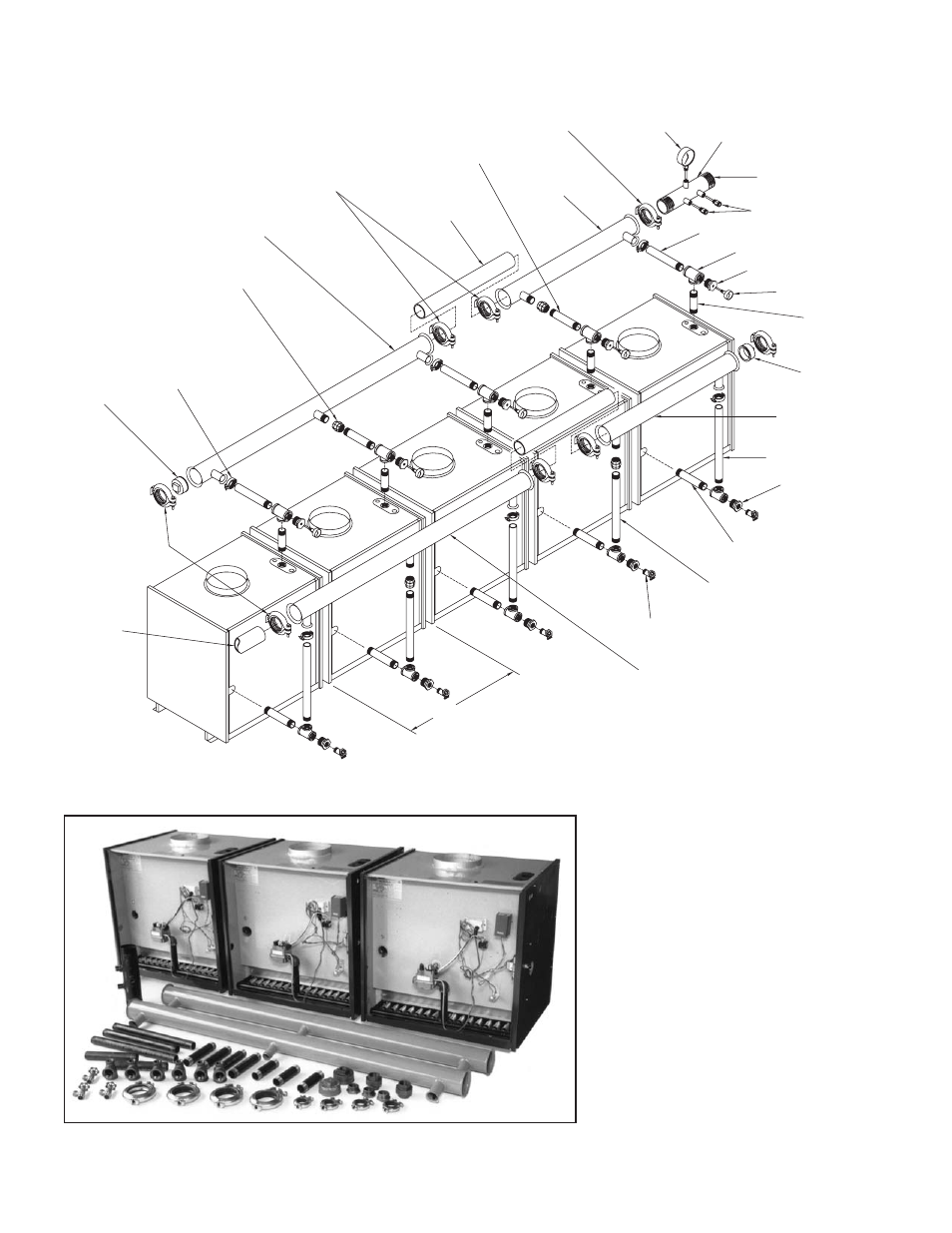

Factory supply and return header assembly — gas, Complete header assembly kit shown for 3 modules – Slant/Fin G-Series User Manual

Page 2

• Building piping must be rigidly

secured so it cannot move

where connected to headers.

NOTE:

Shown reverse return. For direct

return, header assembly piping

connections may be made at the

same end of the boiler bank, not

as shown.

Some governing agencies do not

allow compression type couplings.

Consult your local code

requirements.

FACTORY SUPPLY AND RETURN HEADER ASSEMBLY — GAS

Complete header assembly kit shown for 3 modules.

CAST END CAP

1-1/2” FLEX JOINT

(SEE DETAIL “A”)

SUPPLY HEADER

WITH THREE 1-1/2” STUBS

1-1/2” UNION

3” FLEX JOINTS

(SEE DETAIL “A”)

1-1/2” NIPPLE 8”

SUPPLY HEADER

WITH TWO

1-1/2” STUBS

3” FLEX JOINT

(SEE DETAIL “A)

1/2” TRIDICATOR

GAUGE

CONTROL HEADER

3” x 1/2” x 1/2” x 1/2”

3” BUILDING PIPING

CONNECTION

1/2” WELLS

1-1/2” SQUARE NIPPLE x 10”

1-1/2” TEE

1-1/2” x 1/4” BUSHING

TRIDICATOR

1-1/2” NIPPLE x 4”

CAST END CAP

WITH 3/4” TAPPING

RETURN HEADER

WITH TWO 1-1/2” STUBS

1-1/2” SQUARE NIPPLE x 20”

1-1/2” x 3/4” BUSHING

1-1/2” NIPPLE x 18”

3/4” DRAIN VALVE

(BY OTHERS)

1-1/2” NIPPLE x 8”

RETURN HEADER

WITH THREE 1-1/2” STUBS

* 3” BUILDING PIPING

(BY OTHERS)

3” PIPE x 28”

TYPICAL

(BY OTHERS)

32” TYP.