Solberg BBF Assembly User Manual

Page 8

8

“BBF” Series Blower Base Frame Assembly Instructions Rev.: 9105

SOLBERG

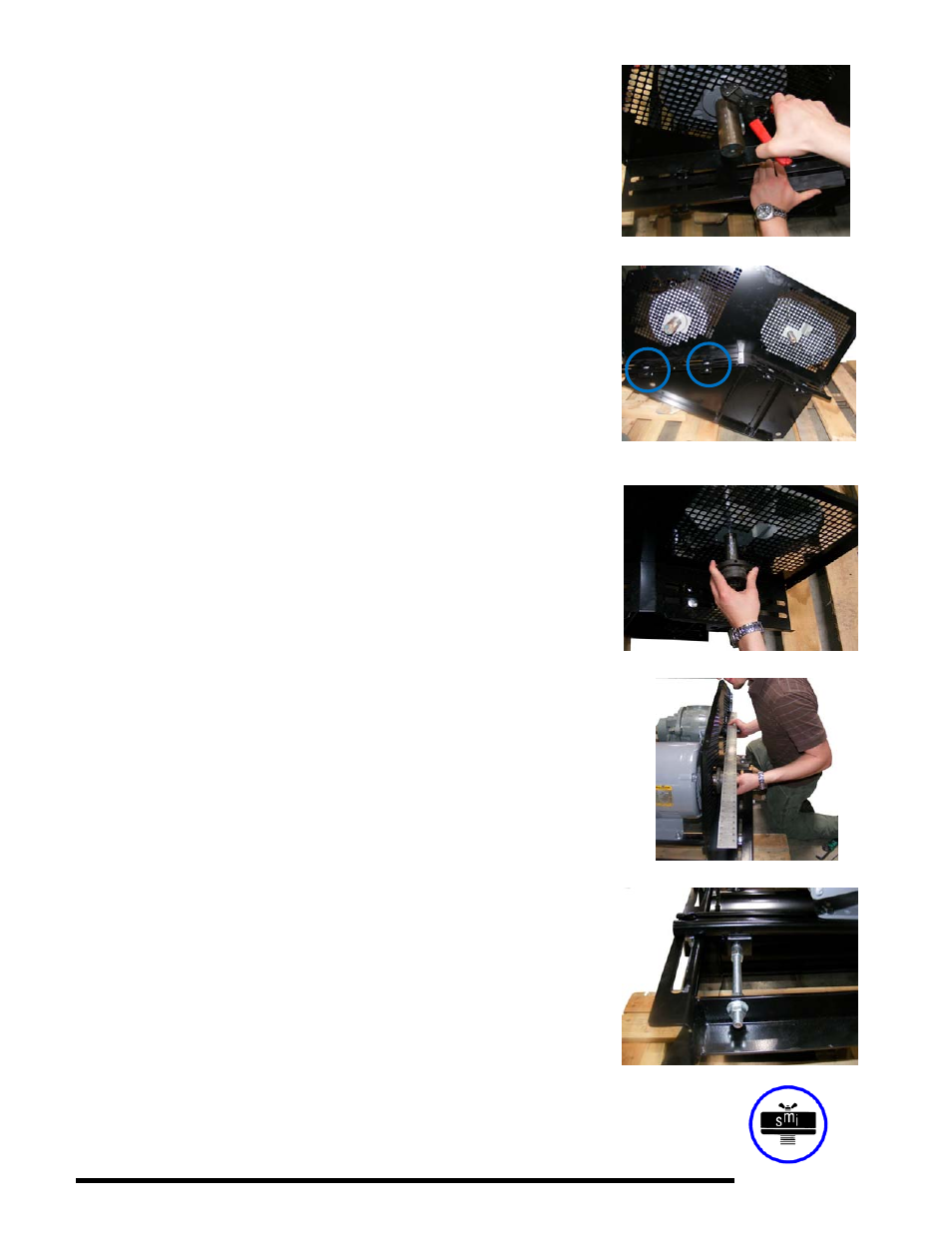

10.4 Remove only enough material to allow the drive shafts to freely

pass through and accommodate any adjustments needed when

tensioning the belts. Attach the belt guard to the channels. The

belt guard should sit on all (4) channels.

10.5 Individually place a carriage bolt, (4) total through the slot in the

bottom of the belt guard and through the slot in the channel.

Loosely tighten a flange nut on each carriage bolt; the channels

will need to slide in the slot in the belt guard during tensioning.

10.6 The grid material can be removed by using compact bolt/wire

cutters (aviation snips, diagonal cutting pliers etc.) or grinder. Use

caution and eliminate any hazardous sharp edges prior to final

installation.

11.1 MN - (1) Motor shaft bushing

- (1) Blower shaft bushing

- (1) Motor sheave

- (1) Blower sheave

11.2 TN - Allen wrenches

11.3 Follow the bushing and sheave manufacturer’s instructions

for assembling the bushing and sheave on the motor and

blower shafts. Follow the manufacturer’s instructions for

bushing and sheave placement on shaft to reduce bearing

wear.

11.4 Set and begin aligning sheaves. Most manufacturers recommend

no more than 1/8” to 1/4” gap between sheave face and blower or

motor face. Consult the manufacturer’s specifications.

12.1 MN - Drive belts

- (4) 1/2”-13 x 1-1/2” carriage bolts

- (4) ½”-13 “whiz” flange nuts

12.2 TN - Tension measurement device

- Straight edge

12.3 Loosen nuts on motor channels from BBF. Slide motor on

channels towards the blower. Individually place the drive belts

around each sheave in its’ respective groove. Slide the motor on

channels away from the blower to remove the slack from the drive

belts.

Figure 10.4

Figure 10.5

Figure 11.3

Figure 11.4

Figure 12.3