A warning – Carrier 48NLT User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

to terminals Y and G. These completed circuits through the

thermostat connect contactor coil C (through unit wire Y)

and relay coil IFRl (through unit wire G) across the 24-v

secondary of transformer TRAN.

The normally open contacts of energized contactor C close

and complete the circuit through compressor motor COMP

and condenser fan motor OFM. Both motors start instantly.

The set of normally open contacts of energized relay IFRl

close and complete the circuit through evaporator blower

motor IFM. The blower motor starts instantly.

NOTE: The cooling cycle remains “on” until the room tem

perature drops to point that is slightly below the cooling

control setting of the room thermostat. At this point, the

thermostat “breaks” the circuit between thermostat termi

nal R to terminals Y and G. These open circuits de

energize contactor coil C and relay coil IFRl. The condenser

and compressor motors stop. After a 45-second delay, the

blower motor stops. The unit is in a “standby” condition,

waiting for the next “call for cooling” from the room

thermostat.

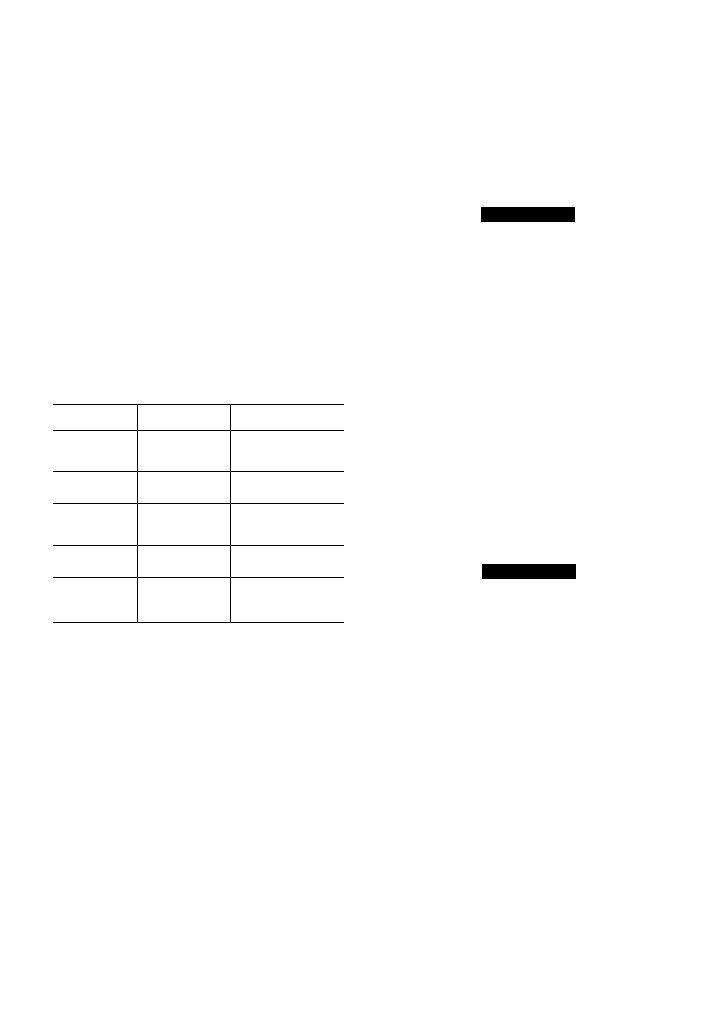

Table 10 - Wet Coil Pressure Drop

MODEL

AIRFLOW

(cfm)

WET COIL PD

(In. wg)

600

038

018,024

700

800

.044

.052

900

062

900

.042

030

1000

.050

1200

.064

1000

.038

036,042

1200

1400

.050

.064

1600

.080

1400

050

048

1600

.060

1800

.072

1700

.100

060

1900

.120

2100

.140

2300

.160

MAINTENANCE

To ensure continuing high performance, and to minimize

the possibility of premature equipment failure, periodic main

tenance must be performed on this equipment. This com

bination heating/cooling unit should be inspected at least

once each year by a qualified service person. To trouble

shoot heating or cooling of units, refer to Tables 11 and 12.

NOTE TO EQWPMENT OWNER: Consult your local Dealer

about the availability of a maintenance contract.

A WARNING

The ability to properly perform maintenance on this equip

ment requires certain expertise, mechanical skills, tools

and equipment. If you do not possess these, do not at

tempt to perform any maintenance on this equipment,

other than those procedures recommended in the Us

er’s Manual. FAILURE TO HEED THIS WARNING

COULD

RESULT

IN

SERIOUS

PERSONAL

INJURY AND POSSIBLE DAMAGE TO THIS

EQUIPMENT.

The minimum maintenance requirements for this equip

ment are as follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect cooling coil, drain pan and condensate drain each

cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel for cleanliness and check

lubrication each heating and cooling season. Clean and

lubricate (if required) when necessary.

4. Check electrical connections for tightness and controls

for proper operation each heating and cooling season.

Service when necessary.

5. Check and inspect heating section before each heating

season. Clean and adjust when necessary.

6. Check and clean vent screen if needed.

A

warning

Failure to follow these warnings could result in serious

personal injury:

1. Turn off gas supply,

then

turn off electrical power

to the unit before performing any maintenance or

service on the unit.

2. Use extreme caution when removing panels and parts.

As with any mechanical equipment, personal injury

can result from sharp edges, etc.

3. Never place anything combustible either on, or in

contact with, the unit.

4. Should overheating occur, or the gas supply fail to

shut off, shut off the external main manual gas valve

to the unit,

then

shut off the electrical supply.

I

I

20