Solberg Scrubbers User Manual

Page 4

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Ph: 630.773.1363 Fax: 630.773.0727 Email: [email protected] Web: www.solbergmfg.com

Rev: MM Scrubbers May 2010

Page 4

SOLBERG

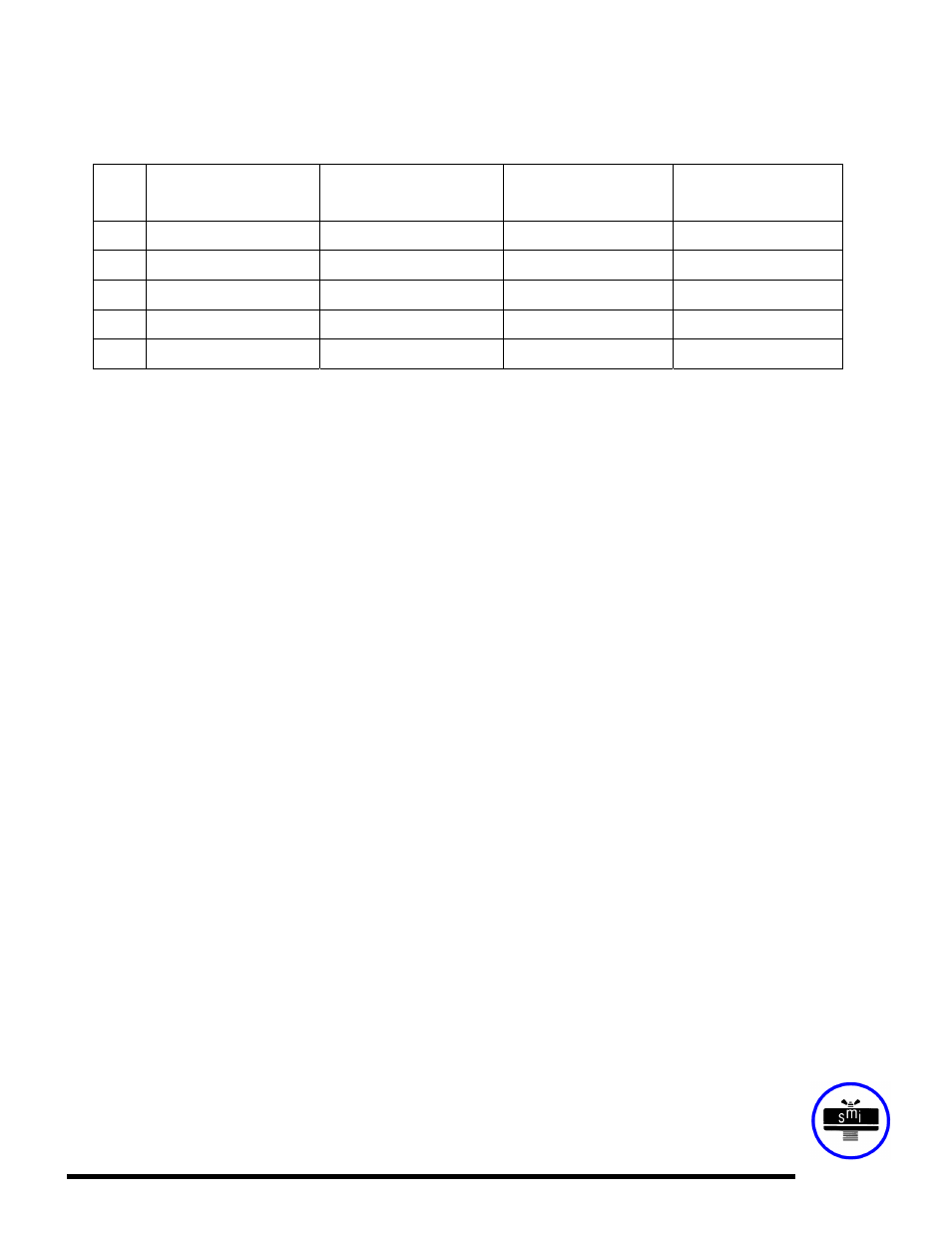

Record the actual nameplate data from your new Solberg scrubber/separator vessel(s):

No.

Assembly Model

Number

Replacement

Element

Vane

Pack

Demister

Pack

1

2

3

4

5

Table 1

2. Filtration Rules of Thumb

General: To ensure peak performance and delivered output from a compressor, blower,

turbine or engine, there must be clean and minimally restricted air/gas flow into the

equipment out of the equipment. Proper scrubber/separator filtration will eliminate

particulate, condensate and hydrocarbon mist from air/gas streams under extreme

conditions. Filter size is a critical component to minimizing restriction and maintaining

ideal operating conditions. With a properly sized filter, equipment will run efficiently

over its operating life.

A primary factor in filtration efficiency and size is air velocity through the filter media.

Generally, when velocity through a media is minimized, the filtration

efficiency is

maximized. In this scenario, pressure differential/restriction across the filter is also

minimized. The primary objective when sizing a filter is to optimize the velocity of air

through the media (sometimes called face velocity).

Solberg’s filter designs are completed after analyzing and interpreting the Operators’

application specifications and requirements.

3. Filter Element Specifications

Media: CEG, PSG

Efficiency: 99.97% @ 0.3 micron

Typical Element Operating Differential Pressure: 0 – 5 psig / 0 – 0.36 BAR

Filter Change-Out Differential: 2.5 psid / 0.17 BAR over initial backpressure of the

saturated element

Typically used in oil mist coalescer/separator applications