Throttle linkage, Needle-valve extension, Propeller & spinner attachment – O.S. Engines 120AX User Manual

Page 12

22

THROTTLE LINKAGE

Before connecting the throttle to its servo,

make sure that the throttle arm and linkage

safely clear any adjacent part of the airframe

structure, etc., as the throttle is opened and

closed. Connect the linkage so that the throttle

is fully closed when the transmitter throttle

stick and its trim lever are at their lowest

settings and fully open when the throttle stick

is in its fully-open position. Carefully align the

appropriate holes in the throttle arm and servo

horn so that they move symmetrically and

smoothly through their full travel.

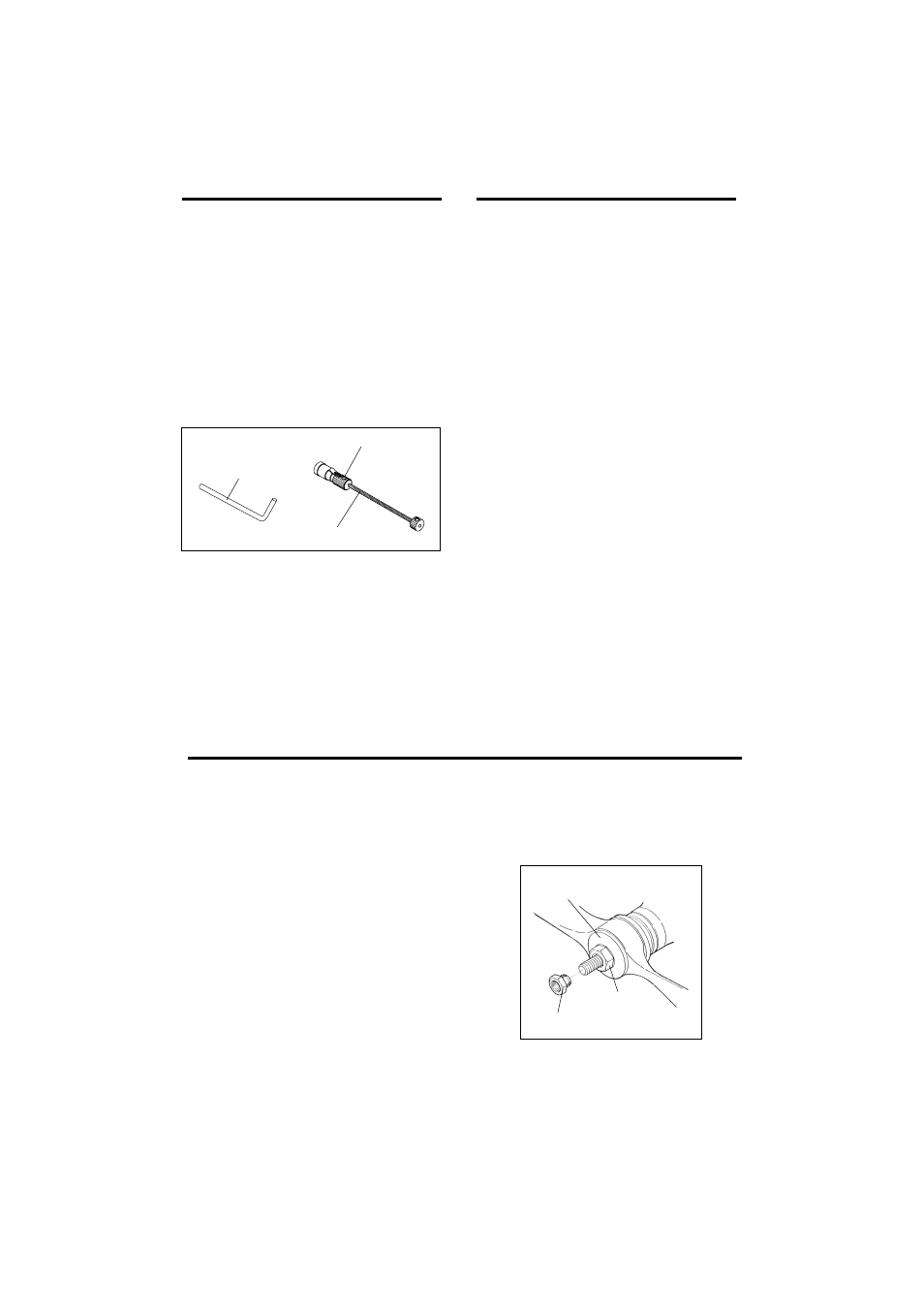

NEEDLE-VALVE EXTENSION

The needle-valve supplied with this engine is

designed to incorporate an extension so that,

when the engine is enclosed within the

fuselage, the needle-valve may be adjusted

from the outside. For this purpose, Needle

Valve Extension Cable Set is supplied with the

engine. If a longer extension is reguired, cut a

commercially available rod to the required

length, bend one end to an L shape, insert it

into needle's center hole and secure it by

tightening the set-screw in the needle-valve

knob with 1.5mm Allen key.

Needle Valve Extension Cable Set

1.5mm Allen key.

Set Screw

23

PROPELLER & SPINNER ATTACHMENT

There is a risk, particularly with powerful larger

engines, of the propeller flying off if the prop

nut loosens due to detonation ("knocking") in

the combustion chamber when the engine is

operated too lean, or under an excessively

heavy load.

Obviously, this can be very hazardous. To

eliminate such dangers, the O.S. Locknut

Assembly was devised.

Install this as follows:

Lock Nut

Propeller Washer

Propeller Nut

Ream the propeller shaft hole to 8.1mm

bore with an appropriate reamer, checking

that the hole is exactly centered.

1.

Install the prop to the engine shaft, followed

by retaining washer and prop nut lightly.

Turn the prop counter-clockwise slowly to

locate the position where compression is

felt. At this position, fit the prop horizontally

and tighten firmly the prop nut with a 14mm

wrench.

2.

Add the specially tapered and slotted

locknut and secure with a 12mm wrench

while holding the prop nut with the 14mm

wrench.

3.

Install a spinner assembly to start the

engine with an electric starter.

4.