Burners, Gas input, Table 2 — gas rate (cubic feet per hour) – Carrier 58 Series User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

nace. However, when lighting the pilot for the first

time, perform the following additional steps;

■ 1. If supply line was not purged before connecting

furnace, it will be full of air. It is recommended

that the ground joint union be cracked, and sup

ply line be allowed to purge until odor of gas is

detected. Never purge gas lines into combustion

chamber. Immediately upon detection of gas

odor, retighten the union. Allow 5 minutes to

elapse, then light pilot in accordance with in

structions on furnace.

2. Pilot flame should be soft blue in color.

a. For natural gas controls, flame should be long

enough to provide good impingement on ele

ment of pilot. Flame should extend above the

carryover ports of the burner.

b. For complete shutoff gas controls, flame

should surround tip of thermocouple element

of pilot and extend downward to include 3/8

to 1 / 2-in. of thermocouple. Flame must never

come in contact with any other part of ther

mocouple or its lead wire. Flame lies under

carryover port of burner and merges with

carryover flame.

3. Pilot adjusting screw is located on main gas valve

or pilot shutoff valve.

a. Remove capscrew; turn pilot gas full on and

turn adjusting screw until desired appearance

is obtained.

b. Replace capscrew.

4. For natural gas controls, check the pilot oper

ation as follows: Attach a low-voltage test light

to electrical leads of gas valve. With thermostat

set above room temperature, shut off gas supply

to burners and pilot with main manual shutoff

valve. If test light goes out within 45 seconds,

pilot is functioning properly. If light does not go

out within 60 seconds, replace pilot.

5. The 100% safety control can be easily checked

by unscrewing pilot thermocouple lead from gas

valve. Pilot and main burner gas should shut off

— no gas should flow thru valve. After valve is

checked and found to operate satisfactorily,

reconnect thermocouple to gas valve to finger-

tight position. Then tighten 1/4 turn with a

wrench. Relight pilot, following lighting instruc

tions on furnace.

Burners

— Light main burners using procedure

contained on Lighting Instruction Plate attached to

furnace.

Gas Input

— Determine the gas input as follows:

NATURAL GAS

1. Turn off all other gas appliances and pilots.

2. Measure time (in seconds) for gas meter test dial

to complete one revolution.

3. Refer to Table 2 for cu ft of gas per hour.

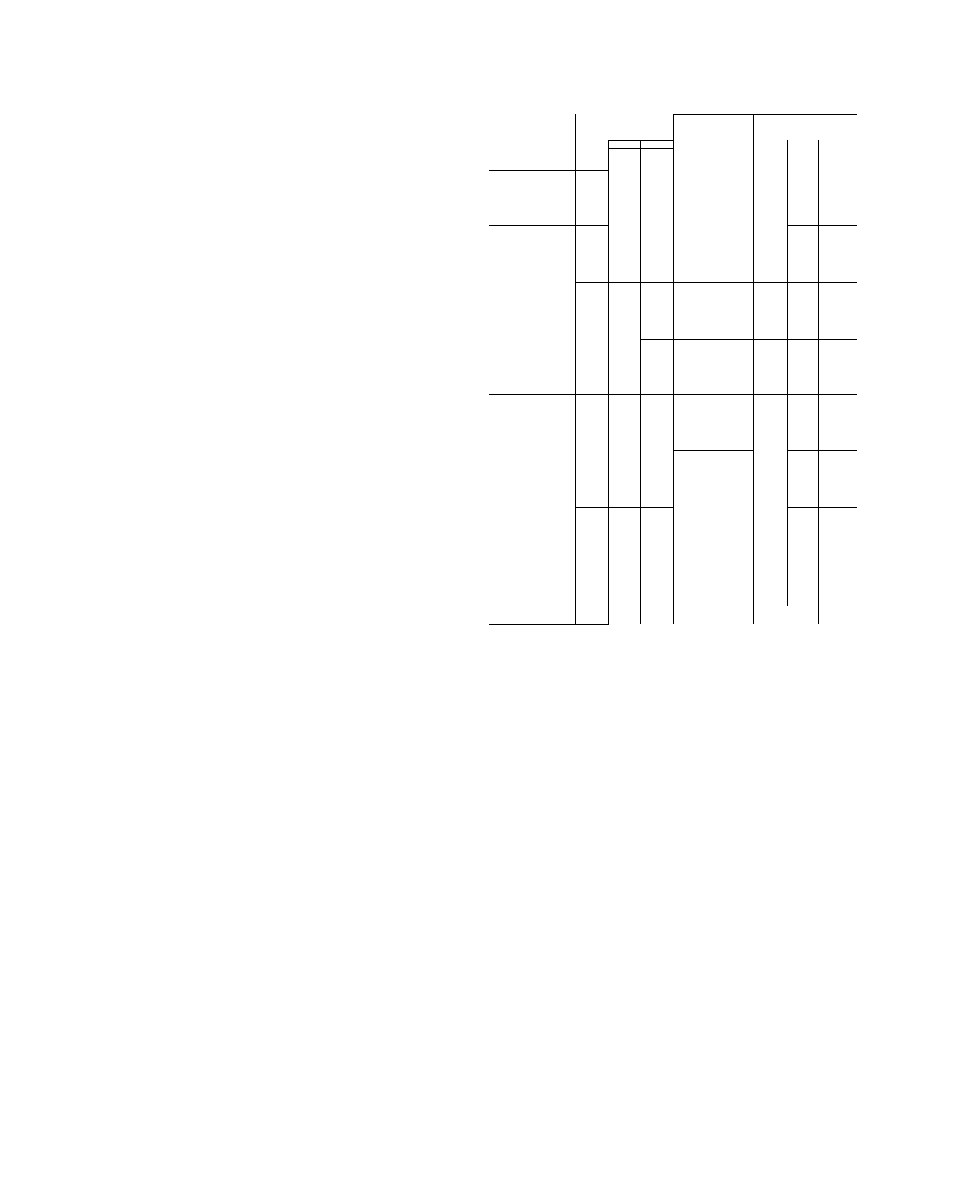

Table 2 — Gas Rate (Cubic Feet Per Hour)

SIZE OF

SIZE OF

SECONDS

TEST DIAL

SECONDS

TEST DIAL

FOR ONE

FOR ONE

»»"— --- ---- ,

REVOLUTION

1

2

5

REVOLUTION

1

2

5

cu ft

cu ft

cu ft

CU ft

cu ft

cu ft

10

360

720

1800

50

72

144

360

11

327

655

1636

51

71

141

355

12

300

600

1500

52

69

138

346

13

277

555

1385

53

68

136

340

14

257

514

1286

54

67

133

333

15

240

480

1200

55

65

131

327

16

225

450

1125

56

64

129

321

17

212

424

1059

57

63

126

316

18

200

400

1000

58

62

124

310

19

189

379

947

59

61

122

305

20

180

360

900

60

60"^ 120

300

21

171

343

857

62

58

116

290

22

164

327

818

64

56

112

281

23

157

313

783

66

54

109

273

24

150

300

750

68

53

106

265

25

144

288

720

70

51

103

257

26

138

277

692

72

50

100

250

27

133

267

667

74

48

97

243

28

129

257

643

76

47

95

237

29

124

248

621

78

46

92

231

30

120

240

600

80

45

90

225

31

116

232

581

82

44

88

220

32

113

225

563

84

43

86

214

33

109

218

545

86

42

84

209

34

106

212

529

88

41

82

205

35

103

206

514

90

40

80

200

36

100

200

500

92

39

78

196

37

97

195

486

94

38

76

192

38

95

189

474

96

38

75

188

39

92

185

462

98

37

74

184

40

90

180

450

100

36

72

180

41

88

176

439

102

35

71

178

42

86

172

429

104

35

69

173

43

84

167

419

106

34

68

170

44

82

164

409

108

33

67

167

45

80

160

400

110

33

65

164

46

78

157

391

112

32

64

161

47

76

153

383

116

31

62

155

48

75

150

375

120

30

60

150

49

73

147

367

J

4.

^ 5.

Multiply cu ft per hour times heating value of

gas (Btu/ cu ft). Obtain heating value of gas from

local gas utility.

Example:

Btu/cu ft

X

cu ft = Btuh heating input

Time for one revolution of 2 cu ft dial

= 72 seconds

Heat value of gas = 1070 Btuh/cu ft

100

X

1070 = 107,000 Btuh input

Measured gas input should not exceed gas

input shown on unit rating plate.

6. To adjust input rate, remove cap that conceals

regulator adjustment. Turn adjusting screw

counterclockwise (out) to decrease input. When

adjusting, DO NOT change manifold pressure

more than 0.3 in. wg. Any major adjustment

should be made by changing main burner

orifices.

LP (PROPANE) GAS — These units are equipped

with pressure regulators. Burner orifices are sized to