Mbar torr hpa – VACUUBRAND MZ 2C VARIO User Manual

Page 17

page 17 of 51

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 999034 / 22/04/2008

In case of excess temperature, the motor is shut down by a thermal cutout in the

winding.

☞ Manual reset is necessary. Switch off the pump or isolate the equipment from mains.

Wait approx. five minutes before restarting the pump. Determine cause of failure

and eliminate.

☞ Attention: In case of supply voltage below 100V, the lock of the cutout might be

restricted and the pump might restart on its own after sufficient cooling down. Take

suitable precautions, if an automatic restart of the pump may lead to a critical

dangerous situation.

How to change the pressure units

+

mbar

Torr

hPa

(mains switch)

Press key p

▲ or p▼ during switching on.

☞ The pressure units are displayed, the pressure unit as from

last operation is flashing.

➨ Press key ▲ or ▼ to change pressure unit. Press key stop

when controller displays the desired pressure unit to finish

the operation mode.

p

Attention: Important notes regarding the use of gas ballast

☞ Make sure that air/gas inlet through the gas ballast valve never lead to hazardous,

explosive or otherwise dangerous mixtures. If in doubt, use inert gas.

☞ When using air rather than inert gas, risk of significant damage to equipment and/or

facilities, risk of personal injury or even loss of life exists due to the formation of

hazardous and/or explosive mixtures if air and pumped media react inside or at the

outlet of the pump.

For condensable vapours (water vapour, solvents, ...):

☞ Do not pump vapour before pump has reached its operating

temperature and with gas ballast valve closed.

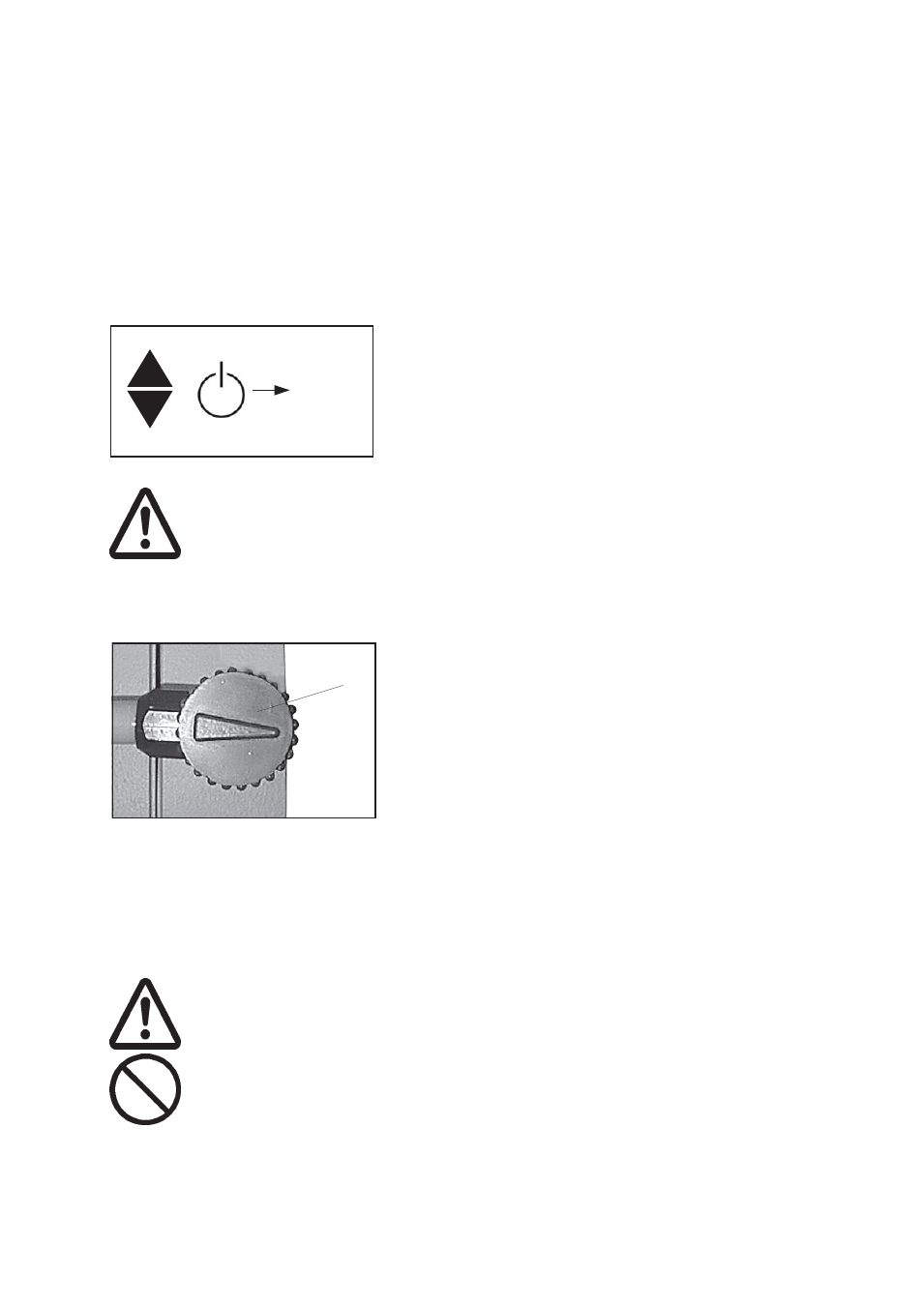

☞ The gas ballast valve is open if the arrow on the gas ballast

cap points away from the pump (MZ 2C VARIO / MD 4C

VARIO / PC 2002 VARIO), respectively downwards (PC 2003

VARIO / PC 2004 VARIO).

☞ The gas ballast valve is open if the arrow on the gas ballast

cap points away from the pump.

☞ With gas ballast valve open ultimate vacuum will be reduced,

pumping speed is decreased.

☞ Use inert gas at the air inlet to avoid the formation of explosive mixtures.

gas

ballast

In case of low boiling solvents when the formation of condensate is unlikely, the use of

gas ballast might be unnecessary.

☞ Operating the pump without gas ballast increases the solvent recovery rates at the

exhaust waste vapour condenser.

Attention: Notes concerning the operation of the exhaust waste vapour condenser

➨ Check hose connections prior to starting operation of the cooling system.

➨ Check coolant hoses regularly during operation.

☞ Ensure that the coolant outlet pipeline is always free and that it cannot get blocked.

☞ Maximum permissible coolant pressure at the exhaust waste vapour condenser:

6 bar (absolute)

☞ Comply with the maximum permissible coolant pressures of additional components

in the coolant circuit (e.g coolant valve).

☞ Avoid overpressure in the coolant circuit (e.g. caused by blocked or squeezed cool-

ant hoses).

☞ Permissible range of coolant temperature at the exhaust waste vapour condenser:

-15°C to +20°C