Carburetor cleanliness – O.S. Engines 21RZ-V01B (P) User Manual

Page 18

Warning!

Mixture adjustments (whether via the Mixture

Control Valve, or the Needle-Valve) cannot be

made accurately under 'no-load' conditions,

which, in any case, are not advised, since such

operation carries the risk of seriously damaging

the engine through over-revving and overheating.

◆

◆

CARBURETOR CLEANLINESS

With the optimum mixture control position, light

smoke is visible during high speed running,and the

engine revolutions increase smoothly during

acceleration. Remember that, if the engine is

operated with the fuel/air mixture slightly too lean, it

will overheat and run unevenly. As with all engines,

it is advisable to set both the needle-valve and

mixture control screw very slightly on the rich side of

the best rpm setting, as a safety measure.

If the engine runs too fast with the throttle closed,

the throttle stop screw should be turned counter-

clockwise to allow the throttle opening to be

reduced.

◆

Finally, beyond the nominal break-in period, a slight

readjustment toward a leaner needle setting may be

required to maintain performance.

The correct functioning of the carburetor depends on

its small fuel orifices remaining clear.

(See Care and Maintenance section on Page19.)

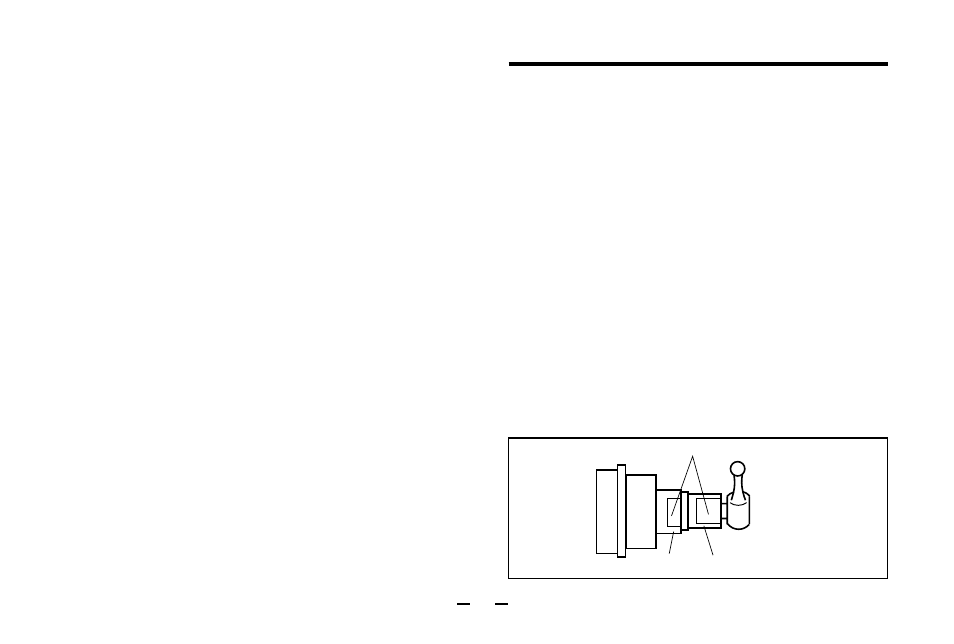

BALL LINK AND SLIDE VALVE EXTENSION

■

When readjusting the position of the Ball Link, always

apply a 6mm spanner (wrench) to the flats in the

Slide Valve Extension, before attempting to loosen or

tighten the ball link retaining screw. Carefully ease

back the Dust Cover bellows to allow access to the

flats. If it should become necessary (e.g. for cleaning)

to disassemble the throttle parts, first unscrew the

Slide Valve guide screw and withdraw the complete

sub-assembly from the carburettor body. Use the

correct size (8mm) wrench when unscrewing the

Slide Valve from the Slide Valve Extension.

'Flats' for spanners

Slide Valve

Slide Valve Extension

17