Maintenance – Homelite 8H.P User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Figure 10

CLUTCH

DEPTH BAR

See Figure 6. The depth bar setting determines the depth

of tilling. To till 4 to 6 inches deep, install the bar mount

ing pind'n the second or third hole from the TOP. Pull out

the hairpin clip to change pin location. Be sure to install

the bar with the digging tip as shown. THE DEEPER THE

DEPTH BAR IS SET INTO THE SOIL, THE DEEPER

THE TINES WILL DIG.

CARBURETOR

Minor carburetor adjustments may be required to com

pensate for differences in fuel, temperature, altitude and

load. See your engine owner's manual for adjustment pro

cedures.

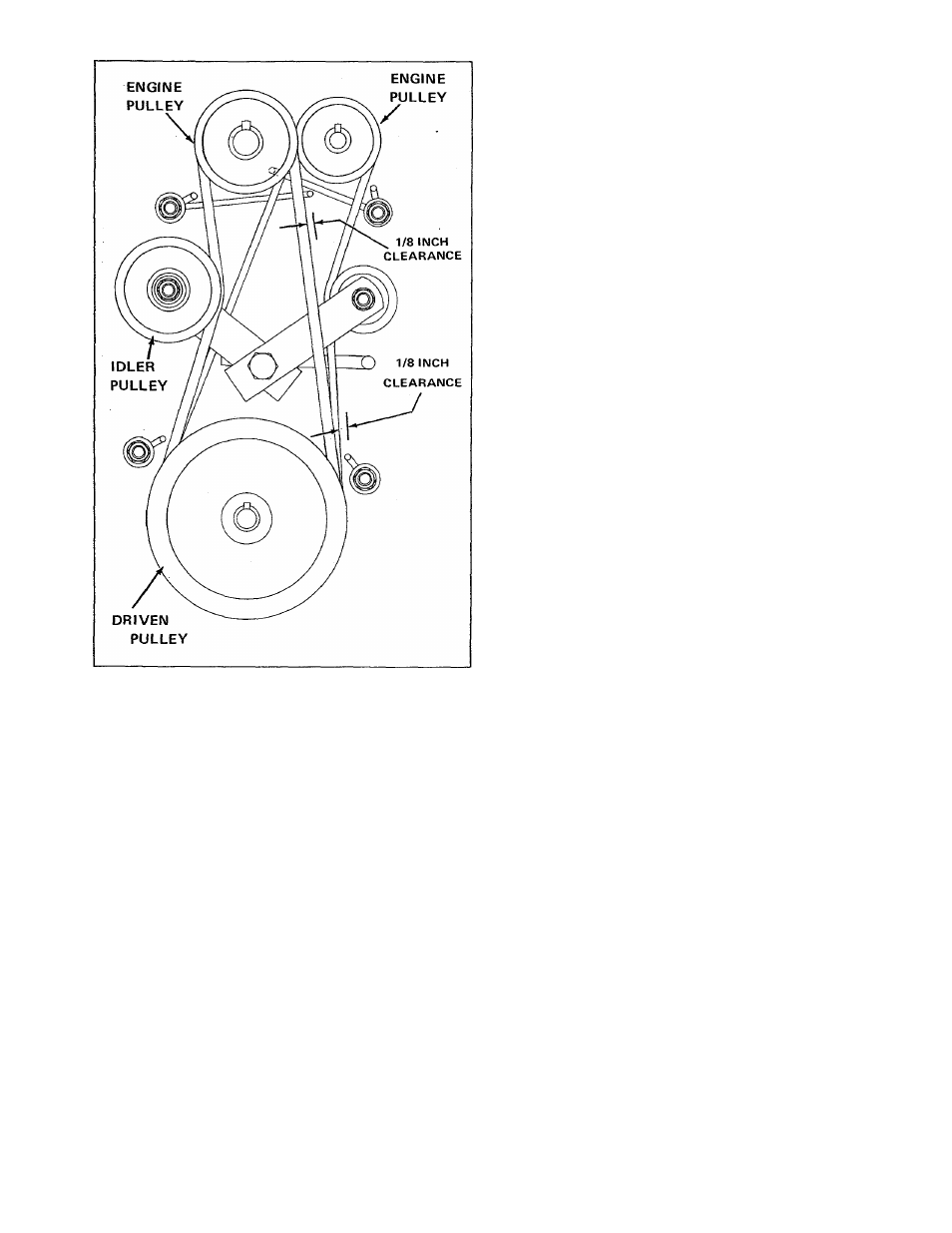

PULLEY ALIGNMENT

See Figure 10. Visually check alignment of engine, idler,

and driven pulleys. Pulleys must be aligned as closely as

possible or belts will be stretched and worn excessively.

Loosen engine and/or driven pulley setscrews and align

pulleys. Tighten setscrews securely.

MAINTENANCE

Read the engine owner's manual thoroughly.

AFTER EACH USE

Grass, dirt, or chaff may clog engine cylinder head fins and

blower housing. Check for clogged condition and if nec

essary remove blower housing and clean.

1. When clutch disengaged (handle released), idler pulleys

should be no closer than 1/4-inch from frame and all belt

stops must be firmly gripping the drive belts.

2. When clutch engaged (handle compressed), idler pulley

must press in on belt enough to remove belt from contact

with belt stops. Approximately 1/8-inch clearance between

belt stop and belt should be maintained. See Beit Stop

Adjustment.

3. See Figure 5. If clutch does not operate as described

above in steps 1 and 2, loosen wire clamp setscrew and ad

just wire clamp on forward or reverse control rod to obtain

required spring tension.

SCRAPERS

Loosen scraper mounting nut and adjust scraper in its slot

to 1/8-inch clearance above wheels. Tighten nut when

adjustment completed.

CAUTION

Continued operation with a clogged cooling system

causes severe overheating and possible engine damage.

FIRST 5 HOURS OF OPERATION

See Figure 9. Change engine oil as follows:

a. Run engine for a few minutes to warm engine oil.

b. Remove oil drain plug and allow oil to completely

drain from engine.

c. Replace oil drain plug securely.

d. Remove dirt around engine oil filler plug.

e. Remove engine oil filler plug by turning counter

clockwise.

f. Fill with SAE 30 grade MS oil until level with top of

neck. Crankcase capacity is 2-3/4 pints.

g. Reinstall engine oil filler plug securely.