Homelite 8H.P User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

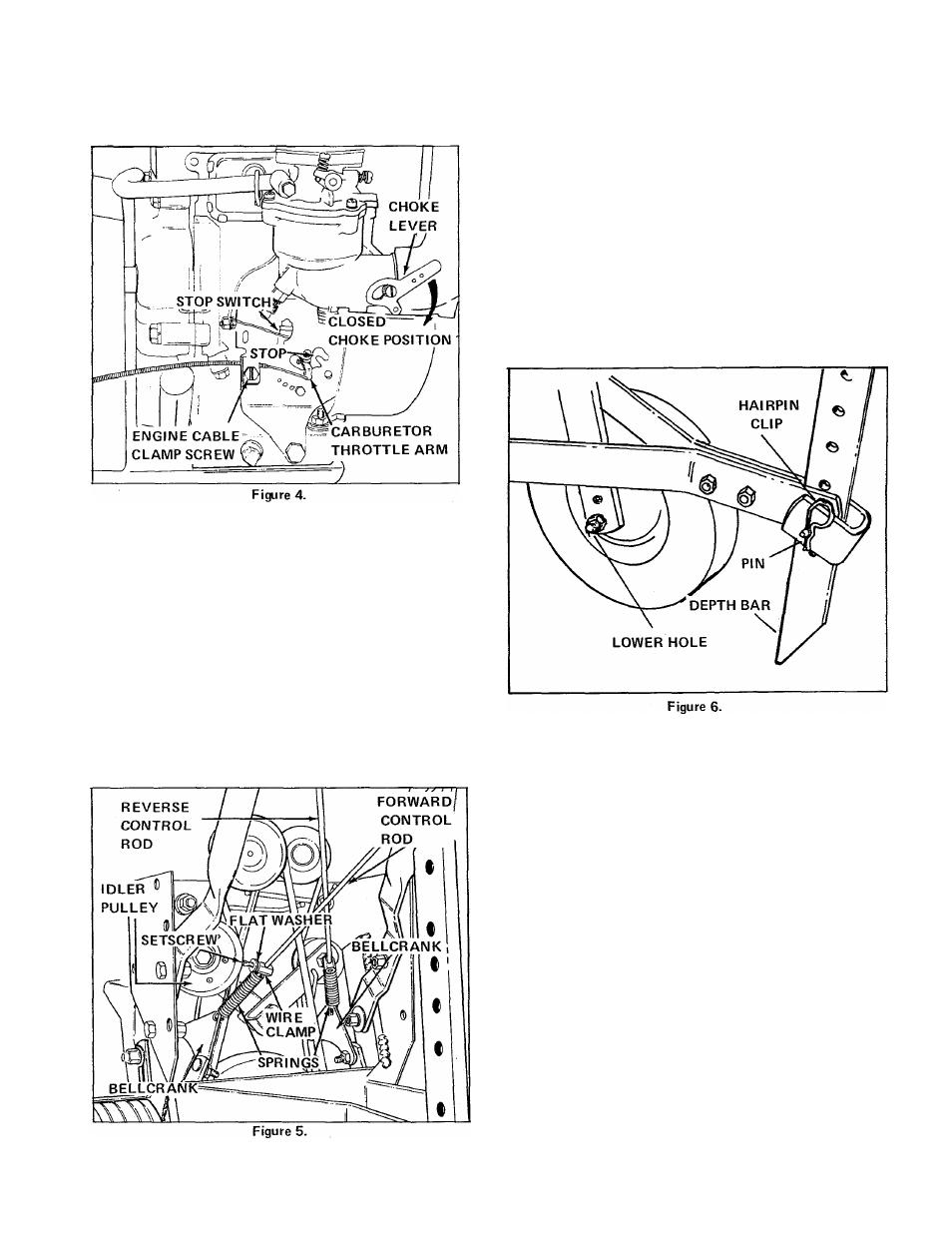

arm, the throttle cable must be secured to the right

handle with a clip. The cable must then pass outside the

right side of the cover and through a engine cable clamp.

Loosen engine cable clamp screw as required. See Figure

4.

b. See Figure 4. Insert loose wire end of throttle cable

in carburetor throttle arm. Lever should be in forward

position against stop in slot. Tighten engine cable clamp

screw.

c. See Figure 8. Move throttle control handle to STOP

position. Be sure stop switch opens. See Figure 4.

5. Install forward and reverse control rods as follows:

a. See Figure 5. Attach reverse and forward control rod

springs to bellcranks.

b. See Figure 5. Slide reverse and forward control rods

through wire clamps inside springs. Loosely secure rods

in clamps with setscrews and flat washers. Hook loose

end of springs on setscrews between flat washers and

clamos.

c. See Figure 5. Adjust spring tension by loosening clamp

setscrews and moving clamps on control rods. Idler

pulleys should be 1/4-inch from frame when clutch dis

engaged (handle released). Belt stops should be 1/8-inch

from belts when clutch engaged (handle compressed. See

Adjustments section of this manual for clutch adjustment

procedure.

d. Secure cover to frame with six self-tapping screws.

6. Install wheel assemblies as follows:

a. Tilt unit forward on engine.

b. See Figure 6. Secure each wheel assembly (bushing

inward) to frame through lower holes in frame support

with a 3-1/2-inch long shoulder bolt, lockwasher, and

hex nut. Tighten hex nut.

7. See Figure 6. Secure depth bar and clamp to rear of

frame with pin and hairpin clip. Digging tip of bar should

be installed as shown.

NOTE:

The depth bar setting determines the depth of

tilling. To till 4 to 6 inches deep, install bar mounting pin

in second or third hole from the top. The deeper depth bar

is set into soil, the deeper tines will dig.

8. Loosen each wheel scraper nut and adjust scraper to

clear wheel by 1/8-inch. Tighten scraper nut.

9. Depending upon what tilling width desired, install right

and left tine blade assemblies as follows. Use a pin and

hairpin clip for installation. See Figure 7 for right inner,

outer and extension tine installation.