Winco ULPSS20B4W/A User Manual

Page 7

7

20-00

60706-228

FEET

SIZE OF PIPE

up to 25 FT*

3/4 “ Pipe

25 - 100 FT*

1” Pipe

over 100 FT*

Use a two regulator

system.

* Allow an additional 3 feet for each standard

elbow. Do not use ‘street ells’ (restrictive).

NATURAL GAS (NG)

The primary regulator (fuel meter) on the building

should deliver the correct volume and pressure to

the generator set. This regulator must be sized to

deliver the required BTU’s to the generator set and

all other appliances in the building.

If the primary

regulator (fuel meter) is a high pressure regu-

lator, then a low pressure regulator must be

installed to bring the pressure down to 4-6 oz.

(7-11 inches water column) of pressure. This low

pressure regulator must be at least 10 feet from

the engine generator set; any closer installation

will require a larger line be installed to provide a

fuel reservoir. If this is not done, the demand regu-

lator on the unit and the pressure regulator in the

fuel line will interfere with each other. This regulator

must be sized to accommodate the demand of the

generator set and any other appliance connected to

it. See table below for the correct size of pipe to be

installed.

FEET

SIZE OF PIPE

up to 25 FT*

3/4 “ Pipe

25 - 100 FT*

1” Pipe

over 100 FT*

Consult Factory

* Allow an additional 3 feet for each standard

elbow. Do not use ‘street ells’ (restrictive).

******************

***** WARNING *****

******************

PERSONAL DANGER - Do not use galvanized pipe

in fuel line runs. The galvanized coating can be-

come eroded and flake off, causing possible obstruc-

tions in the regulator or fuel valve. The results could

range from inoperative engine to hazardous fuel

leaks.

**** CAUTION ****

Be careful when sealing gas joints. Excessive seal-

ing compound can be drawn into the solenoid, regu-

lator or carburetor causing an engine malfunction.

FUEL PRESSURE

LP & NG VAPOR FUEL Correct fuel pressure can-

not be stressed enough. The most common cause

for inoperative systems is an inadequate or incor-

rect fuel pressure. Performance of the engine is in

direct relation to the correctness of the fuel system.

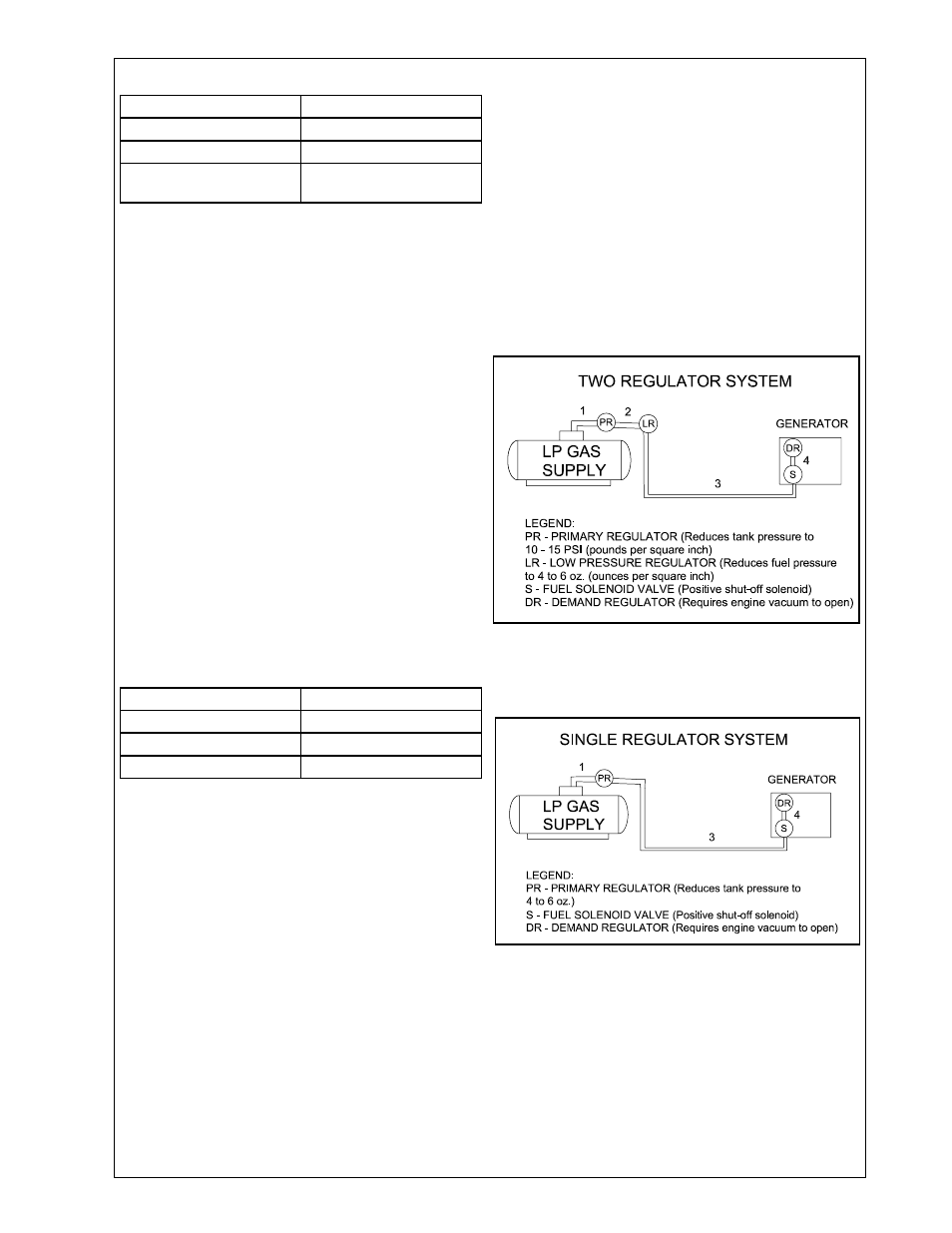

Shown below is a diagram of a typical LP vapor fuel

installation. Notice the following tables give two

(2) different units of measuring fuel pressure. The

first and most accurate is the use of a simple water

manometer. A manometer is calibrated in inches of

water column. The second is with a pressure gauge

calibrated in ounces per square inch.

Reference numbers through 3 in the diagrams

above are system parts supplied by the customer.

Reference number 4 is on the generator.