Specifications, Appendix b – Conair GB/ WSB User Manual

Page 108

One Conair Drive

●

Pittsburgh, PA 15202

●

412-312-6000

●

FAX 412-312-6227

●

www.conairnet.com

MODELS

WSB240

WSB241

WSB242

WSB440

WSB441

WSB442

Performance characteristics

Batch size lbs {g}

4.4 {2000}

4.4 {2000}

4.4 {2000}

8.8 {4000}

8.8 {4000}

8.8 {4000}

Maximum throughput

lbs/hr {kg/hr}

*

993 {451}

678 {308}

518 {235}

1645 {748}

983{446}

704 {319}

Bin capacity - main ingredient

ft

3

{liter}

3.5 {99.12}

3.5 {99.12}

3.5 {99.12}

3.5 {99.12}

3.5 {99.12}

3.5 {99.12}

Bin capacity - minor ingredient

ft

3

{liter}

NA

0.5 {14.16}

0.5 {14.16}

NA

0.5 {14.16}

0.5 {14.16}

Maximum number of materials

4

5

6

4

5

6

Number of discharge valves

4

4

4

4

4

4

Number of additive feeders

0

1

2

0

1

2

Control software (# of components)

4 or 12

12

12

4 or 12

12

12

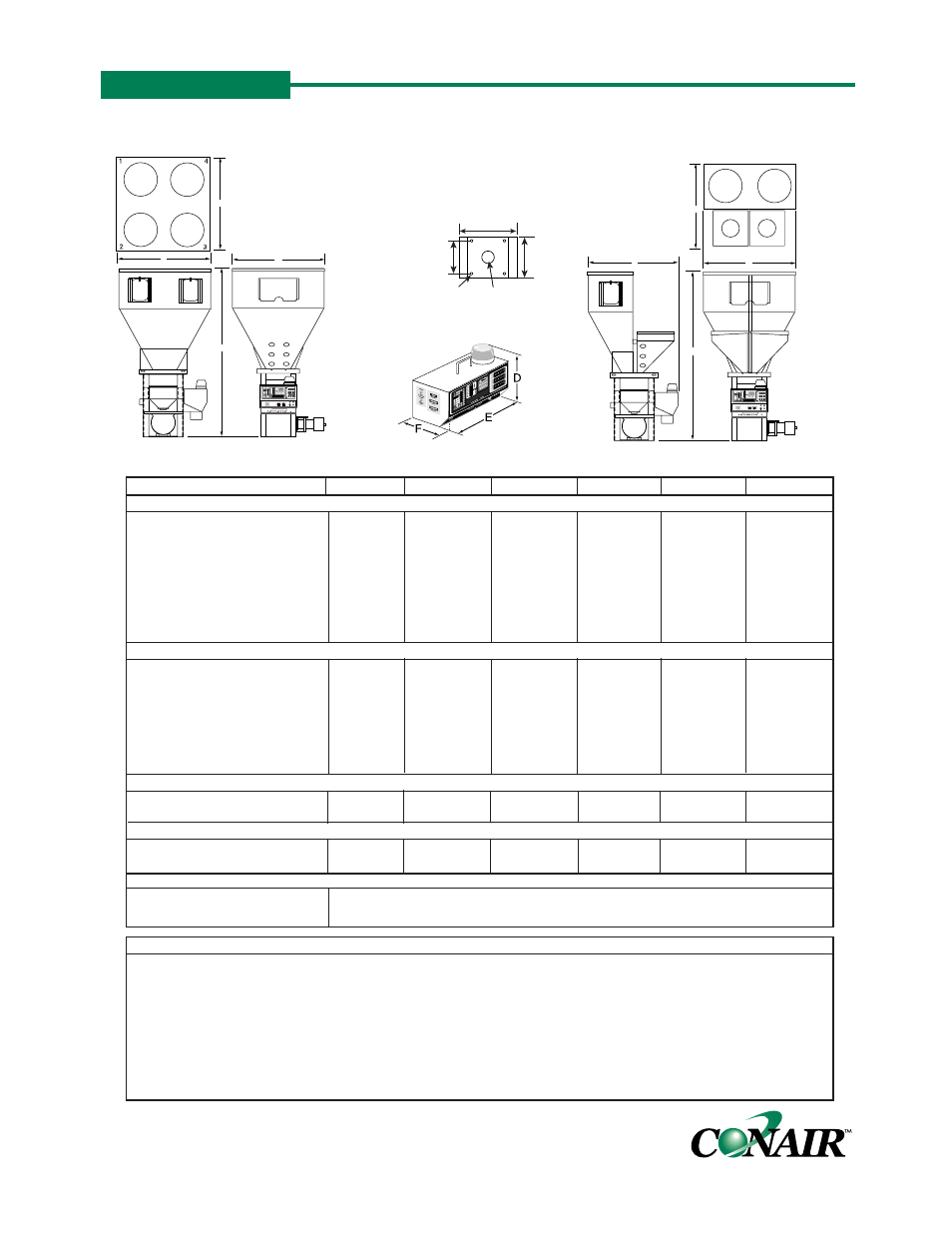

Dimensions inches {mm}

A - Height above mounting plate

†

59.75 {1517.5}

59.75 {1517.5}

59.75 {1517.5}

65.75 {1669.9}

65.75 {1669.9}

65.75 {1669.9}

B - Width

‡

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

C - Width R (removable bins)

‡

32.2 {817.9}

32.2 {817.9}

32.2 {817.9}

32.2 {817.9}

32.2 {817.9}

32.2 {817.9}

D - Depth

‡

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

34.4 {873.8}

E - Controller height

11.25 {285.75}

11.25 {285.75}

11.25 {285.75}

11.25 {285.75}

11.25 {285.75}

11.25 {285.75}

F - Controller width

12.25 {311.15}

12.25 {311.15}

12.25 {311.15}

12.25 {311.15}

12.25 {311.15}

12.25 {311.15}

G - Controller depth

8.19 {208.03}

8.19 {208.03}

8.19 {208.03}

8.19 {208.03}

8.19 {208.03}

8.19 {208.03}

Weight lbs {kg}

Installed

230 {104}

270 {122}

310 {140}

255 {116}

295 {134}

335 {152}

Shipping

335 {152}

375 {170}

415 {188}

360 {163}

400 {181}

440 {200}

Voltage Total amps

§

120V/1 phase/50-60 Hz

4.8

4.8

4.8

4.8

4.8

4.8

240V/1 phase/50-60 Hz

2.5

2.5

2.5

2.5

2.5

2.5

Compressed air requirements

Discharge valves

80 psi @ 0.2 ft

3

/min. {5.5bars @ 0.09 liters/sec}, 1/4 in. NPT fitting

Compressed air feeder

40 psi @ 2 ft

3

/min. {2.8bars @ 0.94 liters/sec}, 1/4 in. NPT fitting

GRAVIMETRIC BATCH BLENDERS

WSB 240/440 and 240/440R Models

SPECIFICATION NOTES:

R models have removable bins. The removable bins can support 8-inch loaders. Stationary bin compartments can support 12-inch to 15-inch

loaders.

* Throughput rates are based on using the F03 auger feeder dispensing no more than 2% per additive or colorant. Maximum throughput rates

for R models are: WSB240R with no feeders 864 lb/hr; with one feeder 619 lb/hr; with two feeders 483 lb/hr. For WSB440R model with no

feeder 1326 lb/hr; with one feeder, 864 lb/hr; with two feeders 640 lb/hr.

† The optional butterfly flow control valve adds 3.5 in. {88.9 mm} to the total height. We recommend using the flow control valve when mounting

the blender to a stand, surge bin or hopper.

‡ Feeders will increase width and depth dimensions. Please refer to feeder specifications.

§

Each auger feeder requires an additional 1 amp @ 120V or 0.5 amp @ 240V.

SPECIFICATIONS

TPBS003/1199

0

0

0

0

0

0

0

0

0

A

B

D

D

Top View

Front View

Side View

0

0

0

0

0

0

0

0

0

A

C

D

C

Top View, R Models

Front View, R Models

Side View, R Models

4

3

2

1

CONTROL

(4) 9/16 in.

{14.3 mm}

diameter

bolt holes

3 in. {76.2 mm}

diameter

through hole

8 in. {203.2 mm}

square bolt pattern

10 in.

{254 mm}

14 in.

{355.6 mm}

IB04

MOUNTING INTERFACE

APPENDIX B