VACUUBRAND RC 5 User Manual

Page 21

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 99 78 31 / 20/12/2006

page 21 of 28

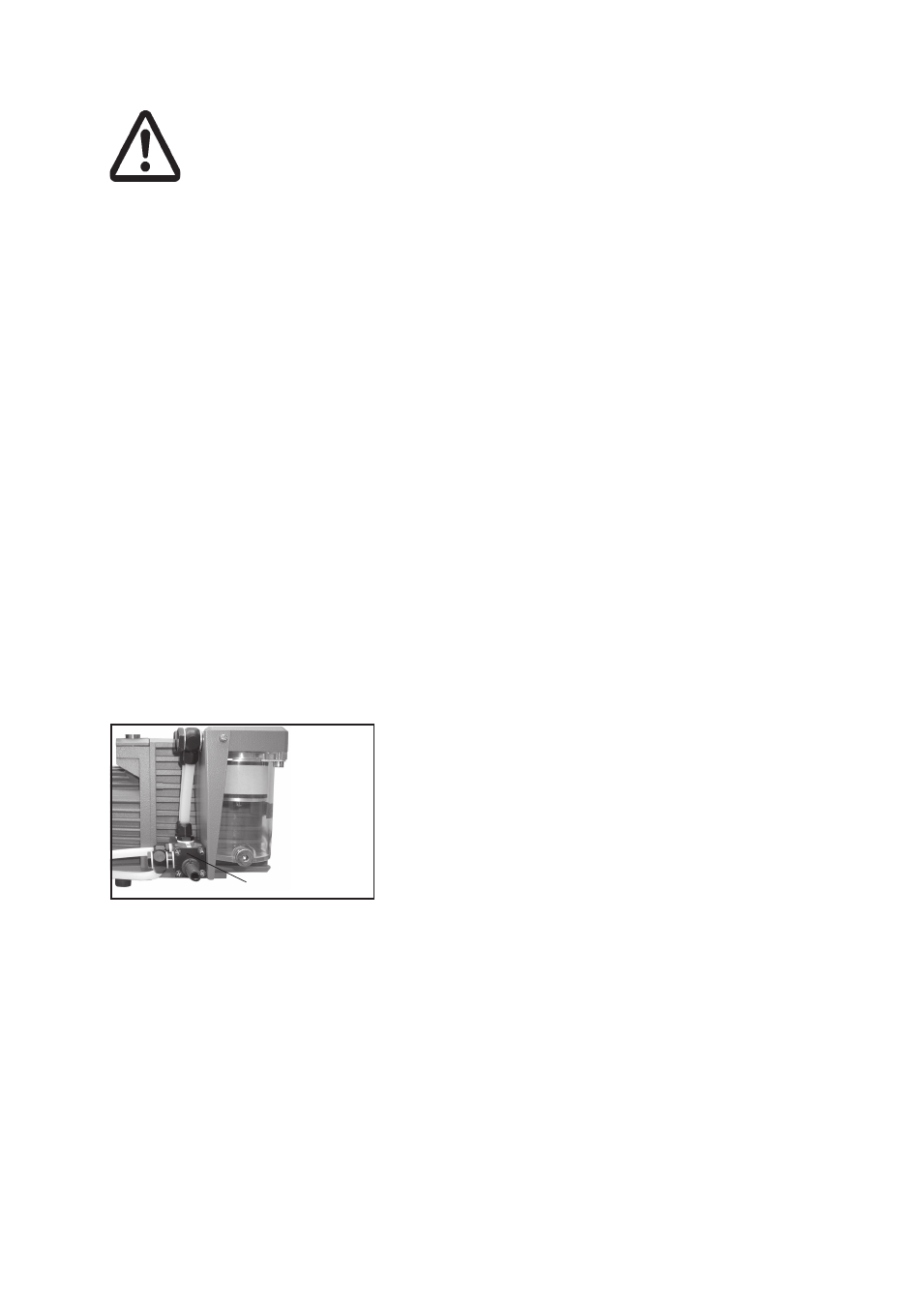

Replacing the filter element in the oil mist filter

➨ Using hex key, remove drain plug (note O-ring fitted on drain plug). Drain conden-

sate from catch pot.

➨ Position pump sideways so that it rests on the side with the mains switch, remove

four socket head securing screws (using w/f 5 hex key) and remove filter catch pot.

➨ Using hex key (w/f 5), remove socket head screw in centre of bottom filter thrust

ring. Remove filter element, filter thrust ring and top seal ring and O-ring.

☞ Clean or replace filter element. Dispose of oil and filter element in accordance with

regulations.

➨ Assembly is the reverse of the disassembly procedure. Make sure that O-ring and

sealing ring are correctly seated.

Inspecting the safety pop valve

➨ Remove four countersunk screws and lift off distributor block.

☞ Note position of valve before removing. Replace valve if

damaged.

➨ Installation of the distributor block is the reverse of the re-

moval procedure

Filter element FO DN 10 ............................................................................................................ 64 01 87

Safety pop valve ........................................................................................................................ 63 88 21

distributor block

If the pump does not achieve the ultimate pressure:

☞ In case the diaphragms and valves have been replaced, a run-in period of several

hours is required before the pump achieves its ultimate vacuum.

If all pump heads achieve a vacuum below 85 mbar but pump does not achieve the

ultimate total pressure:

Check hose connectors between pump heads and manifolds for leaks. If necessary

recheck pump chamber.