Lp gas hook-up – Twin Eagles TEPB24-B User Manual

Page 6

3 |

P a g e

It must be provided with a shut-off valve terminating in gas tank valve outlet. It must include a

collar to protect the cylinder valve. The cylinder supply system must be arranged for vapor

withdrawal.

Do not operate the gas Power Burner indoors or in any enclosed area. If the gas Power Burner is

not in use, the gas must be turned off at the supply cylinder. If the Power Burner is to be stored

indoors, disconnect the gas supply cylinder and leave the cylinder outdoors.

LP GAS HOOK-UP

–

T

WIN

E

AGLES

G

AS

P

OWER BURNER

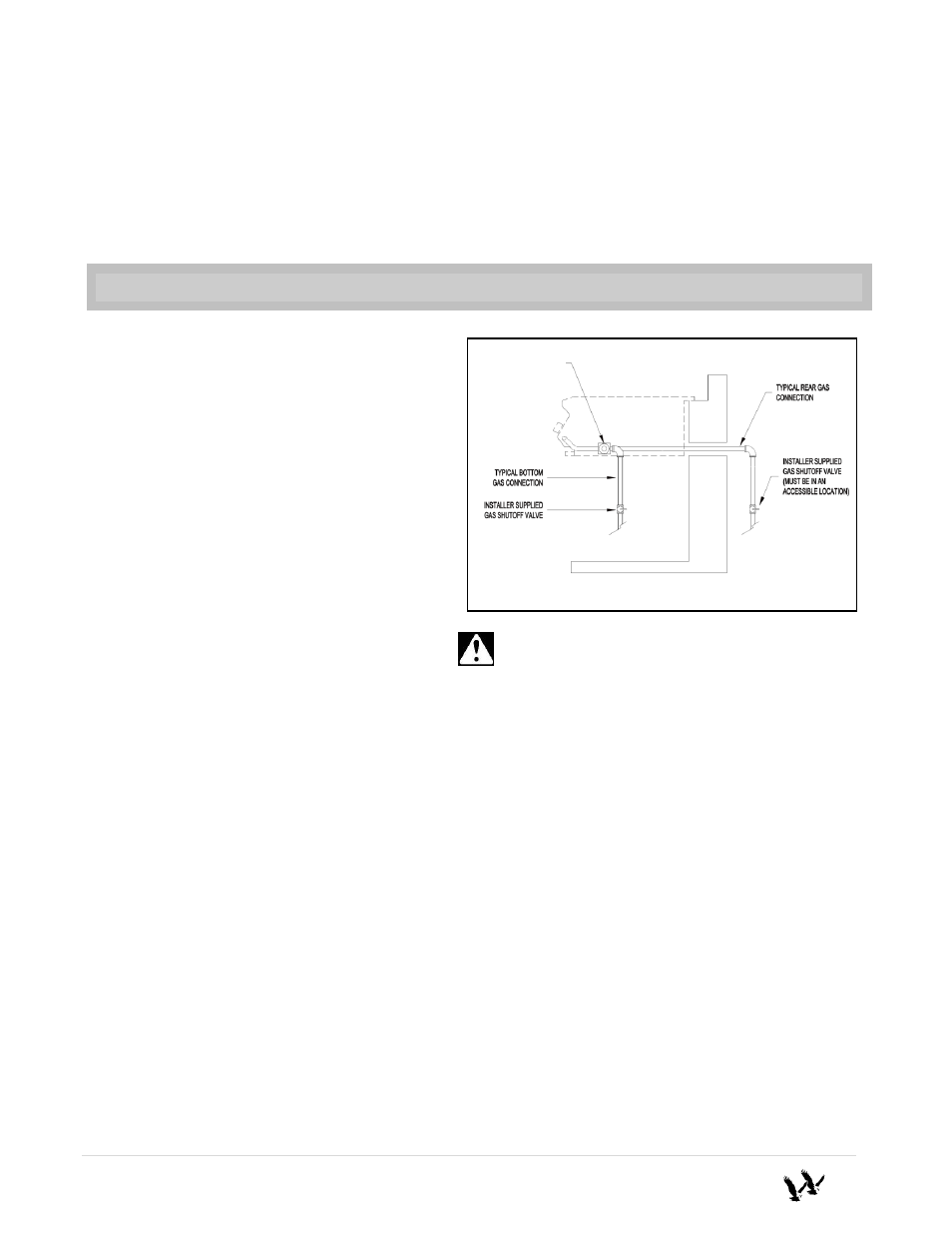

A typical LP gas installation is shown

on the right. Make sure that the factory-

supplied regulator is used and installed with the

arrow mark on the regulator pointing towards

the Power Burner. Do not use any replacement

regulator other than that specified by Twin

Eagles. Use only pipe sealants that are

approved for use with natural and LP gases. An

installer-supplied gas shutoff valve must be

installed in an accessible location.

(Reference:

page 4 for leak test procedure).

Although LP

gas cylinder may be used, it is not

recommended due to the large amount of

gas consumption of the unit and will freeze

up the LP gas cylinde

r.

Note: An enclosure for LP gas cylinder must be vented on the level of the cylinder valve and at floor

level. The effectiveness of the opening(s) for purposes of ventilation shall be determined with the LP

gas supply cylinder in place. This shall be accomplished by one of the following:

a. One side of the enclosure shall be fully open; or

b. For an enclosure having four sides, a top and a bottom:

1. At least two ventilation openings at cylinder valve level shall be provided in the sidewall,

equally sized, spaced at 180 degrees (3.14 rad), and unobstructed. Each opening shall have

a total free area of not less than 1/2 square inch per pound (7.1 cm

2

/kg) of stored fuel

capacity and not less than a total free area of 10 square inches (64.5 cm

2

).

Ventilation opening(s) shall be provided at floor level and shall have a total free area of not

less than ½" square inch per pound (7.1 cm2/kg) of stored fuel capacity and not less than a total free

area of 10 square inches (64.5 cm2). If ventilation openings at floor level are in a sidewall, there shall

be at least two openings. The bottom of the openings shall be at floor level and the upper edge no more

than 5 inches (127 mm) above the floor. The openings shall be equally sized, spaced at 180 degrees

(3.14 rad) and unobstructed.

CAUTION: Provide adequate ventilation holes in the

enclosure for safety purposes in the event of a gas leak.

TYPICAL GAS HOOK UP

REGULATOR SET

AT 10” WC (LP GAS)

OR 4” WC (NG GAS)