Mixture controls – O.S. Engines 120AX User Manual

Page 13

24

Note:

Some spinners without a removable nose

cone cannot be used with the prop locknut

supplied with the engine. In this case,

optional locknut sets are available from

O.S. – Propeller Locknut Set for Spinner

(Code No.45910200) and Propeller Locknut

Set for 4C Spinner (Code No.45910300).

IMPORTANT

Regardless of the type of propeller used,

make a habit of always checking the

tightness before starting the engine.

Remember that, especially with wooden

propellers, there is a tendency for the

material to shrink, or for it to be reduced by

the serrated face of the drive hub.

25

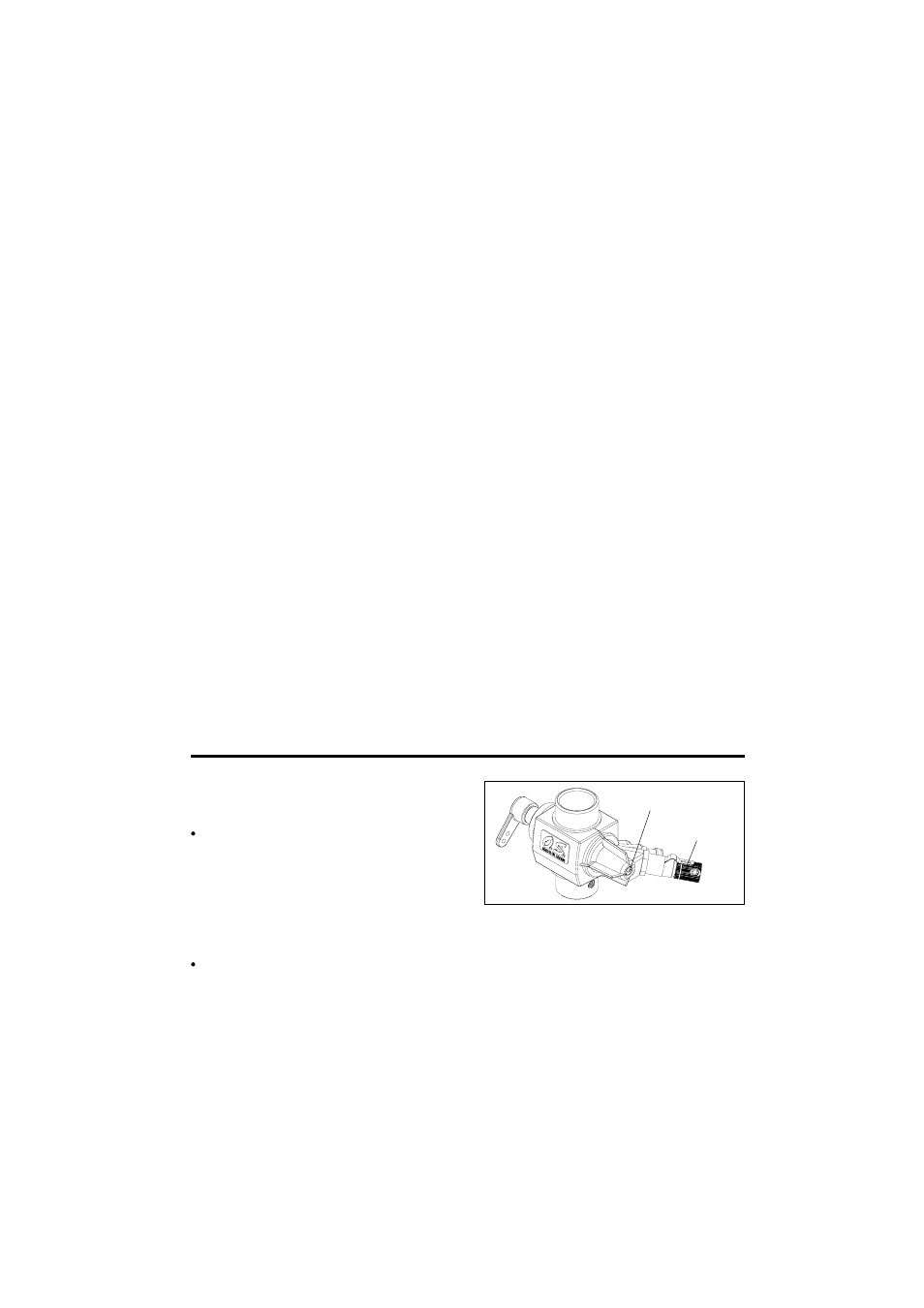

MIXTURE CONTROLS

The Needle Valve

When set to produce maximum power at full

throttle, this establishes the basic fuel/air

mixture strength. The correct mixture is then

maintained by the carburetor's built-in

automatic mixture control system to cover

the engine's requirements at reduced throttle

settings.

The Mixture Control Valve

This meters fuel flow at part-throttle and

idling speeds to ensure reliable operation as

the throttle is opened and closed. The

Mixture Control Valve is factory set for the

approximate best result. First run the engine as

received and readjust the Mixture Control Screw

only if necessary.

Two mixture controls are provided on this

Carburetor.

Needle Valve

Mixture Control Valve

Mixture Control Valve of the carburetor is set

at basic position ( a little on the rich side) at the

factory. However, minor readjustment will be

required for a fuel used, atmospheric

conditions and a model. When a good result is

not obtained with the factory setting, readjust it

according to the MIXTURE CONTROL VALVE

ADJUSTMENT section. Please note during a

running-in period flights should be made with a

slightly rich needle setting. Therefore, during a

running-in period proper carburetor responses

will not be obtained. Adjust it at optimum

position after the running-in is completed.