PS Engineering PM1000 User Manual

Page 3

PS Engineering Incorporated

PM 1000 FAA TSO Approved Intercom

Installation and Operation Manual

200-190-0002

5

Rev. 2, Jan. 2001

Section II Installation

2.1 General Information

The PM1000 comes with all mounting hardware for installation. A 2-place jack kit is available, part number

250-000-0040.

Installation of the PM1000, using the hardware supplied and available wiring, does not require special tools

or knowledge other than described in FAA Advisory Circular 43.13-2. It is the installer's responsibility to

determine the approval basis for this installation. An FAA Form 337, or other approval may be required. See

Appendix B for example of FAA Form 337.

2.2 Unpacking and preliminary inspection

The PM1000 was carefully inspected mechanically and thoroughly tested electronically before shipment. It

should be free of electrical or cosmetic defect.

Upon receipt, verify that the parts kit (p/n 250-001-0001) includes the following:

Part Number

Description

Quantity

475-440-0318

#4-40 Machine screws, black

2

625-001-0002

Concentric inner knobs

2

001-001-0002

Outer knobs w pointer

2

430-001-0003

Aluminum doubler plate

1

425-025-0002

25 pin Sub-d male connector

1

425-025-0003

Connector hood

1

475-002-0000

Connector Thumbscrews

2

575-001-0001

PM1000 label set

1

200-190-0001

Operator's and Installation Manual

1

122-001-0000

Drill Template

1

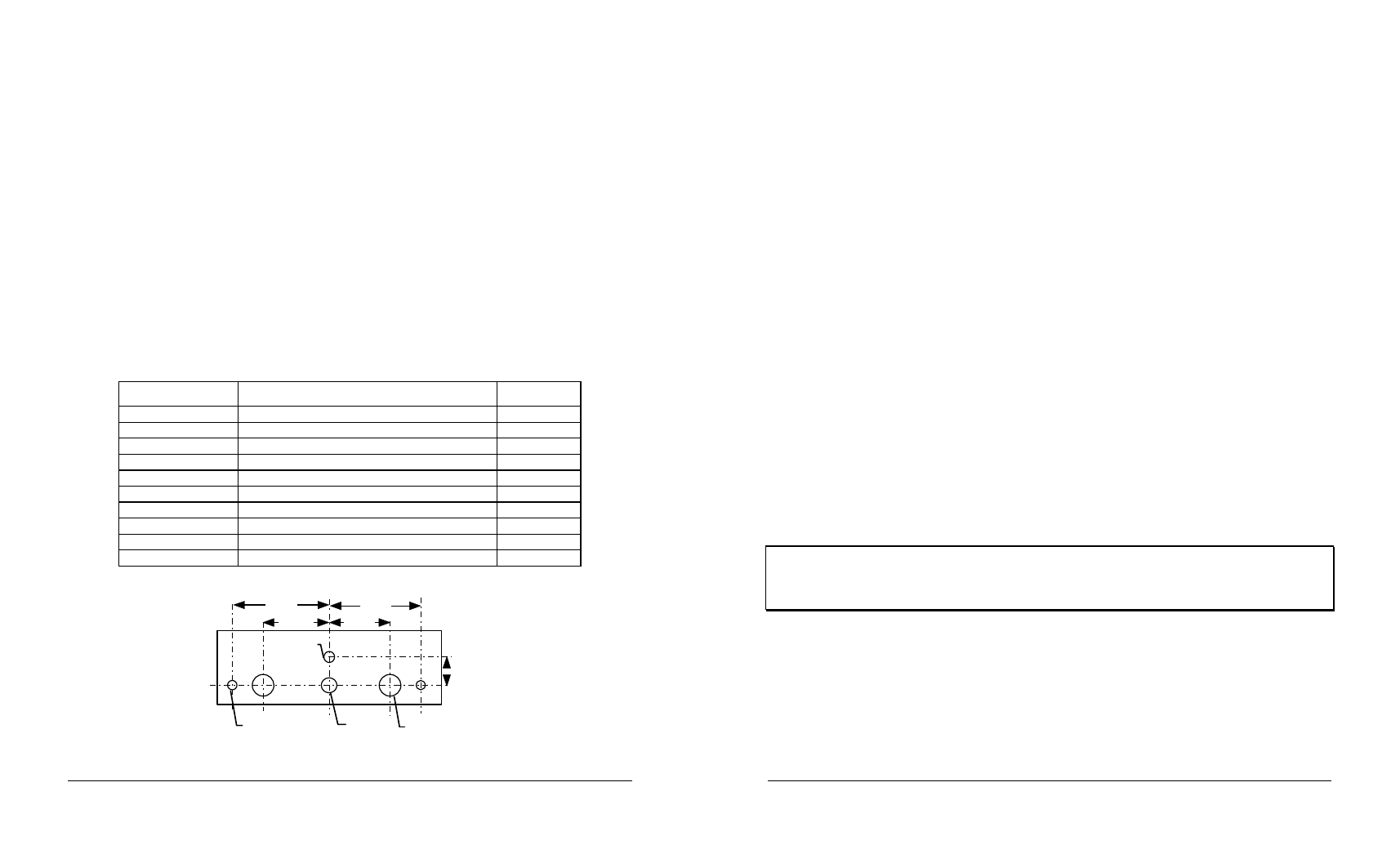

2.3 Equipment installation procedures

0.250

2 ea. 0.125

0.265

2 ea. 0.406

1.200

1.200

0.838

0.838

0.325

NOT TO SCALE

Figure 2-1 Hole Spacing

PS Engineering Incorporated

PM 1000 FAA TSO Approved Intercom

Installation and Operation Manual

200-190-0002

6

Rev. 2, Jan. 2001

1. Using the template, drill six holes in the instrument panel in a location convenient to the pilot

position(s).

2. Insert the PM1000 from behind the instrument panel, aligning the holes for the knobs, LED, and switch.

3. Depending on the instrument panel thickness (<0.040”), you may elect to use the aluminum faceplate to

provide additional support. Place the aluminum plate over the knob shafts and secure, using the two # 4-

40 round head screws provided.

4. Remove the backing from either the horizontal or vertical graphics label provided with the unit, carefully

align over the knob shafts, and press firmly in place.

5. Install the knobs over the volume and squelch control shafts.

2.4 Cable harness wiring

To complete the installation, a wire harness must be made as shown in Appendix D.

PS Engineering can make a custom-tailored wiring harness for the installer. All harnesses use Mil-spec

quality components with professional techniques, and are fully tested before shipment. Contact PS

Engineering for more information.

If the aircraft already has pilot and copilot headset jacks installed, you may re-use them. Remove and discard

all wires from the copilot headset jacks. You may use the existing pilot headset jacks as the Auxiliary Aircraft

Radio Headset Jacks, but they should be moved to a new location to avoid confusion with the pilot's

headphone jacks. In the event the intercom has to be removed for any reason, these jacks provide access to the

aircraft radio system.

To connect intercom into the aircraft audio system, parallel the appropriate set of cables from the intercom to

the Auxiliary Aircraft Radio Headset Jacks. Finally, install new headset jacks into the aircraft and connect

them directly to the appropriate pins of the PM1000. See the wiring diagram for all details of the wire

harness interconnects.

2.4.1 Electrical Noise Issues

WARNING: You must use separate shielded cables for the microphone and headphone jacks. Combining

these two wires WILL cause loud oscillations and degrade the intercom function. The oscillation is caused by

the cross-coupling between the large headphone signal and the small microphone signal. The resulting

feedback is a high-pitched squeal that varies with the volume controls.

Due to the variety of the radio equipment found in today's general aviation aircraft, there is the potential of

both radiated and conducted noise interference. The PM1000 has a specially designed power supply to reduce

conducted electrical noise on the power bus of the aircraft by at least 50dB. Although this is a very large

amount of attenuation, it does not eliminate all noise when the amount is excessive. There must be at least

13.75 Volts DC present at the PM1000 for the power supply to work within its designed regulation.

Otherwise, it will not be able to attenuate noise properly.

Shielding can protect the system from radiated noise (rotating beacon, electric gyros, switching power

supplies, etc.). However, installation combinations can occur where minor interference is possible. The