Installation of silencer and adaptors – O.S. Engines 120AX User Manual

Page 9

16

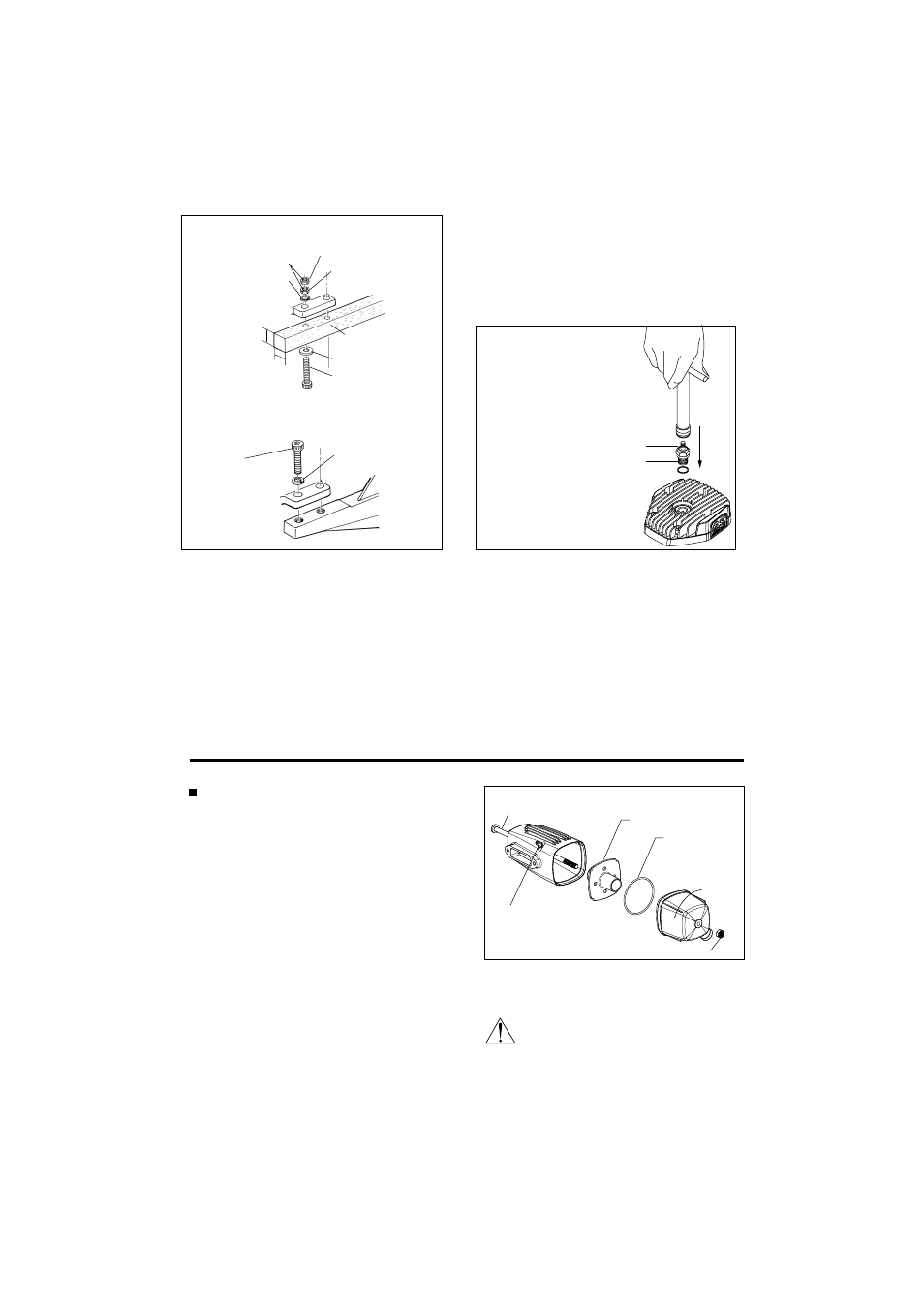

Make sure that these mounting beams are

accurately aligned and firmly integrated with

the airframe, reinforcing the adjacent

structure to absorb vibration. Use 4mm or

larger steel screws, preferably Allen type

hexagon socket head cap screws, with

washers and locknuts, for bolting the engine

to the bearers.

How to fasten the mounting screws.

Hardwood mounting beams

Radial motor mount

(cast aluminum)

Tighten second nut

firmlydown onto first nut.

Tighten this nut first.

Steel washer

4mm steel nuts

4mm steel screw

Spring washer or

lock washer

15mm min.

15mm min.

Hardwood such as

cherry or maple.

Spring washer

4-5mm

steel Allen screw

INSTALLING THE GLOWPLUG

Install washer on glowplug and

insert carefully into cylinder-head,

making sure that it is not cross-

threaded before tightening firmly.

Glow plug

Washer

17

The exhaust outlet of the silencer can be

rotated by 90 degrees the following manner:

Loosen the locknut and assembly screw.

Set the exhaust outlet at the required posi-

tion by rotating the rear part of the silencer.

Re-tighten the assembly screw, followed by

the locknut.

1)

2)

3)

Assembly screw

Locknut

Exhaust pressure nipple

Model engines generate considerable

heat. Do not touch any part of your

engine until it has cooled. Contact

with the muffler (silencer), cylinder

head or exhaust header pipe, in

particular, may result in a serious

burn. Keep your hands and face away

from exhaust gas or you will suffer a

burn.

Reminder!

Secure the silencer to the engine by means of

two retaining screws supplied after the engine

is securely mounted to a test bench or a

model.

It is recommended to seal the fitting faces of

engine exhaust and silencer with silicone

sealant.

Gasket

INSTALLATION OF SILENCER AND ADAPTORS

E-5020

Baffle plate

Can be rotated

by 90 degrees.