Venting a oil-fired system – Slant/Fin Oil Hot Water User Manual

Page 10

10

VENTING A OIL-FIRED SYSTEM

A boiler venting system provides draft and an escape path for the

products of combustion. In a venting system for an oil-fired

Caravan, there are three major components: a riser with draft reg-

ulator for each module, a breeching manifold, and a chimney.

Sometimes the venting system for a boiler plant has to be

designed to compensate for inadequate chimney conditions. A

mechanical draft inducer, properly sized and installed, can usually

increase chimney capacity sufficiently to provide proper venting.

Where a draft inducer is called for, consult local codes and the

recommendations of the mechanical draft inducer manufacturer.

Normally, a draft proving device is necessary to permit operation

of the boilers only when adequate draft exists.

It is important to note that when considering a mechanical draft

inducer, the boiler room air supply requirements must be

increased. Consult the draft inducer manufacturer for this

information.

Draft Regulator

The draft regulator compensates for excessive draft that can be

caused by varying weather conditions. The regulator should be of

the barometric-draft type. Once adjusted for a particular venting

system, this type regulator automatically compensates for

excessive draft to assure optimum operating efficiency.

Breeching

Breeching is a term used to describe a manifold(s) that connects

individual boiler modules to a chimney. Breeching is usually

constructed of sheet metal having a smooth interior surface with

all joints made tight against leakage. The layout of a particular

boiler room may require that the modules be arranged in

"batteries" with rows either parallel or at right angles. Minimum

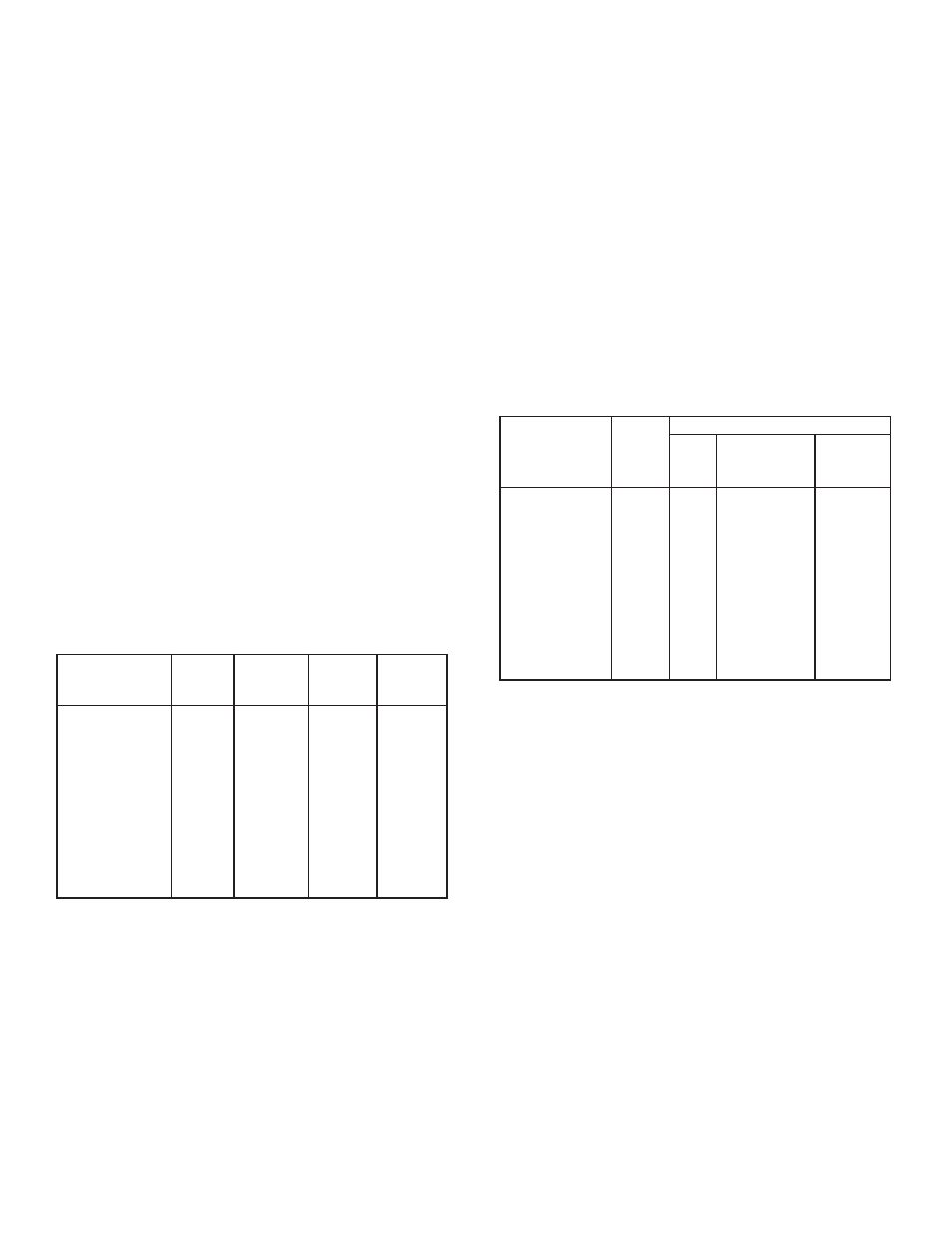

breeching sizes are given in Table 3.

To avoid creating turbulent air patterns in the breeching, it is

suggested that individual boiler vent pipes be connected to the

breeching as indicated in Figure 13.

The breeching manifold should extend into, but not beyond, the

chimney liner. Round breeching is preferable to rectangular

breeching.

Chimney

Caravan oil-fired modular boilers operate efficiently with masonry

or prefabricated chimneys. This latter type of chimney construction

is generally the least expensive.

Minimum chimney sizes and heights are given in Table 4. In

addition, the chimney should be high enough to minimize the

effects of turbulent winds and high pressure areas common near

roof-top obstructions. The National Board of Fire Underwriters

recommends that the chimney should extend 3 feet above the roof

and be 2 feet higher than any obstruction within 10 feet (figure

13). The use of a vent cap where permitted by code gives addi-

tional protection against adverse wind conditions and precipitation.

Sizing Horizontal Breeching Connectors and Chimneys for

Oil-Fired Systems

Horizontal breeching connectors shall be constant sized. The

chimney and the horizontal breeching connector are sized using

table 3.

When there are multiple banks of boilers, the horizontal breeching

connector for each bank is sized using table 3. To size the com-

mon horizontal breeching connector, add up the total input and

refer to table 3 to size.

The minimum chimney will be equal to the size of the largest hori-

zonatl breeching section connected to it.

LDWO-600-2-5

2

11"

84

4'8"

LDWO-750-2-6

2

12"

101

4'8"

LDWO-850-2-7

2

13"

115

4'8"

LDWO-900-3-5

3

13"

123

7'1"

LDWO-1100-3-6

3

14"

148

7'1"

LDWO-1300-3-7

3

15"

170

7'1"

LDWO-1700-4-7

4

16"

189

9'6"

LDWO-2100-5-7

5

18"

233

11'11"

LDWO-2500-6-7

6

19"

277

14'4"

LDWO-2900-7-7

7

21"

320

16'9"

LDWO-3400-8-7

8

22"

365

19'2"

Model No. *

No. of

Modules

Breeching

Diameter

Minimum

Area

(sq.in.)

Breeching

Length

*

Dual fuel prefix = LWDF.

Notes:

1. For breeching and chimney sizing over 8 modules, consult factory.

2. Breeching length should be as short as possible. Measurement from the

base of the vertical vent to the nearest connected appliance should be

limited to 10' or 50% of the total vent height, whichever is greater.

Table 3. Breeching dimensions for oil-fired systems —

LDWO Series

LDWO-600-2-5

2

11"

9

3

⁄

4

" X 9

3

⁄

4

"

20'

LDWO-750-2-6

2

12"

9

1

⁄

2

" X 13

1

⁄

2

"

20'

LDWO-850-2-7

2

13"

13

1

⁄

4

" X 13

1

⁄

4

"

20'

LDWO-900-3-5

3

13"

13

1

⁄

4

" X 13

1

⁄

4

"

20'

LDWO-1100-3-6

3

14"

13

1

⁄

4

" X 13

1

⁄

4

"

20'

LDWO-1300-3-7

3

15"

13" X 17"

20'

LDWO-1700-4-7

4

16"

13" X 17"

25'

LDWO-2100-5-7

5

18"

16

3

⁄

4

" X 16

3

⁄

4

"

25'

LDWO-2500-6-7

6

19"

16

1

⁄

2

" X 20

1

⁄

2

"

25'

LDWO-2900-7-7

7

21"

20

1

⁄

4

" X 20

1

⁄

4

"

25'

LDWO-3400-8-7

8

22"

20

1

⁄

4

" X 20

1

⁄

4

"

25'

Model No. *

No. of

Modules

Dia.

Inches

Rectangular

L x W

Inches

Minimum

Height

Feet

Chimney Liner Inside Dim. †

*

Dual fuel prefix = LWDF.

† Dimensions shown are from ASHRAE Guide Equipment Handbook. Also

select inside liner dimensions to give area as great or greater than shown in

this table. Chimney height is measured from the center line of the breeching

to the top of the chimney. Chimney dimensions are approximate, with no

manifold elbows or tees; and good vent construction practices. Field

conditions vary. It is doubtful that the chimney dimensions shown here will

be suitable for all applications. Consult the 2000 ASHRAE Equipment

Handbook and Chimney Manufacturers Sizing Handbook.

Table 4. Chimney requirements