A warning, Temperature rise adjustment, Care and maintenance – Carrier 58SSB User Manual

Page 6: A caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING

SPEED

TRIM POT

TO BLOWER'

A WARNING

To avoid possibility of electrical shock, be sure to

disconnect electrical power before removing access

panels.

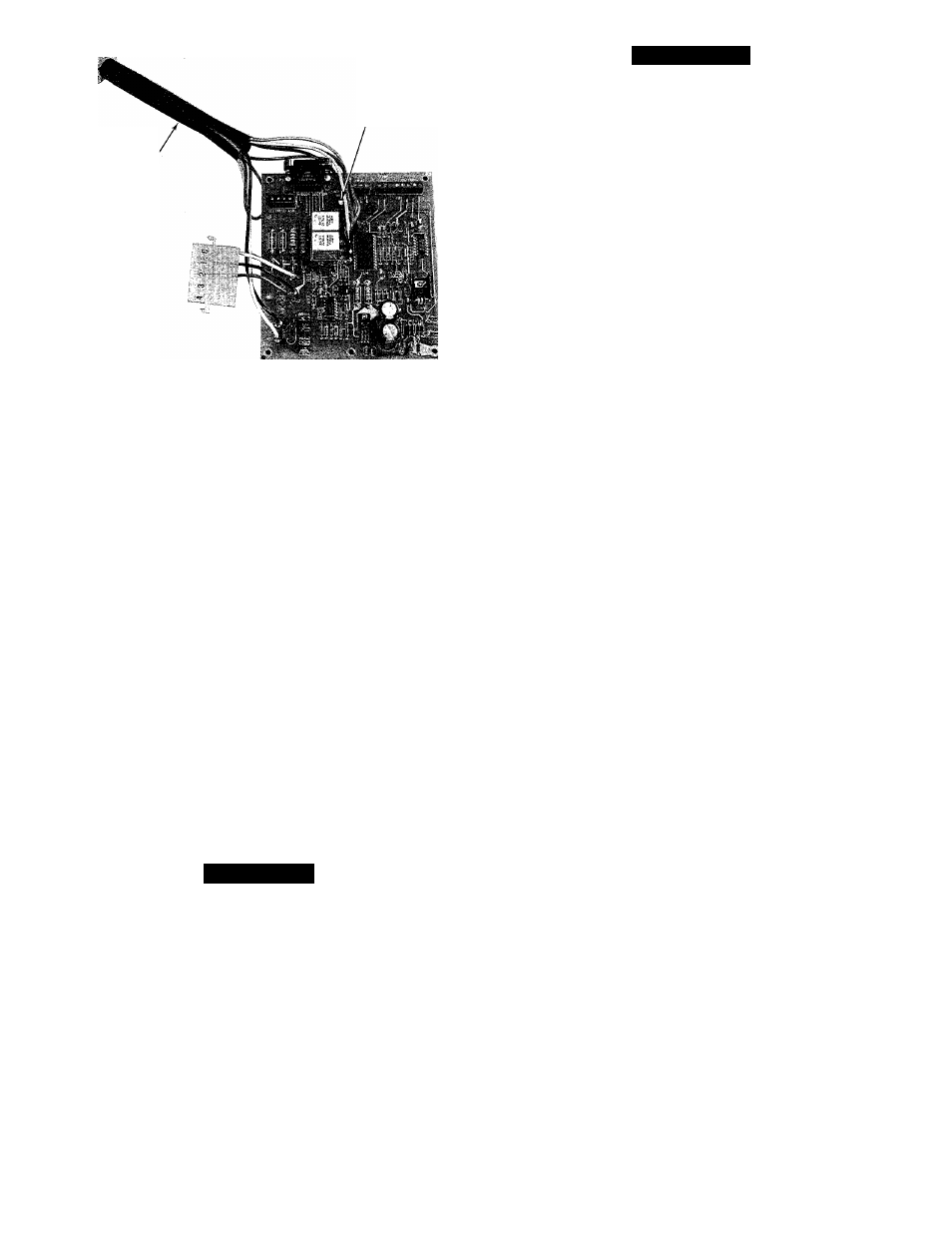

Fig. 8 — Variable Speed Blower Interface Board

TEMPERATURE RISE ADJUSTMENT

Furnace must not be operated outside range of tem

perature rise specified on unit rating plate. Determine

air temperature rise as follows;

1. Place thermometers in return and supply ducts as

near furnace as possible. Be sure thermometers do not

see heating element so that radiant heat does not

affect readings. This practice is particularly important

with straight run ducts.

2. When thermometer readings stabilize, subtract return-

air temperature from supply-air temperature to deter

mine air temperature rise.

NOTE: If outdoor section and system thermostat are

not installed, temperature rise can be determined by

jumpering R and W circuits on furnace control board.

3. Adjust temperature rise to midpoint of temperature

rise range specified on unit rating plate by adjusting

blower speed. To adjust blower speed locate heating

speed trimpot in interface circuit board (see Fig. 8).

Increase blower speed clockwise to reduce tempera

ture rise. Decrease blower speed counterclockwise to

increase temperature rise.

CARE AND MAINTENANCE

A CAUTION

Because of possible damage to the equipment or

personal injury, maintenance should be performed

by qualified persons only.

For long life, economy and high efficiency, clean

accumulated dirt and grease from blower wheel and

motor annually.

The following steps should be performed by a qualified

service person:

Some motors have prelubricated sealed bearings and

require no lubrication. These motors can be identified

by the lack of oil ports on each end of the motor. For

those motors with oil ports:

Lubricate motor every 5 years if motor is used on inter

mittent operation (thermostat FAN switch in AUTO,

position), or every 2 years if motor is in continuous

operation (thermostat FAN switch in ON position).

Clean and lubricate as follows:

1. Remove access panels.

2. Disconnect R, W, and C thermostat leads on furnace

control board.

3. Remove control box from bottom side of blower

shelf and position out of way.

4. Note location of wires for reassembly. Remove elec

trical leads from numbered panel mount connector

located on left side of interface box.

5. Disconnect 15-conductor cable on interface circuit

board.

6. Note location of thermostat wires for reassembly.

Remove electrical leads from terminal block,TB4 on

interface circuit board.

7. Remove cover of auxiliary junction box. Disconnect

power leads going to interface circuit board.

8. Remove screws securing blower assembly to blower

shelf and slide blower assembly out of furnace.

9. Squeeze release tabs on connector PL2 and pull from

ECM blower controller.

10. Mark blower wheel location on shaft and motor

support location on motor before disassembly to

ensure proper reassembly.

11. Loosen setscrew holding blower wheel on motor

shaft.

12. Remove bolts holding motor mount to blower hous

ing. Slide motor and mount out of housing.

13. Lubricate motor.

a. Remove dust caps or plugs from oil ports located

at each end of motor. If motor does not have these

caps or plugs, bearings are sealed and need no

further lubrication.

b. Use a good grade of SAE 20 nondetergent motor

oil. Put one teaspoon (5 cc, 3/16 oz or 16 to 25

drops) in each oil port. Use of other types or

grades of oil will damage motor. Excessive oiling

can cause premature bearing failures.

c. Allow time for total quantity of oil to be absorbed

by each bearing.

d. After oiling motor, wipe excess oil from motor

housing.

e. Replace dust caps or plugs on oil ports.

14. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff plate

location to ensure proper reassembly.

b. Remove screws securing cutoff plate and remove

cutoff plate from housing.

c. Remove blower wheel from housing.

15. Clean blower wheel and motor by using a vacuum

with soft brush attachment. Be careful not to disturb

balance weights (clips) on blower wheel vanes. Do

not drop or bend wheel because balance will be

affected.

16. Reassemble blower by reversing steps 14a through c.

Be sure wheel is positioned for proper rotation and

motor oiling plugs are pointed up when motor is

installed.