Optional fuel solenoid installation instructions – Winco HPS9000E User Manual

Page 11

Page 9

60707-112

HPS 12/97

OPTIONAL FUEL SOLENOID

INSTALLATION INSTRUCTIONS

(see page 4 Installing the Fuel Line)

PARTS REQUIRED

1. ¾” 12 volt DC vapor fuel solenoid, WINCO part number

42942-000

2. 120 volt AC single pole relay (SPDT), WINCO part

number 59944-001.

3. Single pole push button switch, normal open with

momentary contacts. Purchase locally.

4. Electrical box and cover, 4” X 4”. Purchase locally

ASSEMBLY INSTRUCTIONS

a. Mount the relay inside the electrical box and the push

button switch in the cover of the box. Mount the box in a

convenient location on the unit

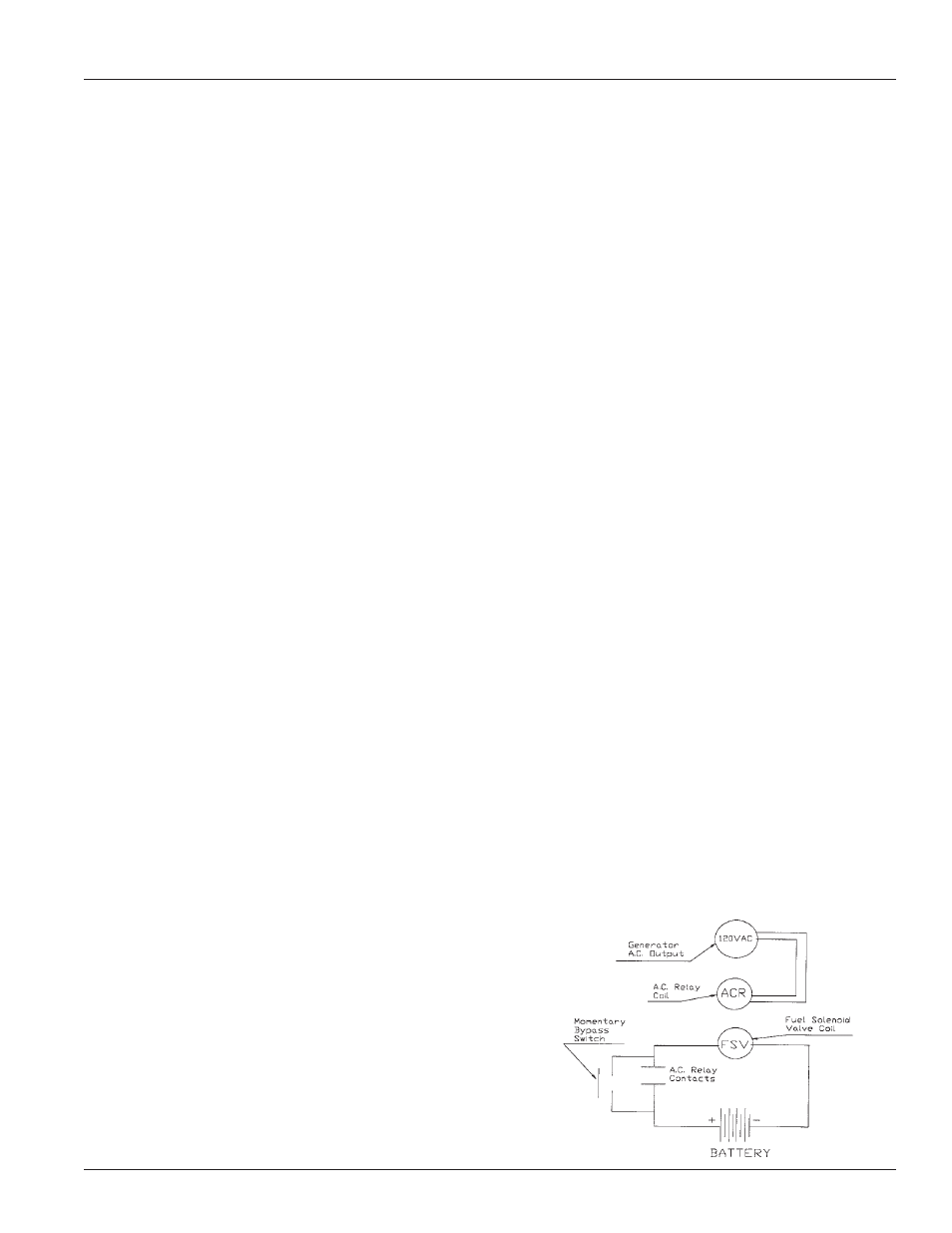

b. Connect the coil leads of the 120 volt AC relay to the

generator output. This may be done either by installing a

power cord and plugging it into one of the 120 volt outlets,

or by hard wiring it to the generator output leads in the end

cover of the generator.

c. Connect one of the leads on the fuel solenoid to the

negative side of the battery.

d. Connect the positive side of the battery to one of the

normally open contacts on the 120 volt AC relay. Also

connect one side of the momentary push button switch to

the same contact on the 120 volt AC relay.

e. Connect the second lead from the fuel solenoid to the

other side of the normally open contacts on the 120 volt AC

relay. Also connect the other side of the push button switch

to the same contact on the 120 volt AC relay.

f.

To start the unit the push button switch must be

depressed and held until the unit starts up and the

generator has time to build output, about one to two

seconds after the engine reaches operating speed.

g. At that time the 120 volt AC relay will close and the fuel

solenoid will remain powered through the relay. If the

generator or engine should fail, the AC output from the

generator will disappear. The relay will open from the loss

of power, closing the fuel solenoid, shutting off the fuel flow.

b. Receptacles - Quality receptacles have been utilized.

If a receptacle should become cracked or otherwise

damaged, replace it. Using damaged or cracked

receptacles can be both dangerous to the operator

and destructive to the equipment.

CLEANING

Remove dirt and debris with a cloth or brush. DO NOT use

high pressure spray to clean either the engine or the

generator. This high pressure spray could contaminate the

fuel system and the generator components.

1. Keep the air inlet screen on both the engine and

generator free of any dirt or debris to insure proper

cooling. At least yearly remove the blower housing on

the engine and clean the chaff and dirt out of the engine

cooling fins and flywheel. Clean more often if

necessary. Failure to keep these areas clean may

cause overheating and permanent damage to the unit.

2. Periodically clean muffler area to remove all grass, dirt

and combustible debris to prevent a fire.

3. On engine mufflers equipped with spark arresters, the

spark arrester must be removed every 50 hours for

cleaning and inspection. Replace if damaged.

TROUBLESHOOTING HINTS

PROBLEM (SYMPTOMS) POSSIBLE CAUSES

——————————————————————————

Won’t Start

*Low Oil Level.

*Fouled spark plug.

*Out of fuel.

*Stop switch in stop position.

——————————————————————————

Voltage too low

*Engine speed is too low.

*Generator overloaded.

*Defective rectifier.

*Defective stator.

*Defective rotor (field).

——————————————————————————

Circuit Breaker

*Defective load.

Trips

*Defective receptacle.

——————————————————————————

Voltage too high

*Engine speed is too high.

——————————————————————————

Generator

*Overloaded.

overheating

*Insufficient ventilation.

——————————————————————————

No output voltage

*Short in load (disconnect).

*Broken or loose wire.

*Defective receptacle.

*No residual magnetism

(in generator).

*Defective stator.

*Defective rotor (field).

*Shorted capacitor.

*Defective rectifier.

——————————————————————————