

—saw has to be forced through a cut

—inadequate supply of oil to bar and

chain.

• Check the condition of the guide bar each

time the chain is sharpened.

A worn guide

bar will damage the chain and make cut

ting more difficult.

• Replace the guide bar when:

—the inside groove of the guide bar rails is

..... worn.

—the guide bar is bent or cracked.

a. Remove the guide bar to service.

b. Clean oil hoies at least once for each

five hours of operation.

.......... c:..-Remove..sawdust...from the.... guide bar

groove periodically with a putty knife or

a wire. Figure43 .

d.

e.

Remove burrs by filing the side edges

of the guide bar grooves square with a

flat file. Figure

44

,

Restore square edges to an uneven rail

top by filing with a flat file. Figure44.

JJEPTH GAUGE TOOL ^

DEPTH GAUGE

Figure 41

Figure 44

IGNITION, COOLING AND EXHAUST

• Carbon deposits will build up on exhaust

ports, spark arrestor, muffler, and spark plug

as the saw is used. All of these parts should

be cleaned at the same time to prevent

engine damage, overheating, loss of power,

and hard starting. >

• Clean parts:

—as required

—at least once for each 25-30 hours of op

eration

1. COOLING AND EXHAUST SYSTEM

• Carbon build-up on the cooling and ex

haust system can cause the engine to

loose power in a cut.

• Keep the spark arrestor clean at all times.

• Replace the spark arrestor when breaks in

the screen are found.

SYSTEMS

and

items required:

—wire brush

^ ^ ^ ^ ^ ^ ^ ^ ^

—3/8” wrench

—hardwood stick

a. Disconnect the spark plug.

Remove the rnuffler, baffles,

screen. Figure 45.

Pull the starter rope until the piston

moves far enough to close the exhaust

ports. V

Scrape the carbon deposits from the

exhaust ports and surrounding exhaust

chamber using a hardwood stick.

Figure 46.

b.

d.

¡CAUTION:] Do not use a metallic scrap-

SCRAPE CARBON

DEPOSITS FROM

EXHAUST PORTS

Figure 46